Rechargeable battery cell and rechargeable battery module

A battery module, battery technology, applied in the directions of large flat cells/batteries, small-sized cells/batteries, batteries, etc., can solve problems such as short circuits, hindering tool accessibility, and inability to achieve electrical insulation of connecting electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

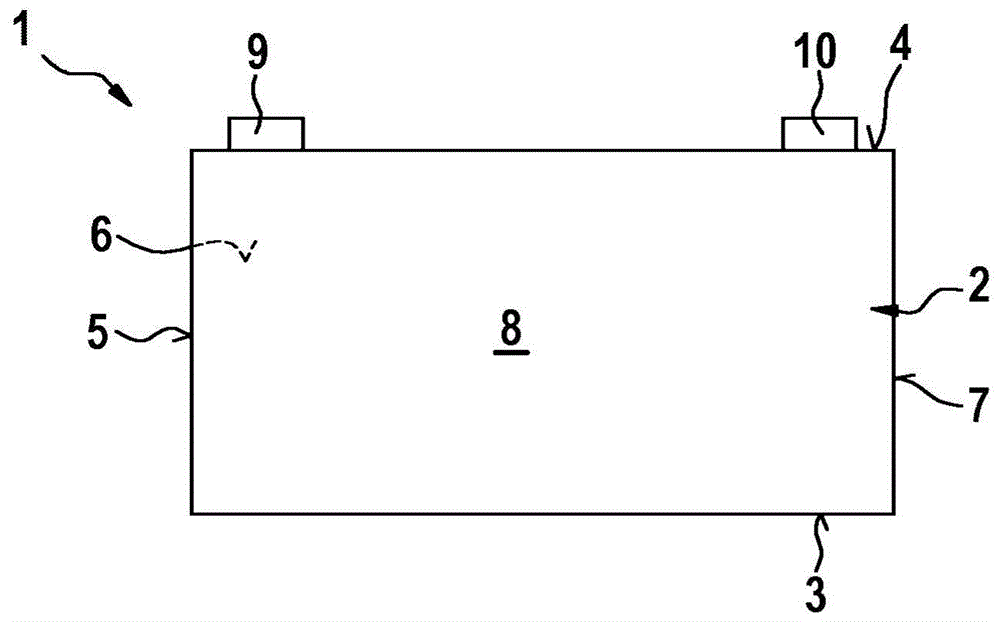

[0020] figure 1 The longitudinal sides of a conventional battery cell 1 are schematically shown. The battery cell 1 comprises a cell housing 2 having a base 3 , a cover 4 and side walls 5 to 8 connecting the base 3 to the cover 4 . The cell housing 2 is formed in the form of a square in the battery cell 1 . The base 3 , the cover 4 and the side walls 5 to 8 are thus formed in a rectangular shape.

[0021] The cover part 4 is designed to extend in the longitudinal direction and has two openings, not further shown, arranged along its longitudinal extension parallel to the drawing plane and two ends arranged opposite one another with reference to its longitudinal extension, wherein the second one end at figure 1 and figure 2 Arranged at the end of the cover 4 shown on the left, and the second end at figure 1 and figure 2 is arranged at the end of the cover part 4 shown on the right. The connecting electrodes 9 or 10 are each guided through one of the openings. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com