Automatic turnover type hot air infrared fruit and vegetable drying device and method

A drying device and hot air technology, applied in the direction of dehydration preservation of fruits/vegetables, food processing, etc., can solve the problems of increased labor intensity of workers, inability to dry fruits and vegetables, poor drying effect, etc., to shorten drying time, facilitate transportation, and reduce drying The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

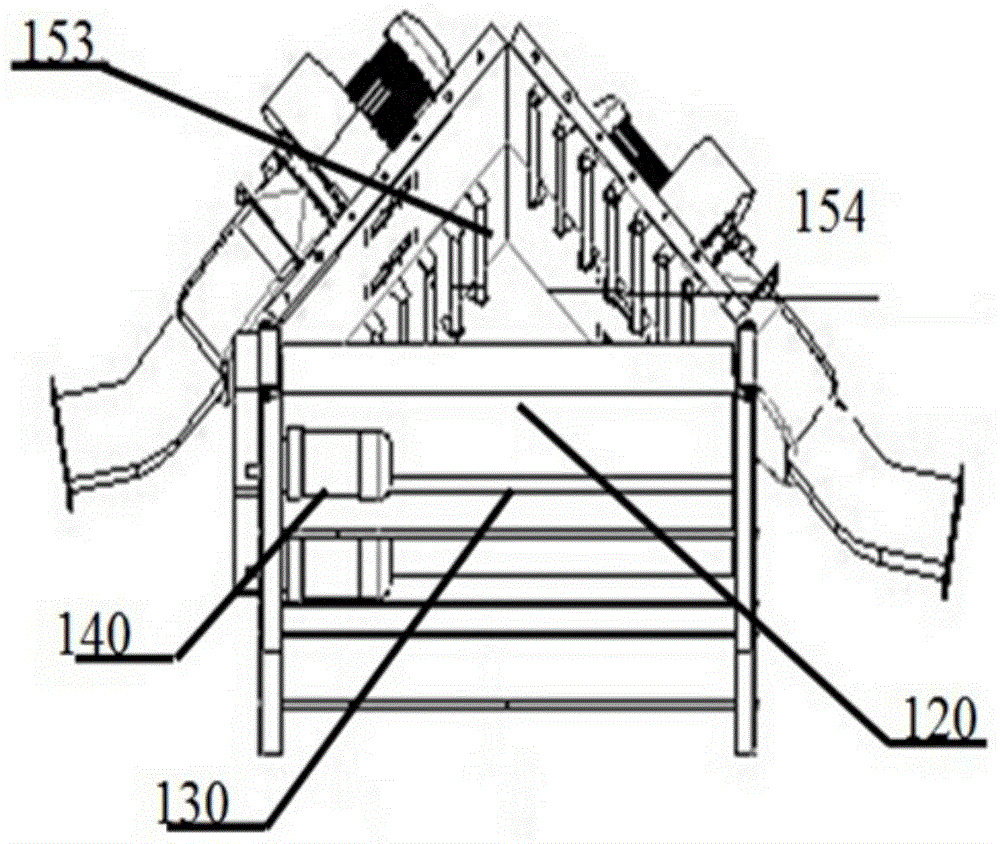

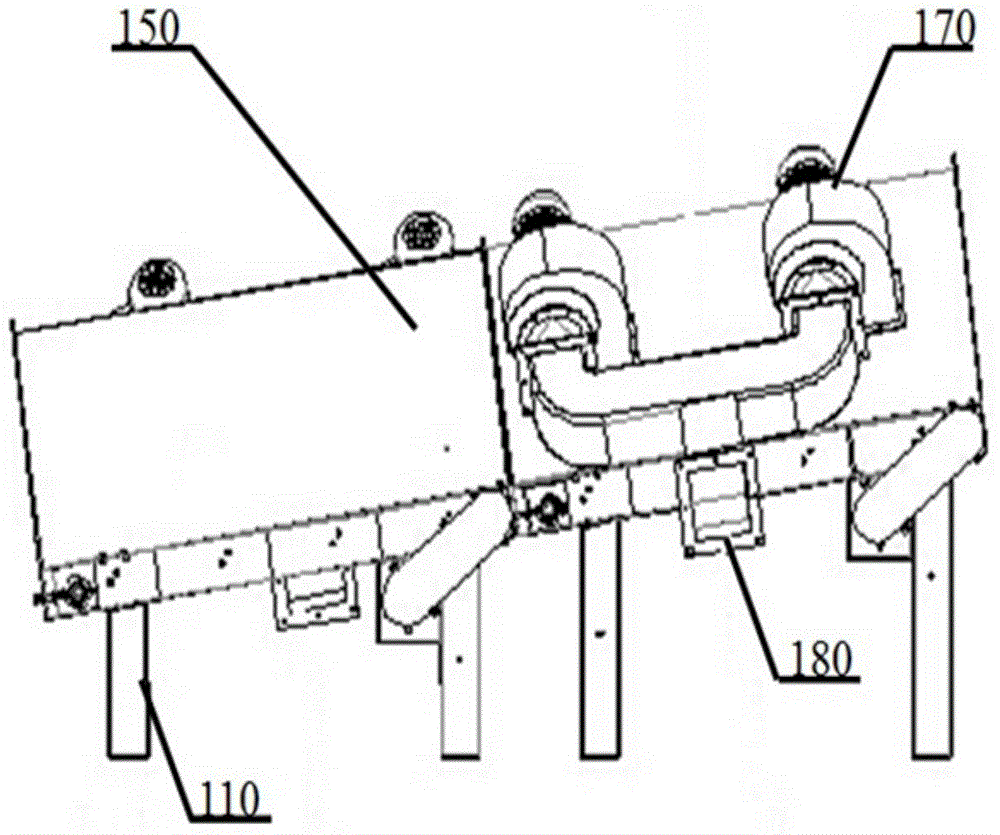

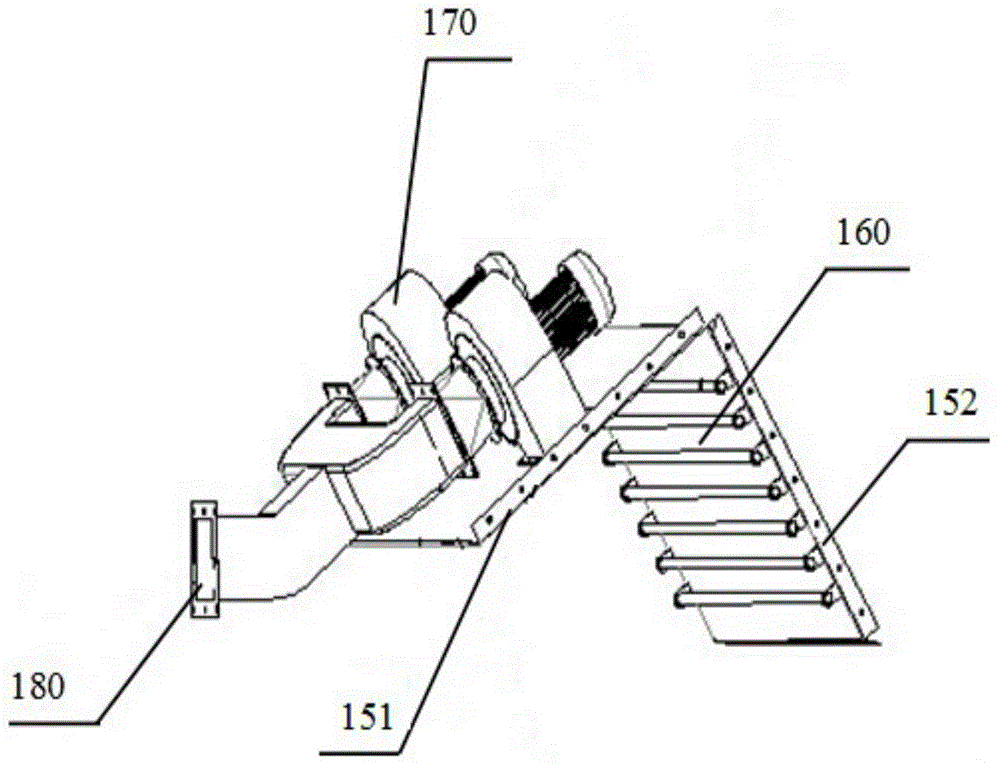

[0032] Such as figure 1 and figure 2 As shown, the first drying section of the automatic tumbling hot air infrared fruit and vegetable drying device provided by the present invention includes a support 110, a conveyor belt 120, a frame 130, a power motor 140, a drying chamber upper cover 150, an infrared heating tube 160, a fan 170 and an inlet. Air outlet 180.

[0033] The bracket 110, which is arranged at the lowest end, supports the entire drying device and includes a plurality of support columns;

[0034] Conveyor belt 120, its structural diagram is as Figure 4 As shown, it includes the feed side 121 and the end side 122, which work under the drive of the power motor 140 for conveying materials, and include a frame 130, which is mainly used for carrying the conveyor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com