A steel-bamboo composite box girder

A combination box and steel bamboo technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of slow growth of forest resources, scarcity of wood resources, insufficient total resources, etc., achieve good physical and mechanical properties and processing performance, improve Economic indicators, good structural integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

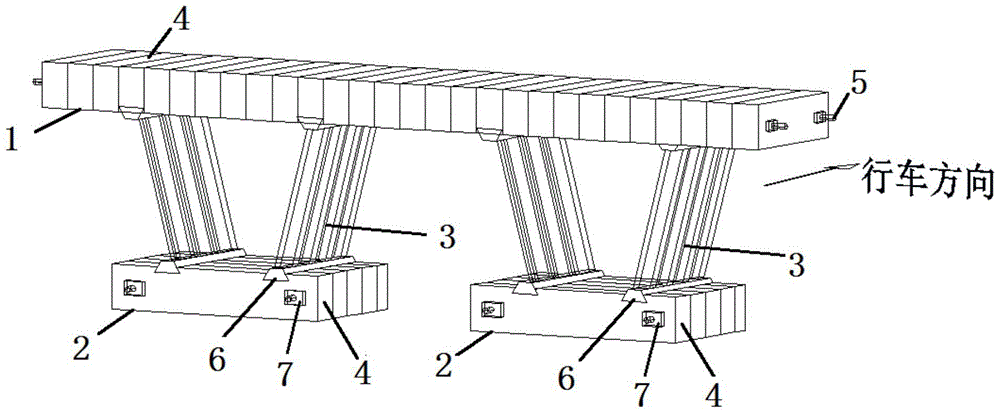

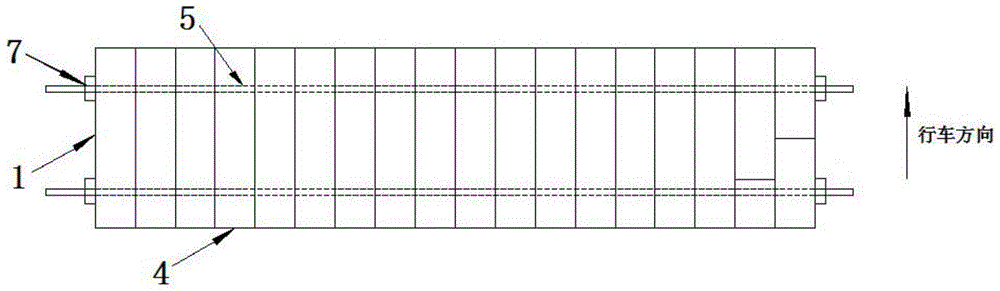

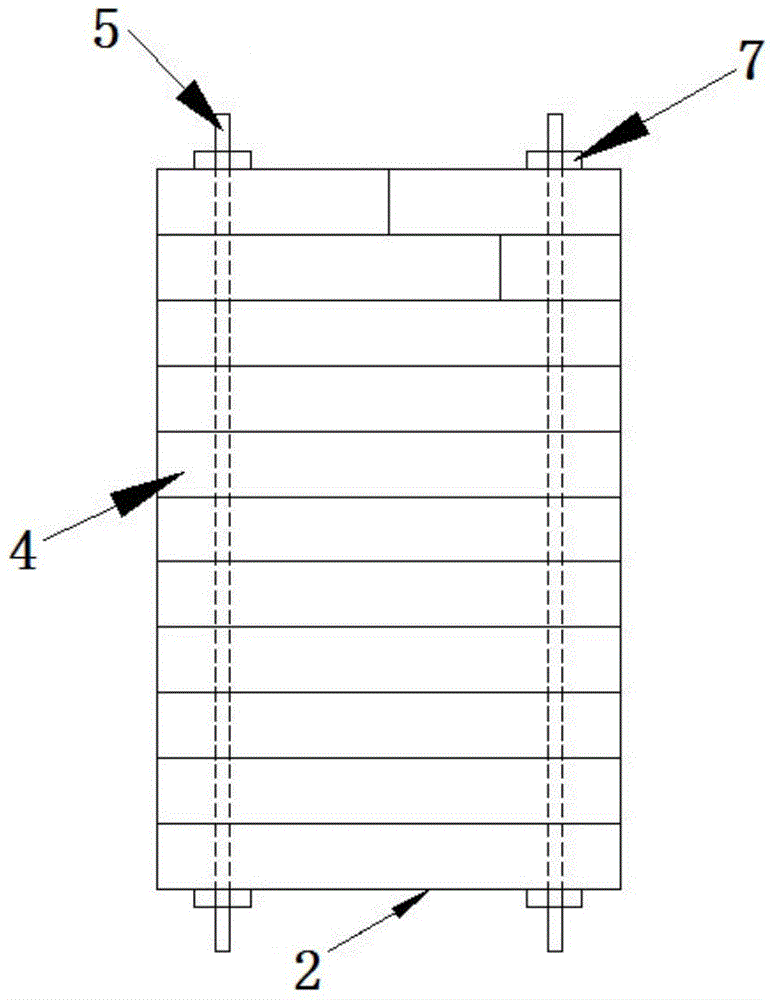

[0031] Example: refer to the figure 1 to 4 As shown, a steel-bamboo composite box girder, including the roof 1 ,as well as 2 one on top 1 bottom plate 2 , each baseplate 2 with top plate 1 Between two corrugated steel webs arranged symmetrically 3 connection, top plate 1 It consists of a number of single-piece bamboo plywood arranged side by side at the same height and whose length is set along the driving direction of the bridge 4 through prestressed steel bars 5 pressed together, base plate 2 Consists of several single-piece bamboo plywood boards arranged side by side with the same height and length along the width direction of the bridge 4 through prestressed steel bars 5 compacted, while corrugated steel webs 3 with top plate 1 and base plate 2 between shear steel sheets 6 connect.

[0032] The present invention is on the roof 1 and base plate 2 There are prestressed steel bars inside 5 through the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com