Rotary air compressor

An air compressor and rotary technology, applied in the field of compressors, can solve the problems of high machining accuracy, assembly technology and lubrication system, large wear and tear of the piston, and large friction, so as to achieve less damage and improve energy utilization rate, the effect of reducing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

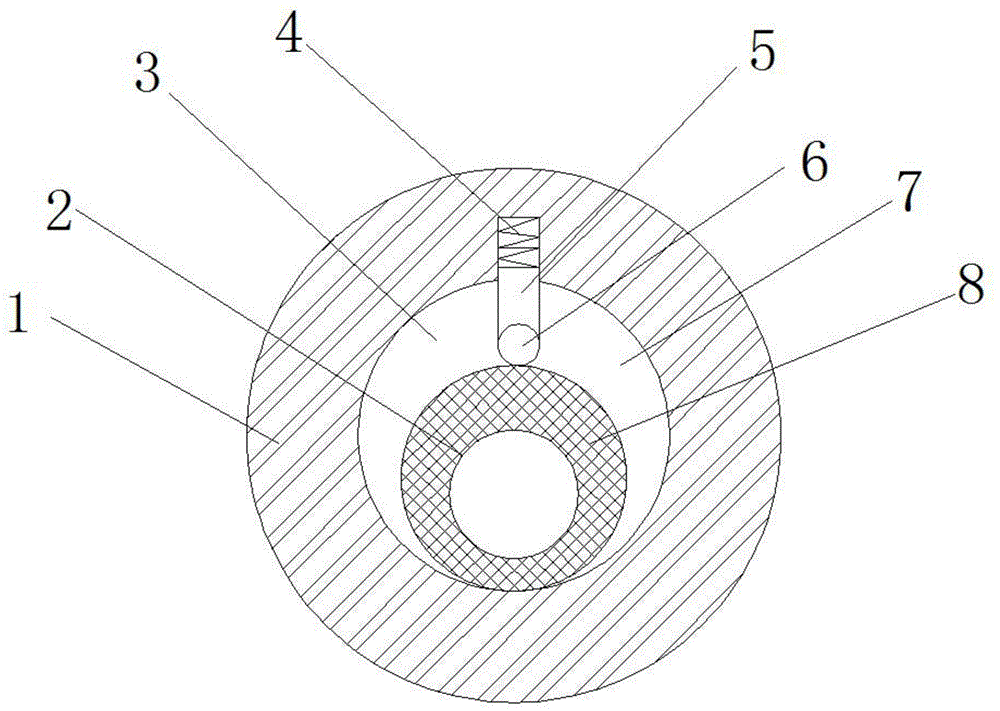

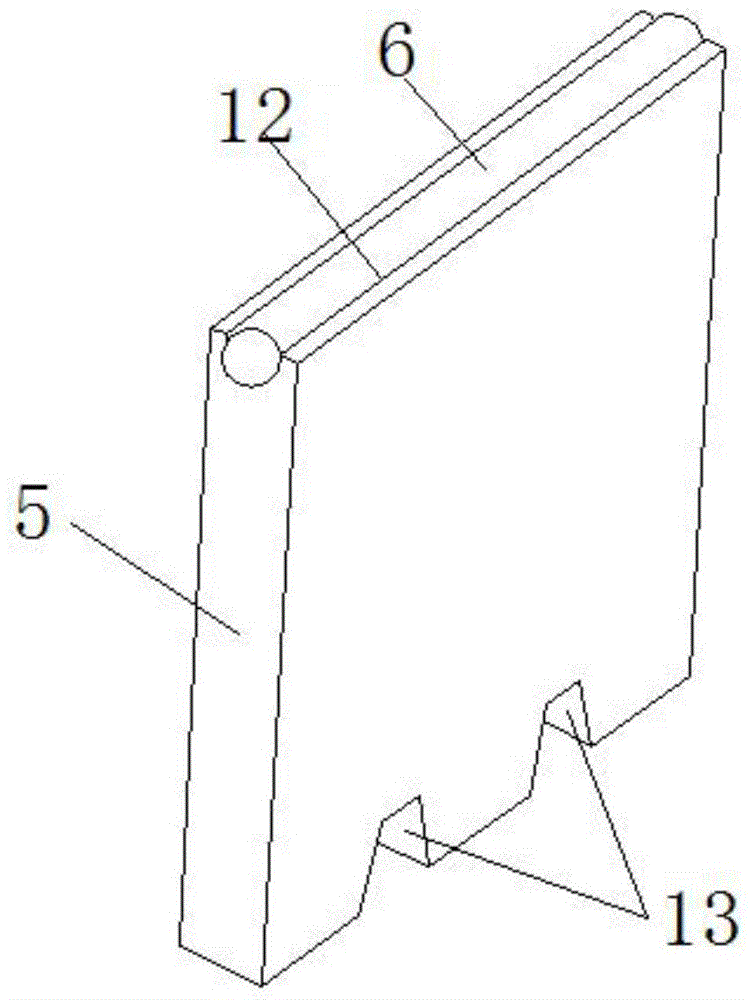

[0015] The structure diagram of rotary air compressor shown in Fig. 1, cylinder 1 is its stator, and rolling piston 8 is arranged eccentrically in cylinder 1, as its rotor, and it is driven by rotating shaft 2, and piston 8 is tangent to the inner wall cylindrical surface of cylinder 1, Sliding plate 5 is housed in the cylinder body (the structure of sliding plate 5 is as figure 2 Shown), the root of the slide plate 5 is located in the cylinder body and has a spring groove 13, there is a spring 4 between the slide plate 5 and the cylinder 1, and the top of the slide plate 5 has a transverse U-shaped or arc-shaped groove. A ball-head needle roller 6 is placed in the groove, the needle roller 6 can roll in the groove, the needle roller 6 is exposed to the groove, and the elastic force of the spring 4 makes the needle roller 6 close to the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com