Vegetable greenhouse structure system with chord support steel structure

A vegetable greenhouse and string support steel technology, which is applied in the field of string support steel structure vegetable greenhouse structure system, can solve the problems of inconvenient operation and management, insufficient service life, poor wind and snow resistance, and achieves clear force and material saving. , the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

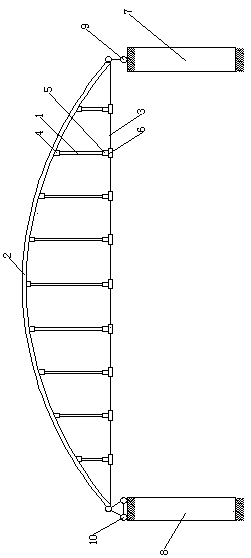

[0014] like figure 1 As shown, the structural system of the suspensive steel structure vegetable greenhouse is mainly composed of vertical struts 1, arched bending and compressive rigid members 2, tensile flexible members 3, right pillar 7, and left pillar 8. 3 Prestressing is applied to reduce the burden of the arched bending and compressive rigid member 2; the vertical braces 1 are round steel pipes arranged vertically and parallel at equal intervals; the arched bending and compressive rigid members 2 and the vertical braces 1 are connected by the upper steel pipe 4 welded on the bottom surface of the arched flexural compression rigid member 2; the vertical strut 1 and the tensile flexible member 3 are connected by the lower steel pipe 5 welded on the two-way pipe 6, so The above-mentioned two-way pipe 6 is set on the tensile flexible member 3; the left and right ends of the arched bending-resistant and compressive rigid member 2 and the tensile flexible member 3 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com