Preparation device and method for non-woven high polymer material optilene mesh

A technology of a polymer material and a preparation device is applied in the field of preparation of a non-woven polymer material hernia patch, which can solve the problems of low incidence of chronic pain and the like, and achieve good abdominal wall compliance, flexible size and good tissue length. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

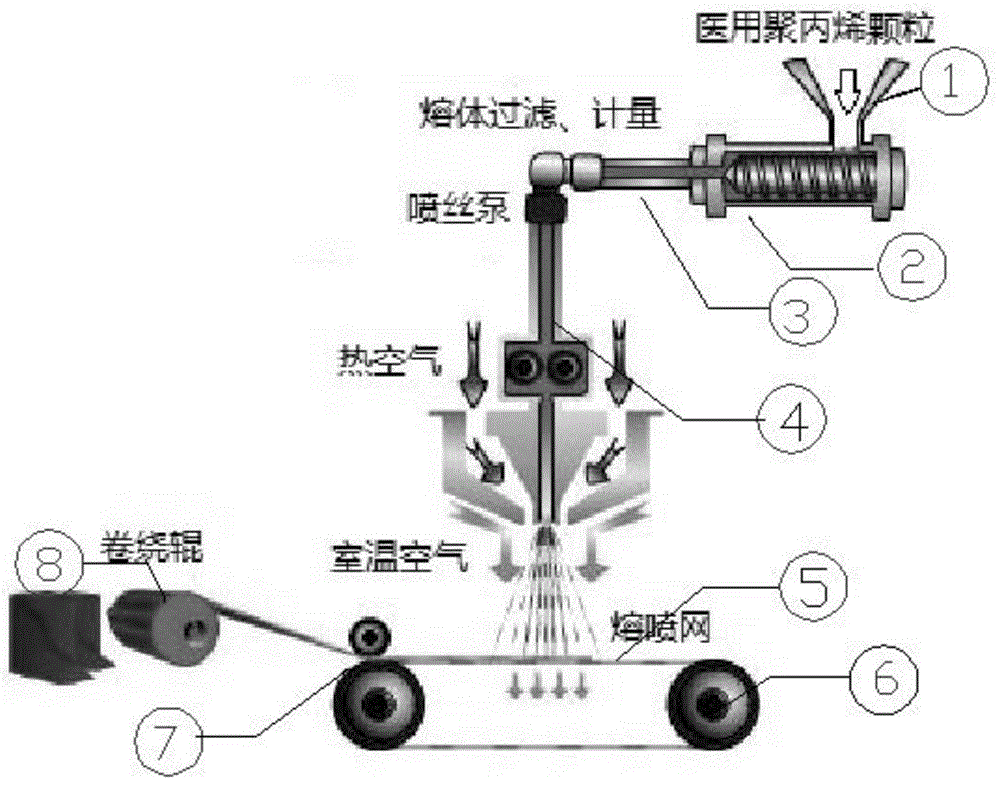

[0037] After the medical polypropylene material is sliced, it is melted at 250°C and the air pressure is 4kg / cm 2 pressure-feeding melt;

[0038] After the melt is filtered and accurately measured, it is sent to the spinneret die;

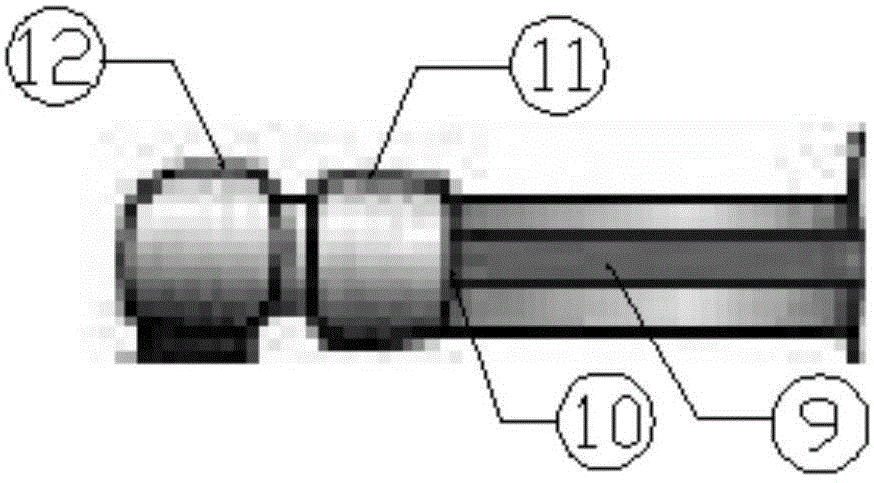

[0039] The melt is extruded from the spinneret hole after passing through the entrance area, the hole flow area and the puffing area;

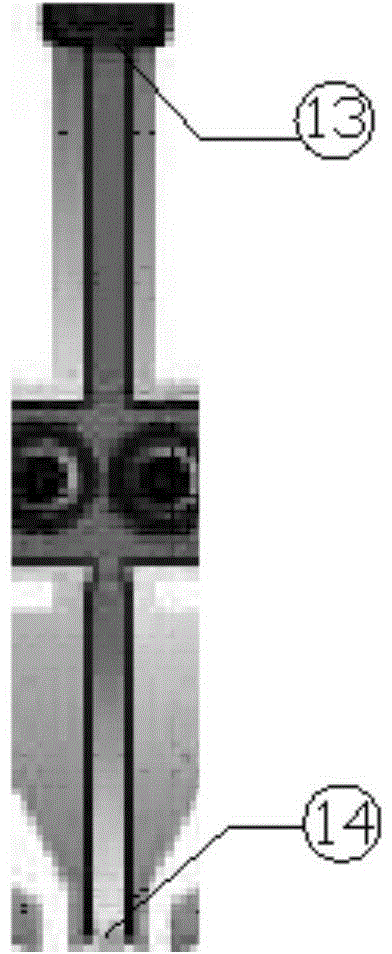

[0040] When the melt expands, under the drafting effect of the high-speed hot air flow at 260°C on both sides, the melt stream is rapidly thinned, and the room temperature air on both sides makes the melt cool and solidify into ultra-fine fibers;

[0041] The drawn and solidified fibers are blown to the melt-blown net (condensed net curtain) under the action of airflow, and the fibers are bonded to form a net by themselves;

[0042] Take the bonded mesh out of the melt blown nozzle for 23cm and wind it on the receiving roller;

[0043] Cut the mesh.

Embodiment 2

[0045] After the medical polypropylene material is sliced, it is melted at 250°C and the air pressure is 4kg / cm 2 pressure-feeding melt;

[0046] After the melt is filtered and accurately measured, it is sent to the spinneret die;

[0047] The melt is extruded from the spinneret hole of the die head after passing through the entrance area, hole flow area and puffing area respectively;

[0048] When the melt expands, under the drafting effect of the high-speed hot air flow at 280°C on both sides, the melt stream is rapidly thinned, and the room temperature air on both sides makes the melt cool and solidify into ultra-fine fibers;

[0049] The drawn and solidified fibers are blown to the melt-blown net (condensed net curtain) under the action of airflow, and the fibers are bonded to form a net by themselves;

[0050] Take the bonded mesh out of the melt blown nozzle for 23cm and wind it on the receiving roller;

[0051] Cut the mesh.

Embodiment 3

[0053] After the medical polypropylene material is sliced, it is melted at 250°C and the air pressure is 4kg / cm 2 pressure-feeding melt;

[0054] After the melt is filtered and accurately measured, it is sent to the spinneret die;

[0055] The melt is extruded from the spinneret hole of the die head after passing through the entrance area, hole flow area and puffing area respectively;

[0056]When the melt expands, under the drafting effect of the high-speed hot air flow at 300°C on both sides, the thin stream of the melt is rapidly thinned, and the air at room temperature on both sides makes the melt cool and solidify into ultra-fine fibers;

[0057] The drawn and solidified fibers are blown to the melt-blown net (condensed net curtain) under the action of airflow, and the fibers are bonded to form a net by themselves;

[0058] Take the bonded mesh out of the melt blown nozzle for 23cm and wind it on the receiving roller;

[0059] Cut the mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length and width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com