Analysis method of carbon element in Mo1 pure molybdenum

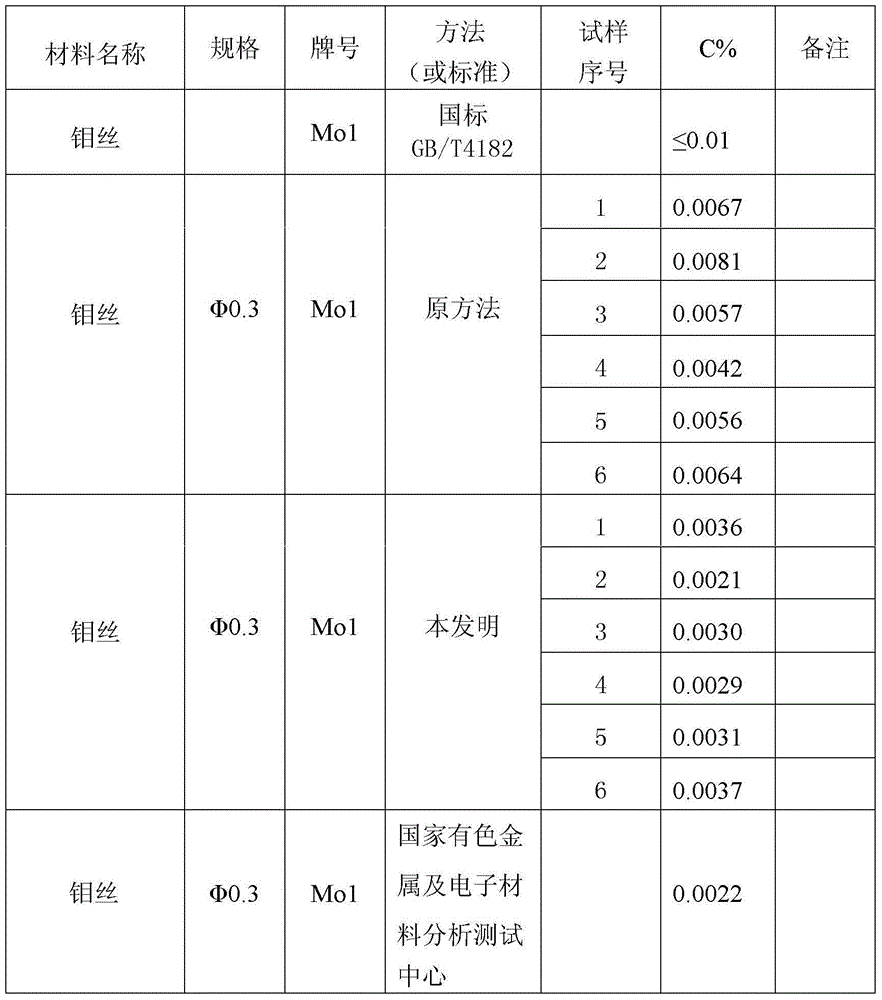

An analysis method and carbon element technology, which are applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of large deviation and low accuracy of analysis results, and achieve improved accuracy, good release, and reduced deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: a kind of Mo of the present embodiment The analysis method of carbon element in pure molybdenum is to carry out according to the following steps:

[0014] Step 1: Connect the carbon-sulfur analyzer for analyzing carbon by infrared absorption method to the power supply, and preheat for 2 to 4 hours;

[0015] Step 2: Burn the infrared ultra-low carbon sulfur crucible at 1000-1500°C for 20-30 minutes;

[0016] Step 3: Cool the crucible burned in Step 2 in a desiccator for 1 to 3 hours;

[0017] Step 4: After the preheating of the carbon-sulfur analyzer in step 1, weigh 0.2-0.5g of shavings Mo1 pure molybdenum, input the weight value, add 0.3-0.6g of iron filings and 0.3-0.6g of tungsten-tin flux ;

[0018] Step five: measure according to the analysis method of the instrument, and obtain the analysis result, that is, complete the analysis of the carbon element in Mo1 pure molybdenum.

[0019] This embodiment includes the following beneficial effe...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: preheating in step 1 for 3 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, the infrared ultra-low carbon sulfur crucible is burned at 1200-1500° C. for 25-30 minutes. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com