Wideband triangular wave control system based on step-down type constant current

A constant current, control system technology, applied in the field of electronics, can solve the problems of unstable voltage and current, low power utilization, low voltage amplitude, etc., to achieve the effect of wide frequency range, high power utilization and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

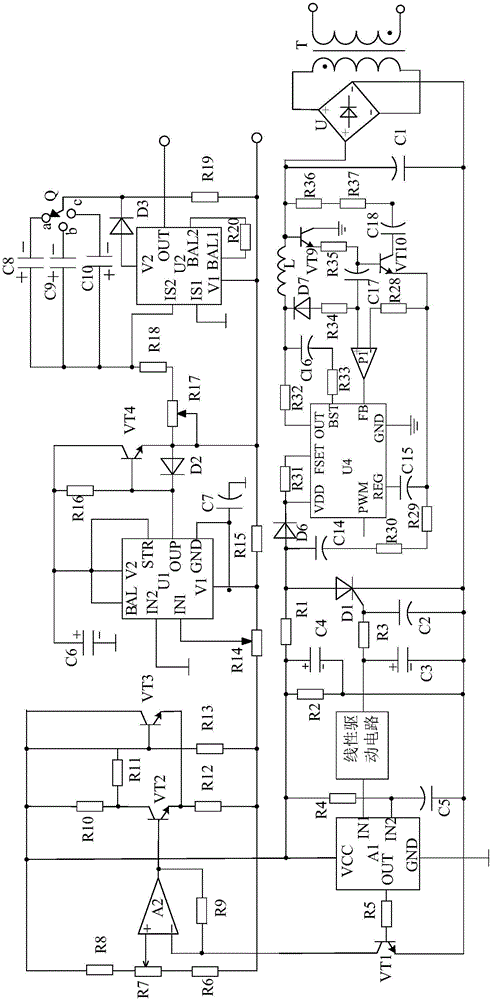

[0023] Such as figure 1 As shown, the present invention consists of a front-end power supply circuit, a protection circuit and a resonant circuit connected to the output end of the front-end power supply circuit, a comparison circuit and a trigger circuit connected to the resonant circuit, and a triangular wave control circuit connected to the trigger circuit. It consists of a linear drive circuit between the circuit and the resonant circuit, and a step-down constant current circuit connected in series between the front-end power supply circuit and the protection circuit.

[0024] Among them, the step-down constant current circuit consists of step-down chip U4, transistor VT9, transistor VT10, amplifier P1, resistor R28, resistor R29, resistor R30, resistor R31, resistor R32, resistor R33, resistor R34, resistor R35, resistor R36, The resistor R37, the capacitor C14, the capacitor C15, the capacitor C16, the capacitor C17, the capacitor C18, the diode D6, and the diode D7 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com