A spindle dynamic unbalance detection calculation method and system

A technology of dynamic unbalance and calculation method, applied in static/dynamic balance test, measurement device, machine/structural component test, etc., can solve problems such as undiscovered, achieve improved rotation accuracy, low loss, accurate detection and calculation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

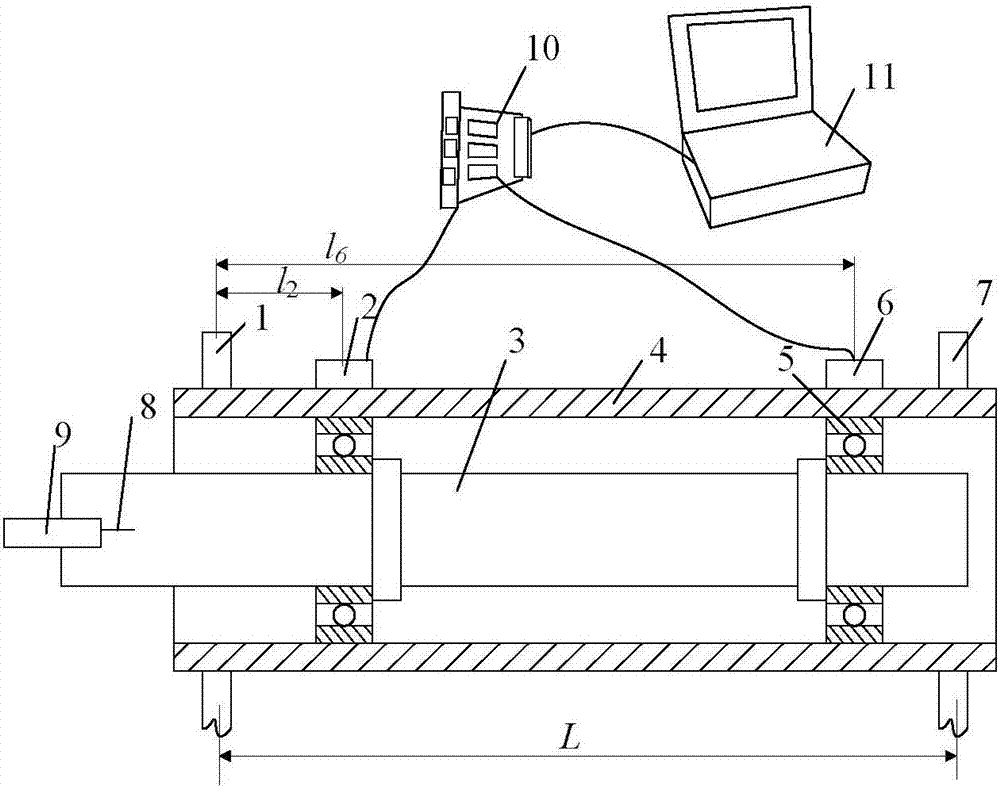

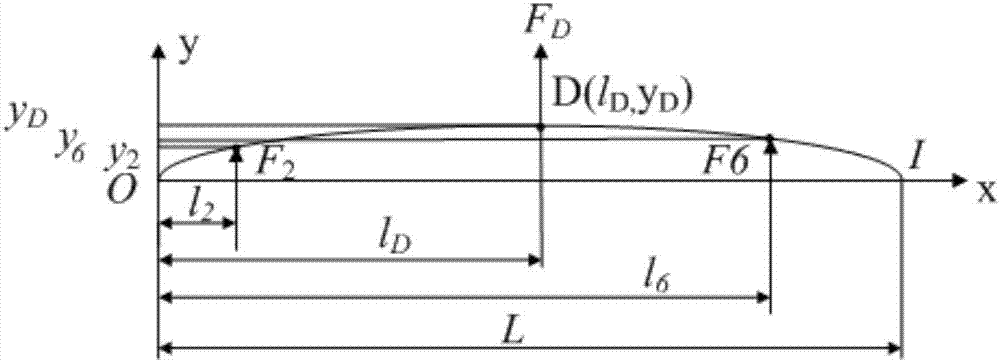

[0025] Example: such as figure 1 As shown, a method for detecting and calculating the dynamic unbalance of the main shaft in the present invention comprises the following steps:

[0026] ① Acquisition of sensor signals: the main shaft is placed in the shaft sleeve, and there are two acceleration sensors to measure the acceleration analog signal caused by the deformation of the shaft sleeve due to the dynamic unbalance of the main shaft; at the same time, the signal of the phase sensor is collected, and the phase sensor Set at the corresponding spindle center mark line to detect and identify the spindle rotation phase mark;

[0027] ②Amplitude-frequency conversion of the signal: convert the collected acceleration analog signal into a time-domain signal through the acquisition card, convert the time-domain signal into a frequency-domain signal; convert the phase sensor signal into a time-domain signal;

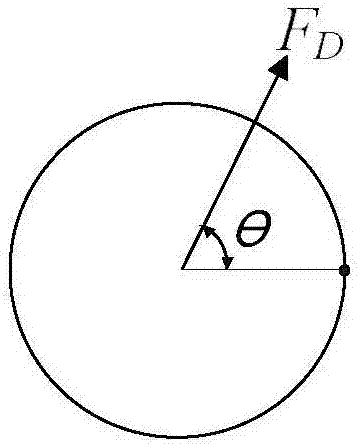

[0028] ③ Extract the same-frequency signal of the spindle speed and determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com