Combined type steel ladle permanent layer casting body

A pouring body and permanent layer technology, which is used in casting molten material containers, manufacturing tools, metal processing equipment, etc., can solve the problems of undiscovered composite ladle permanent layer technical reports, waste of resources, etc., and achieve excellent slag corrosion resistance. The effect of reducing manufacturing costs and alleviating resource shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

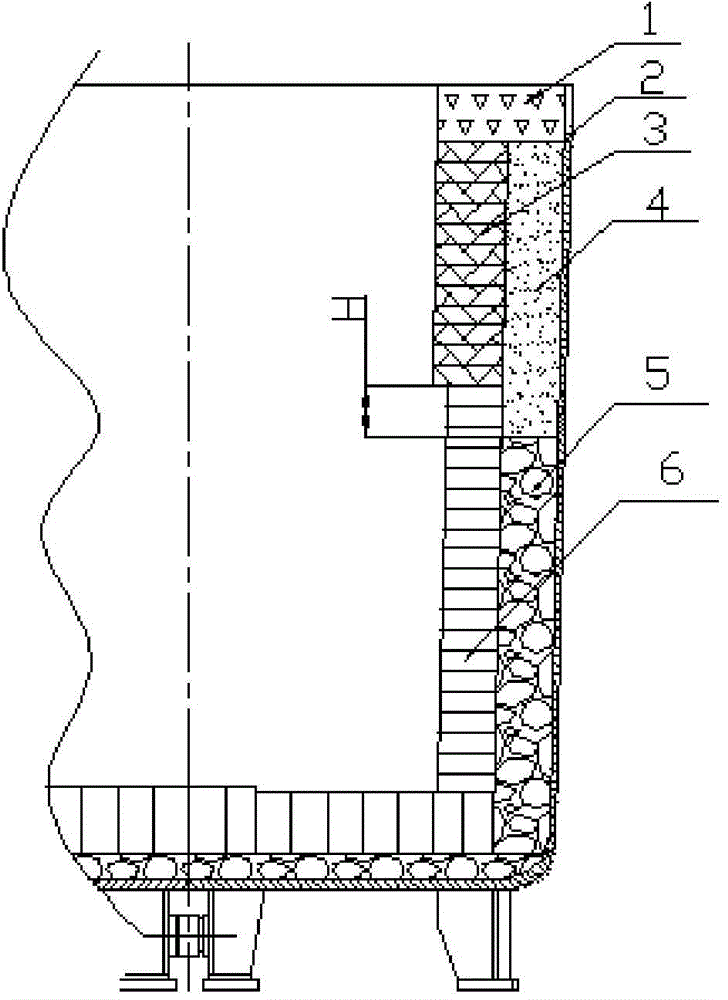

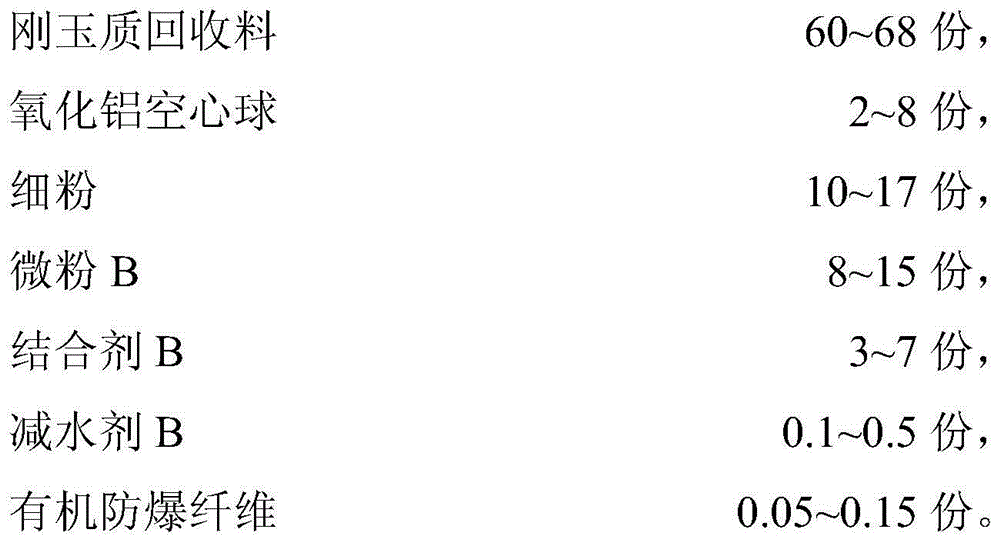

[0028] Such as figure 1 Shown: a composite ladle permanent layer pouring body, which includes the upper part 4 of the pouring body and the lower part 5 of the pouring body. position, the height difference of which is H=500-600mm; the upper part 4 of the castable body is casted with magnesium-chromium castable; the lower part 5 of the castable body is casted with aluminum-magnesium castable prepared from corundum recycled materials;

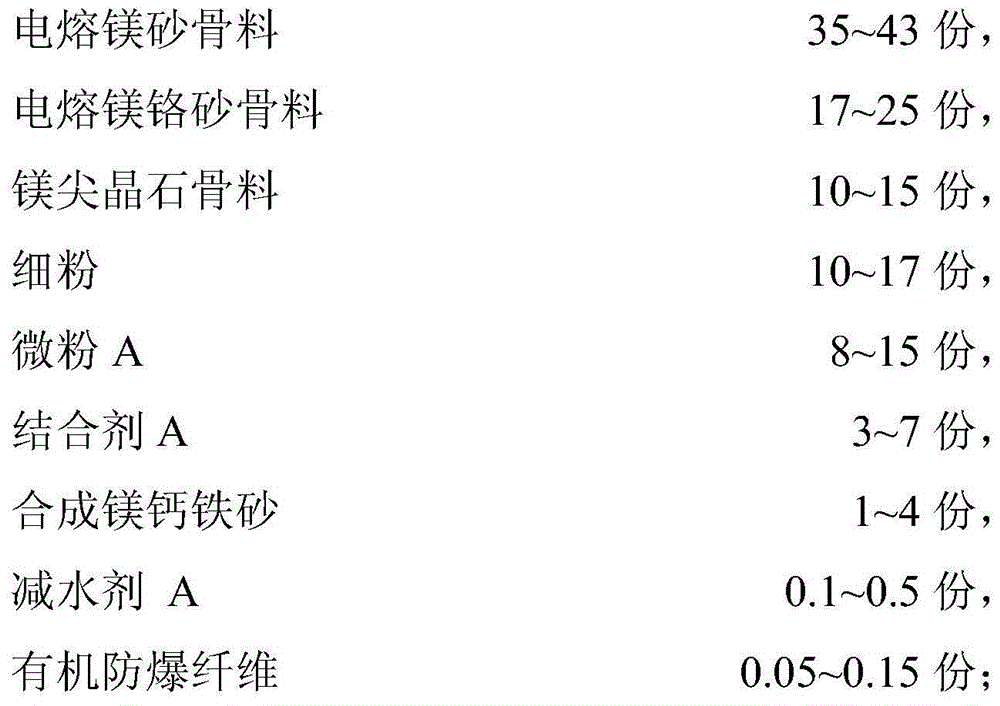

[0029] The weight and number ratio of each component in the magnesium chromium refractory castable is:

[0030]

[0031] Wherein, the fine powder is composed of component A and component B, component A is fused white corundum, component B is aluminum-magnesium spinel, and the weight ratio is 1-2:1. The micropowder A is SiO 2 The mixture of fine powder and active MgO fine powder has a weight ratio of 1:10.

[0032] The fused magnesia aggregate is classified according to particle size: 12mm2 Micropowder, SiO 2 Content ≥ 92%, particle size ≤ 5...

Embodiment 2

[0038] Such as figure 1 Shown: a composite ladle permanent layer pouring body, which includes the upper part 4 of the pouring body and the lower part 5 of the pouring body. position, the height difference of which is H=500-600mm; the upper part 4 of the castable body is casted with magnesium-chromium castable; the lower part 5 of the castable body is casted with aluminum-magnesium castable prepared from corundum recycled materials;

[0039] The weight and number ratio of each component in the magnesium chromium refractory castable is:

[0040]

[0041] Wherein, the fine powder is composed of component A and component B, component A is sintered tabular alumina, component B is aluminum magnesium spinel, and the weight ratio is 1-2:1. The micropowder is SiO 2 The mixture of fine powder and active MgO fine powder, the mixing ratio is 1:20.

[0042] Fused magnesia aggregate is divided into five grades according to particle size: 12mm2 Micropowder, SiO 2 Content ≥ 92%, partic...

Embodiment 3

[0048] Such as figure 1 Shown: a composite ladle permanent layer pouring body, which includes the upper part 4 of the pouring body and the lower part 5 of the pouring body. position, the height difference of which is H=500-600mm; the upper part 4 of the castable body is casted with magnesium-chromium castable; the lower part 5 of the castable body is casted with aluminum-magnesium castable prepared from corundum recycled materials;

[0049] The parts by weight of each component in the magnesium-chromium refractory castable are:

[0050]

[0051] Wherein, the fine powder is composed of A component and B component, the A component is sintered tabular corundum, and the B component is fused magnesia with MgO content ≥ 97%, and the weight ratio is 1-2: 1. The A micropowder is SiO 2 The mixture of fine powder and active MgO fine powder has a weight ratio of 1:15. The binder A is a mixture of pure calcium aluminate cement and hydrated magnesium oxide.

[0052] The fused magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com