Preparation method of supported metal catalysts

A metal catalyst, supported technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. less difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

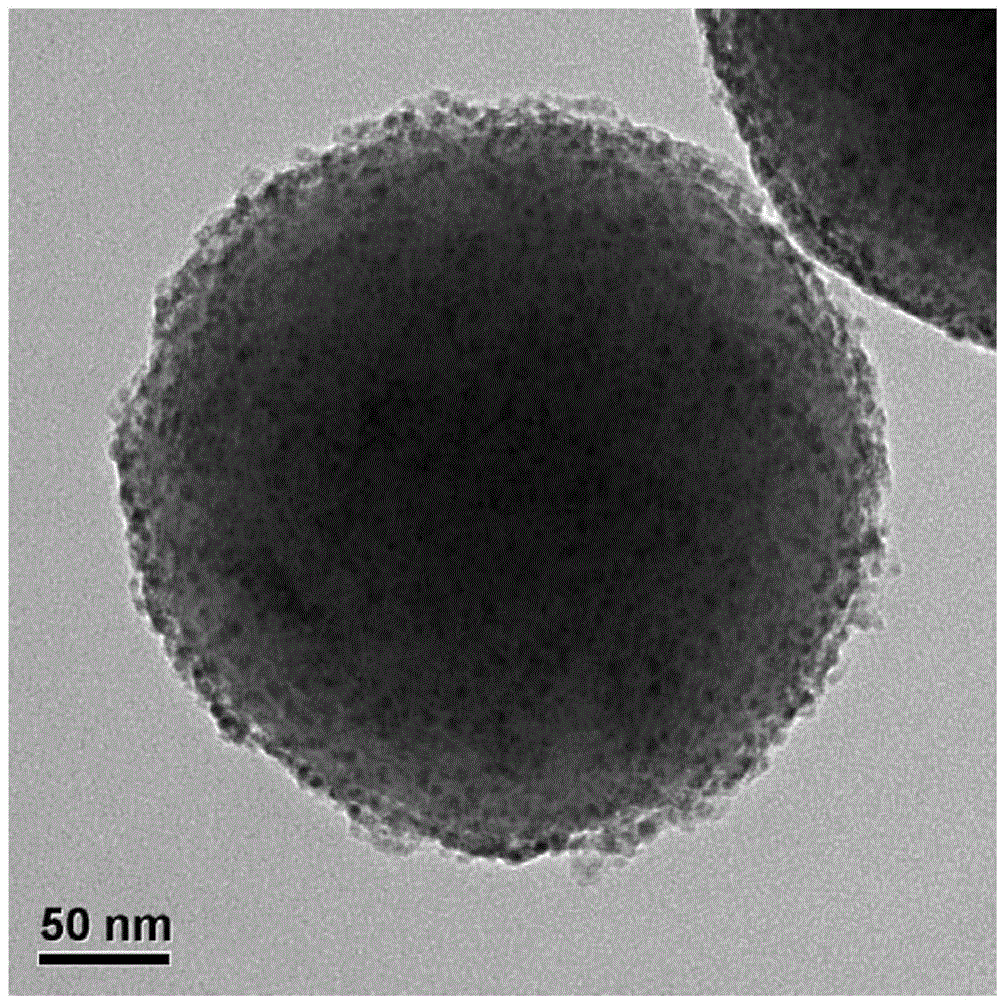

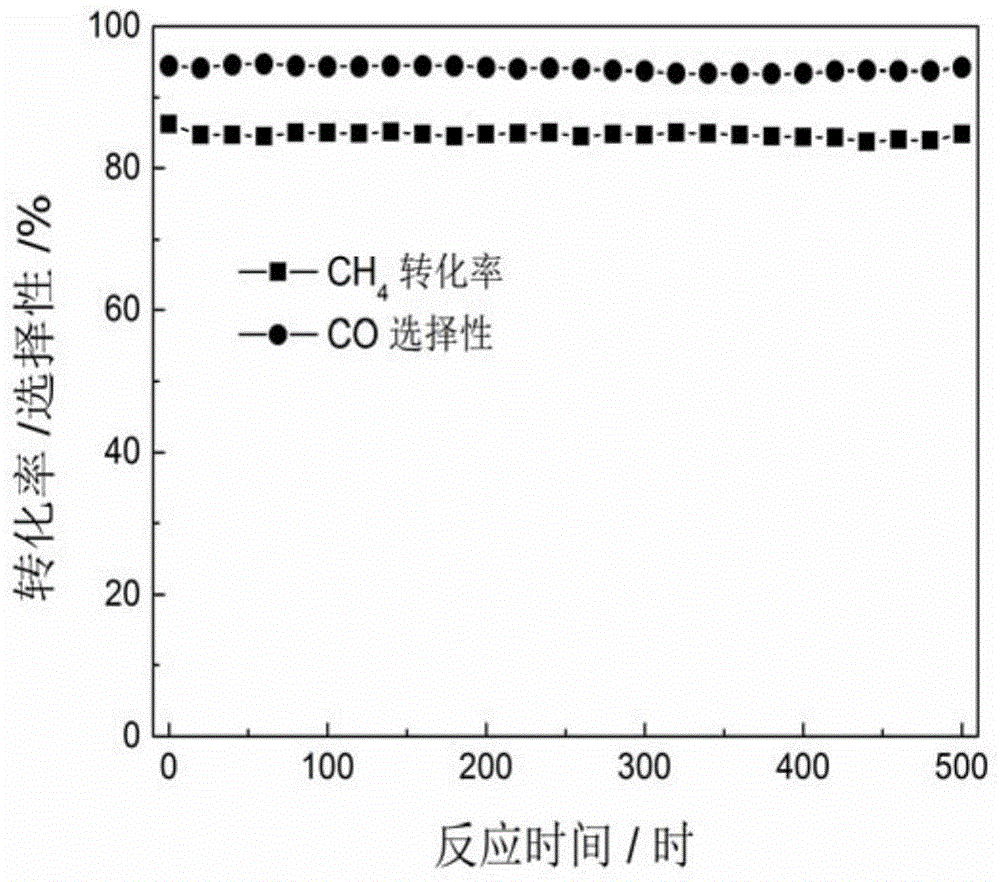

Image

Examples

Embodiment 1

[0027] Weigh cobalt nitrate, silicon dioxide, and arginine with mass percentages of 0.1%, 10%, and 0.01%, respectively, and add them to 1 ton of water, and stir to mix evenly. Dry at 150°C, bake at 600°C, and heat at 600°C 2 Reduction to get Co / SiO 2 supported catalyst.

Embodiment 2

[0029] The mass percentages in Example 1 were replaced by 10%, 20%, and 8%, and arginine was replaced by methylamine to obtain Co / SiO 2 supported catalyst.

Embodiment 3

[0031] The mass percentages in Example 1 are replaced by 20%, 60%, and 10% in turn to obtain Co / SiO 2 supported catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com