Shell type capacitor assembling method

An assembly method and capacitor technology, applied to capacitors, electrical components, etc., can solve problems such as high cost, troublesome manufacturing, inconsistent sizes, etc., and achieve the effect of avoiding displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

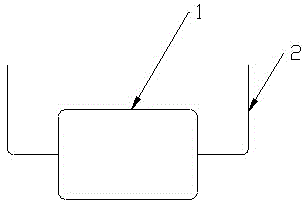

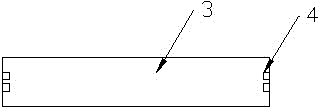

[0017] Such as figure 1 , figure 2 From the schematic diagram shown, it can be seen that the shell-type capacitor manufactured by the assembly method includes a capacitor body and a case for accommodating the embedding of the capacitor body.

[0018] The main body of the capacitor includes a capacitor core 1. The capacitor core 1 is a parallel cylindrical body formed by winding a thin film with the middle layer as an insulating medium and the upper and lower layers of metal plating. Both ends of the capacitor core 1 are A tin-zinc alloy metal block is provided, and a pair of symmetrically arranged L-shaped electrodes 2 are respectively welded on the two tin-zinc alloy metal blocks.

[0019] The housing 3 is a flat hollow cuboid, and one end of the housing 3 has an opening into which the main body of the capacitor is embedded, and a limiting mechanism for limiting the electrodes is provided on the inner wall of the housing 3 .

[0020] The limit mechanism includes a pair of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com