InFocus-MIG/MAG electric-arc composite welding method

An infocus-mig, hybrid welding technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of high laser cost, achieve the effect of simple replacement of consumables, improve welding efficiency, and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

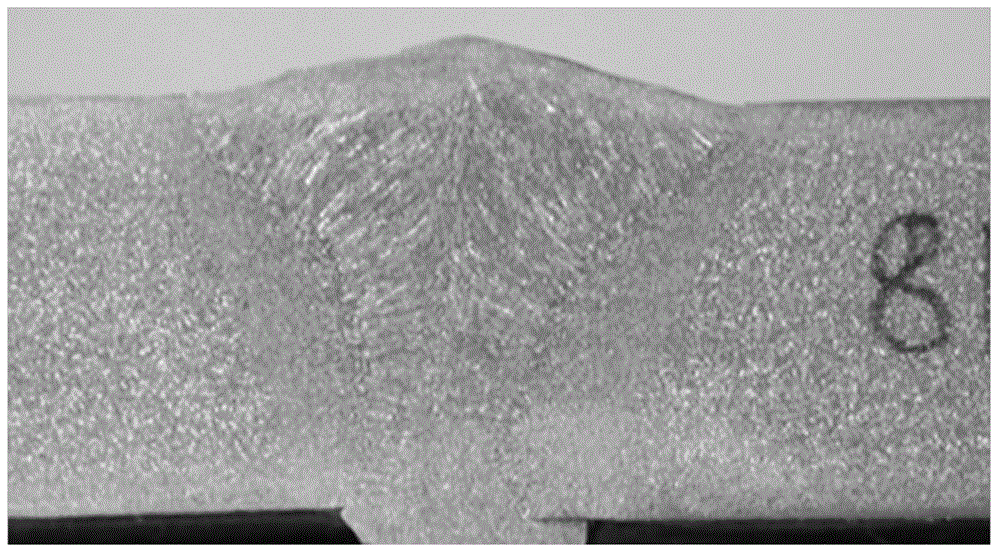

Examples

specific Embodiment approach 1

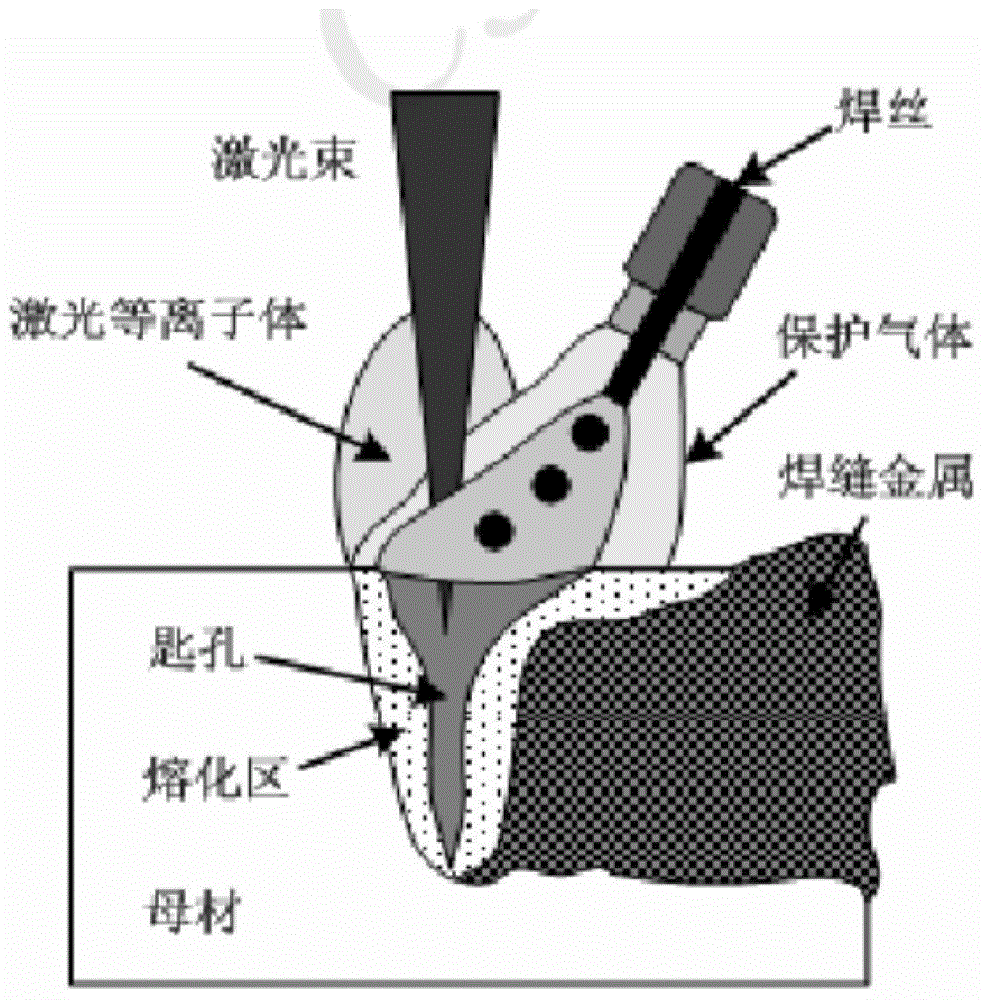

[0026] Specific embodiment one: a kind of InFocus-MIG / MAG electric arc hybrid welding method of the present embodiment, it is carried out according to the following steps:

[0027] Step 1: Before welding, grind or clean the surface of the workpiece to be welded, and fix the polished or cleaned workpiece to be welded on the welding fixture;

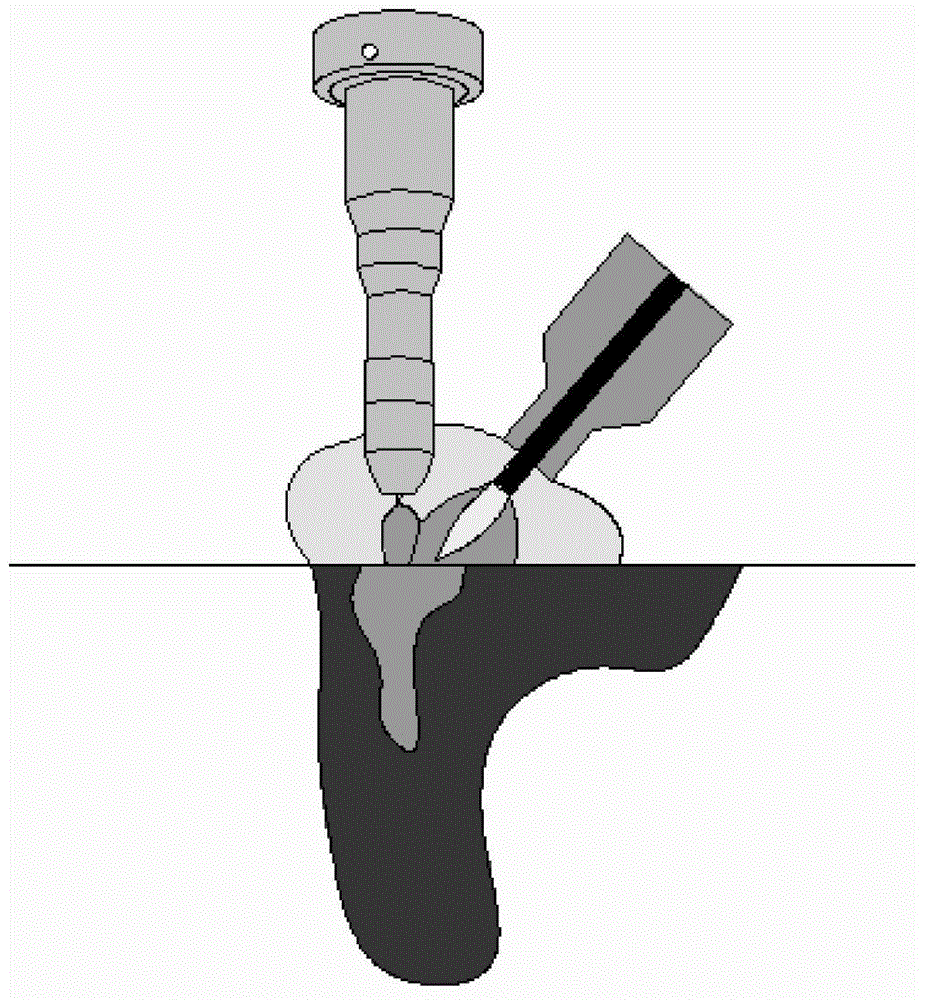

[0028] Step 2: Keep the axis of the InFocus welding torch vertical to the workpiece during the welding process, adjust the compounding of the MIG / MAG welding torch and the InFocus welding torch on the opposite side, and the angle between the MIG / MAG welding torch and the workpiece is 30-60°;

[0029] Step 3: Set welding process parameters: InFocus current is 800A, MIG / MAG welding current is 100-350A, MIG / MAG welding wire length is 10-15mm, shielding gas flow is 15-30L / min, InFocus cathode and MIG / MAG The distance between the light wires is 2-3mm, and the welding speed is 100-1000mm / min;

[0030] Step 4: Start the control switch, and carry...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that: during the welding process, the InFocus welding torch and the MIG welding torch work together on the molten pool area to be welded. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the angle between the MIG welding torch and the workpiece is 50°. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com