A submergible cleaning system

一种清洁系统、潜式的技术,应用在可潜式清洁系统的用途领域,能够解决清洁质量不符合要求等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

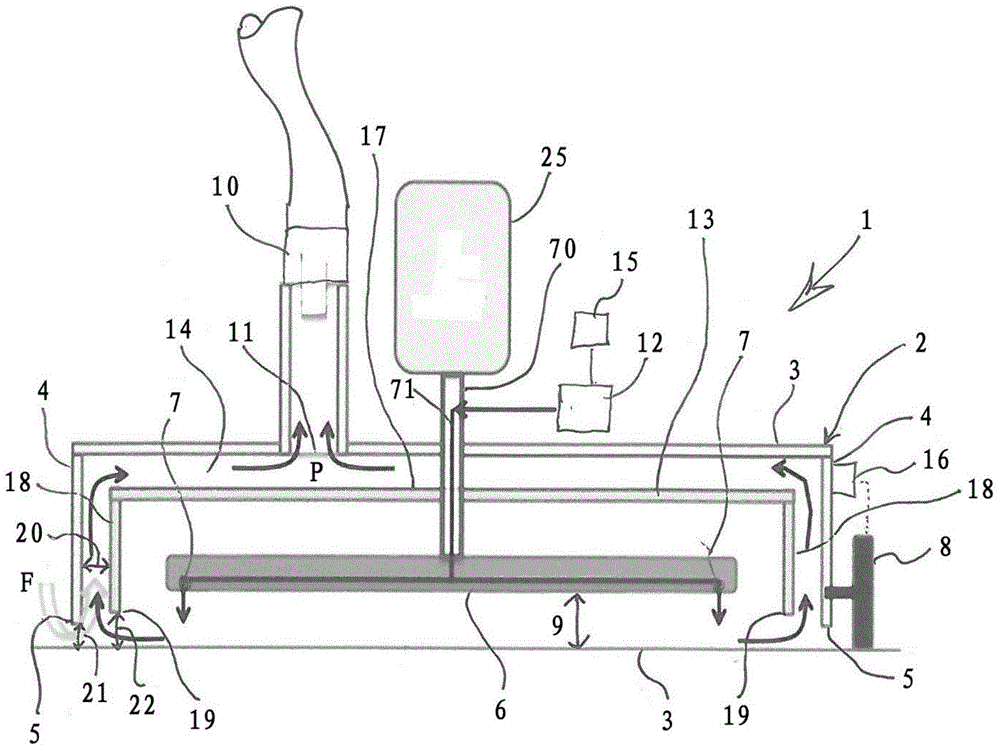

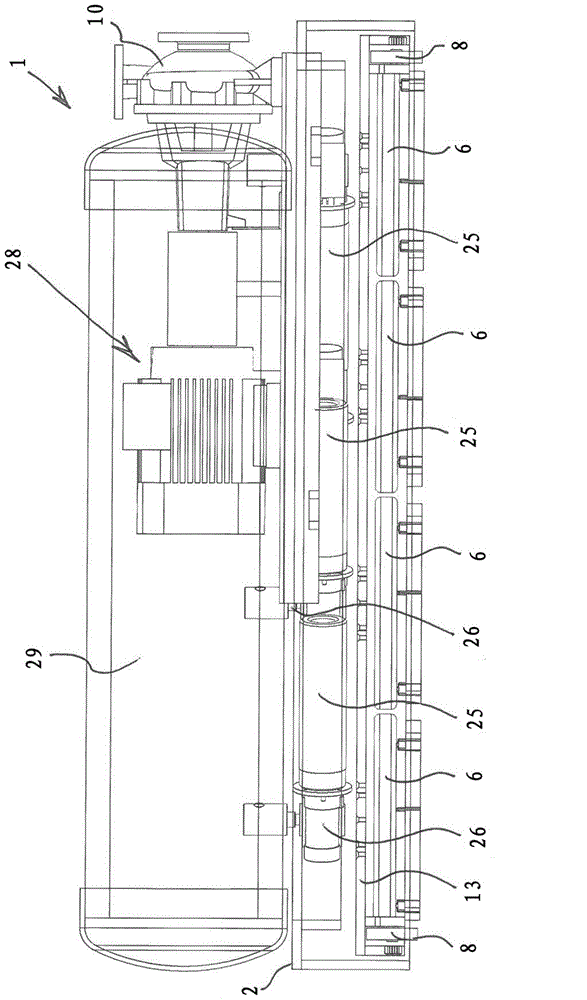

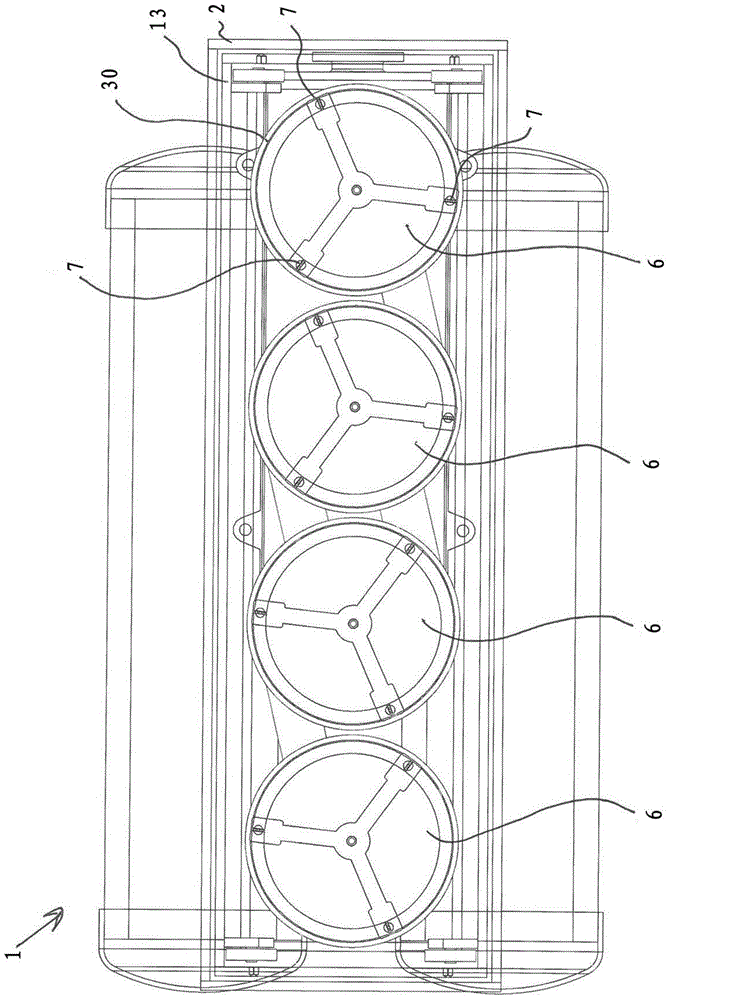

[0087] exist figure 1 In , a submersible cleaning system 1 for cleaning the underwater hull surface 3 of a vessel while the vessel is afloat is shown. The cleaning system 1 comprises a housing 2 comprising a top surface 3, a side surface 4 with an edge 5 and an open bottom surface arranged opposite the hull surface 3 in cleaning position. The housing 2 also includes a rotating disc 6 having a plurality of nozzles 7 arranged around the periphery of the rotating disc 6 , the nozzles 7 facing the hull surface 3 . The housing 2 also comprises rolling spacers 8 for providing a predetermined first gap 9 between the rotating disc 6 and the hull surface 3 . A suction device 10 , such as a pump, is fluidly connected to an outlet 11 provided in the housing 2 for providing a negative pressure P inside the housing 2 .

[0088] Furthermore, the cleaning system 1 comprises a pressurizing device 12 fluidly connected to the nozzle 7 for supplying high pressure fluid to the nozzle 7, whereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com