Preparation method of basalt fiber stick for concrete

A basalt fiber and concrete technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problem of insufficient connection force between basalt fiber and concrete, and achieve the effect of ensuring tensile strength and improving connection force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

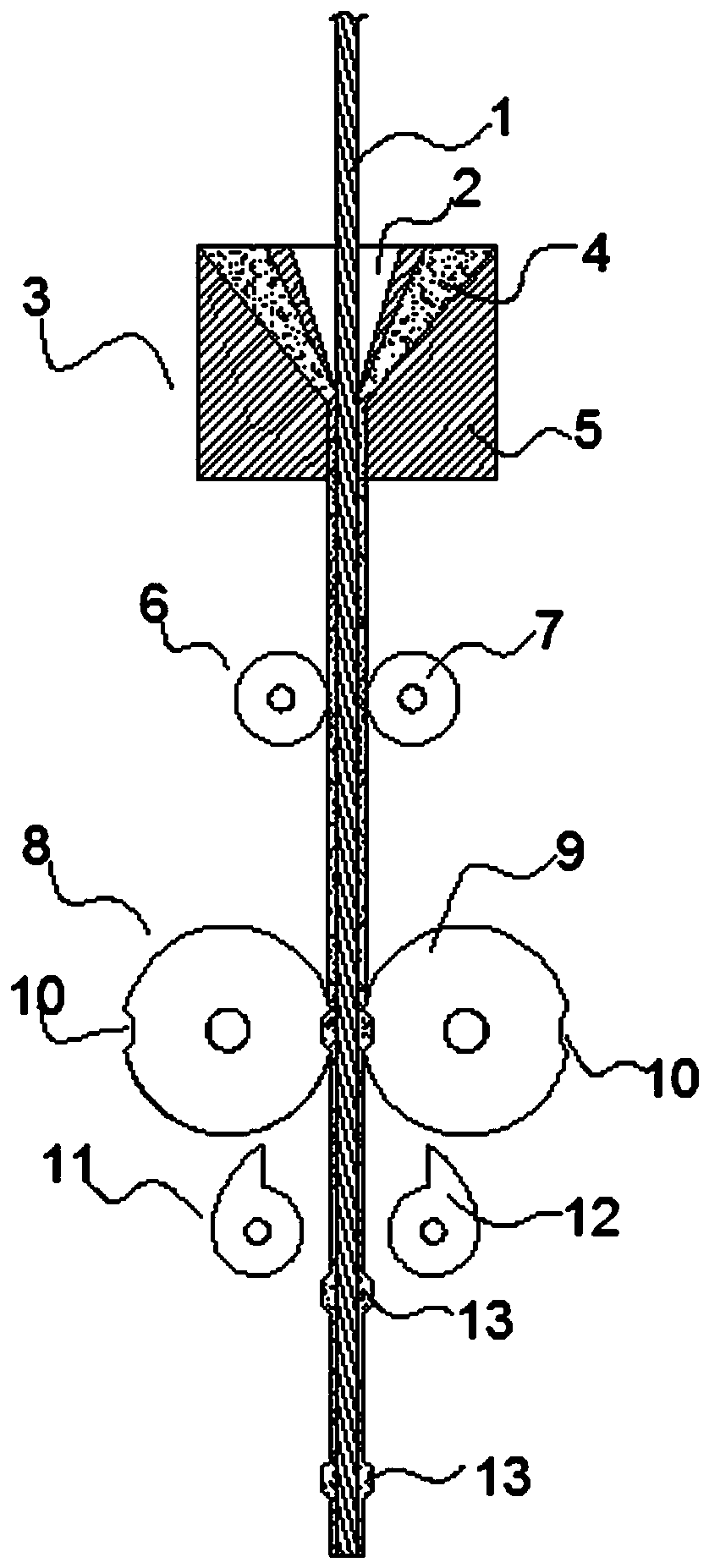

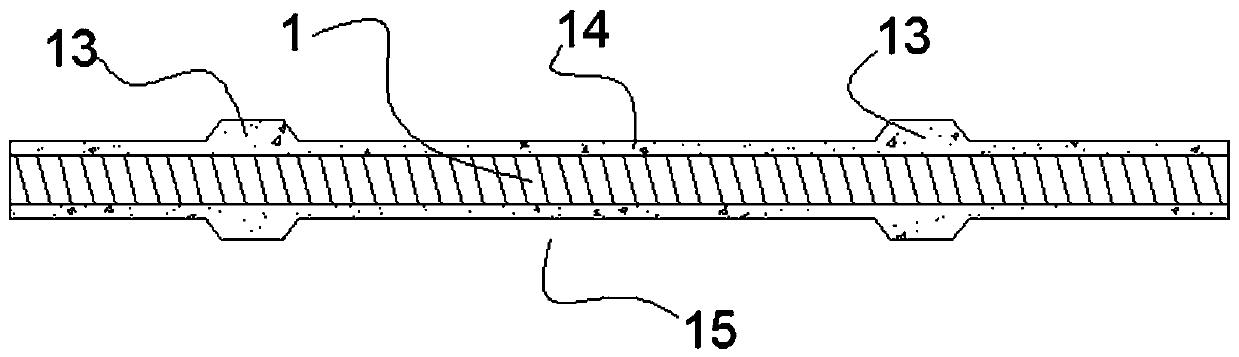

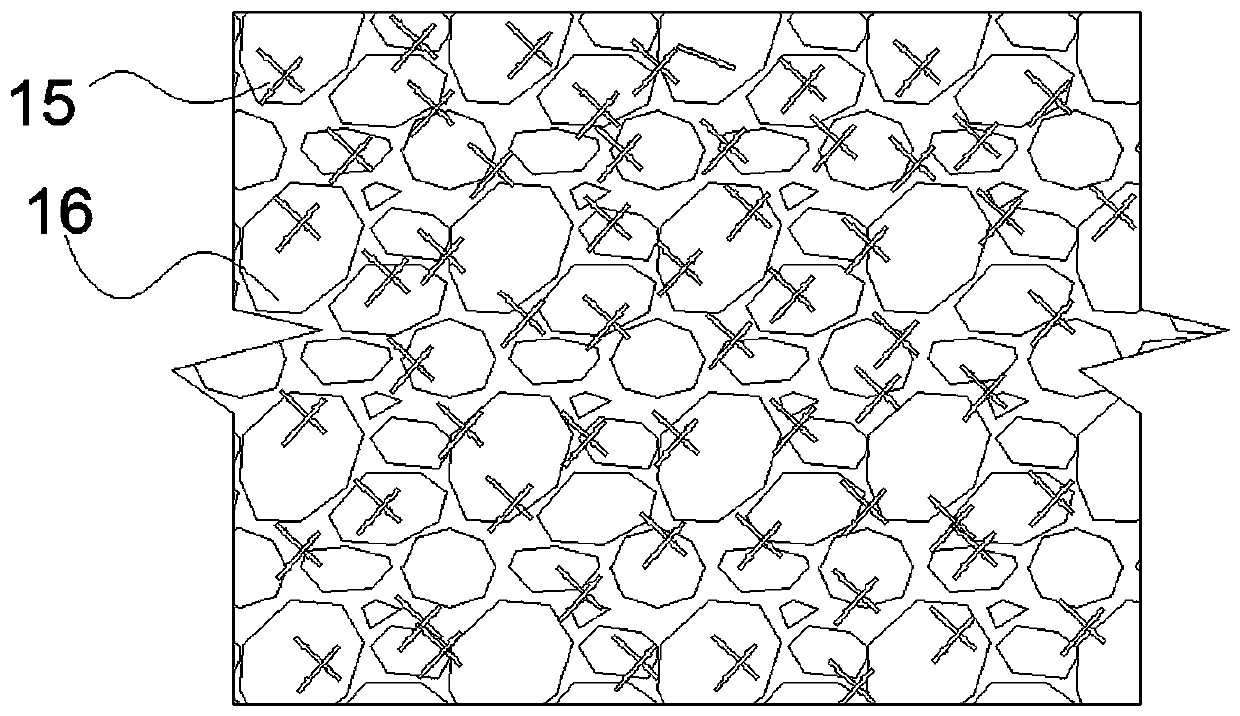

[0014] A kind of embodiment of the preparation method of basalt fiber stick for concrete Figure 1~3 Shown:

[0015] The preparation method uses a preparation device to prepare basalt fiber sticks. The preparation device includes an encapsulating device 3, a conveying device 6, a reinforced structure forming device 8 and a fiber bundle cutting device 11 arranged in sequence along the conveying direction of the basalt fiber bundle.

[0016] Wherein the gluing device belongs to the prior art, the more common one is a cable gluing machine, which includes a gluing device seat 5, on which the basalt fiber bundle 1 is provided with a fiber bundle passage 2 and a fiber bundle passage 3 There is a glue injection channel on the periphery, and the glue injection channel communicates with the fiber bundle channel. When in use, the basalt fiber bundle passes through the fiber bundle channel, and the melted glue 4 enters the fiber bundle channel through the glue injection channel and wraps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com