Reducer for vacuum-extruder

A technology of vacuum extruder and reducer, which is applied in the field of brick and tile manufacturing, and can solve problems such as poor mud pressing effect, long distance between axes, and large working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

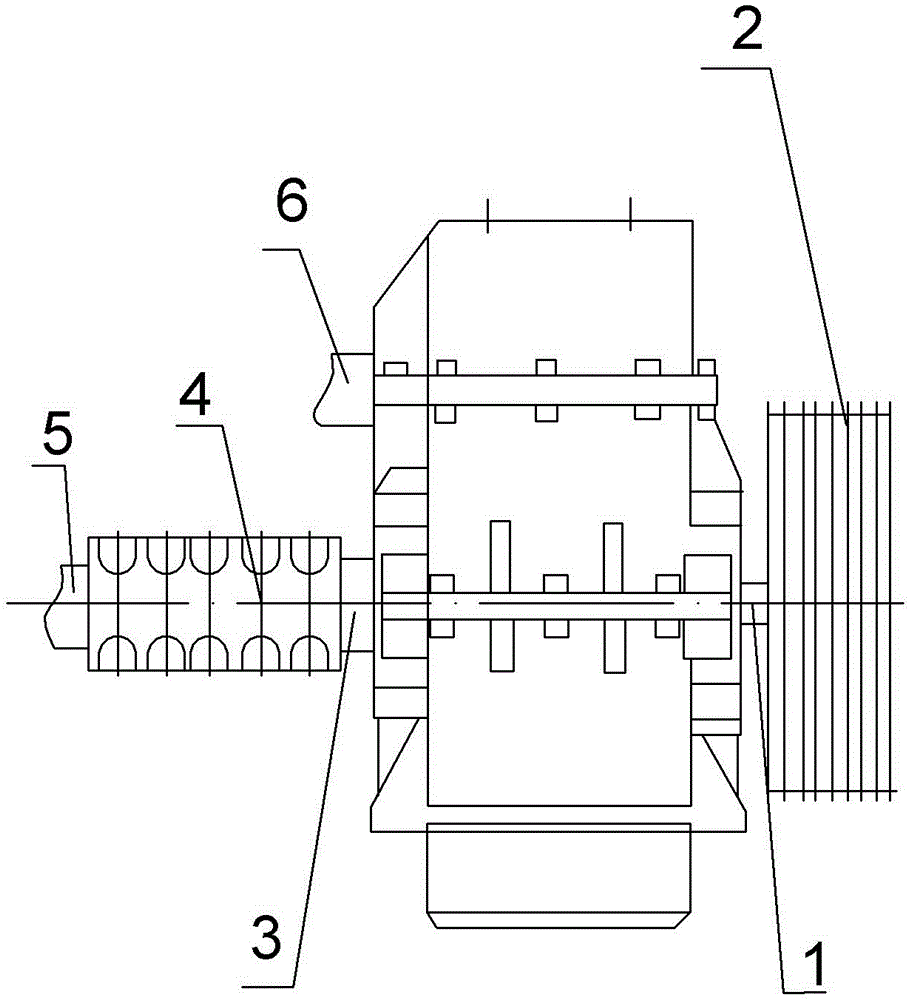

[0012] The present invention will be described in further detail below by way of specific implementation: as figure 1 As shown, a reducer for vacuum extrusion includes a lower-stage reamer shaft 5, an input high-speed shaft 1, a pneumatic clutch 2, a lower-stage low-speed shaft 3, a clamp coupling 4 and an upper-stage output shaft 6; the pneumatic clutch 2 and the input The high-speed shaft 1 is connected, the input high-speed shaft 1 is connected with the lower low-speed shaft 3, the lower low-speed shaft 3 is connected with the clamp coupling 4, the clamp coupling 4 is connected with the lower reamer shaft 4, and the upper output shaft 6 includes the first The upper stage output shaft and the second upper stage output shaft. The distance between the output shaft of the first upper stage and the output shaft of the second upper stage is 50cm, which avoids the blind area of the mud pressing plate and can make the mud pressing effect better. The reducer is a hard tooth surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com