Preparation method and production facility of high-creep-resistance five-layer oxygen-barrier plastic pipe

A plastic pipe and creep technology is applied in the manufacturing field of high creep resistance five-layer oxygen barrier plastic pipe, which can solve the problems of low production efficiency, difficulty in meeting cross-linking degree requirements and high production cost, so as to improve production efficiency. Efficiency, improving oxygen barrier rate and creep resistance, and reducing the effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

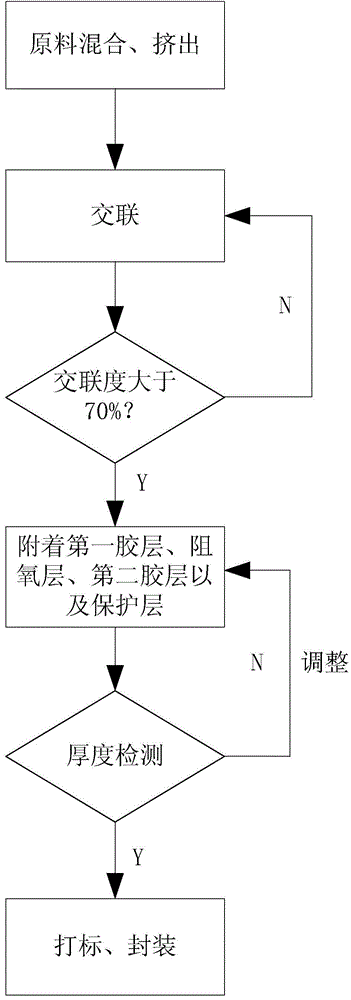

[0029] refer to figure 1 , the present embodiment provides a method for preparing a high-creep-resistant five-layer oxygen-barrier plastic pipe, comprising the following steps:

[0030] A, mix the high-density polyethylene that is 98% by weight, the antioxidant that is 0.1% by weight, and the peroxide that is 0.8% by weight, and mix them uniformly, and carry out extrusion treatment to the mixture under the condition of high temperature and high pressure , to obtain tube embryos, wherein the antioxidant is 3-methyl-6-butyl phenol, and the peroxide is dicumyl peroxide;

[0031] B. Irradiating the tube embryo prepared in step A with infrared light at 230° C. to obtain a crosslinked pe-xa inner tube;

[0032] C. Cool the cross-linked pe-xa inner tube.

[0033] The above technical solution is the core technical solution of this embodiment. In step A, first, the peroxide, antioxidant and high-density polyethylene can be uniformly mixed, so that the crosslinking of the plastic pipe...

Embodiment 2

[0039] This example provides a method for preparing a high-creep-resistant five-layer oxygen-barrier plastic pipe, which is different from Example 1 in that the weight part of polyethylene is 95, the weight part of antioxidant is 0.8, The weight part of the oxide is 0.9, and the tube embryo prepared in step A is irradiated with infrared light at 235°C.

Embodiment 3

[0041] This example provides a method for preparing a high-creep-resistant five-layer oxygen-barrier plastic pipe, which is different from Example 1 in that the weight part of polyethylene is 99.9, the weight part of antioxidant is 0.1, and The weight part of the oxide is 0.1, and the tube embryo prepared in step A is irradiated with infrared light at 240°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com