A Synchronous Orientation Grabbing Method of Laser Pulse Signal

A laser pulse and signal synchronization technology, which is applied in the laser field, can solve the problems of no laser pulse synchronous screening, the speed of the galvanometer cannot reach a wide spacing, etc., and achieve the effect of convenient and simple control and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

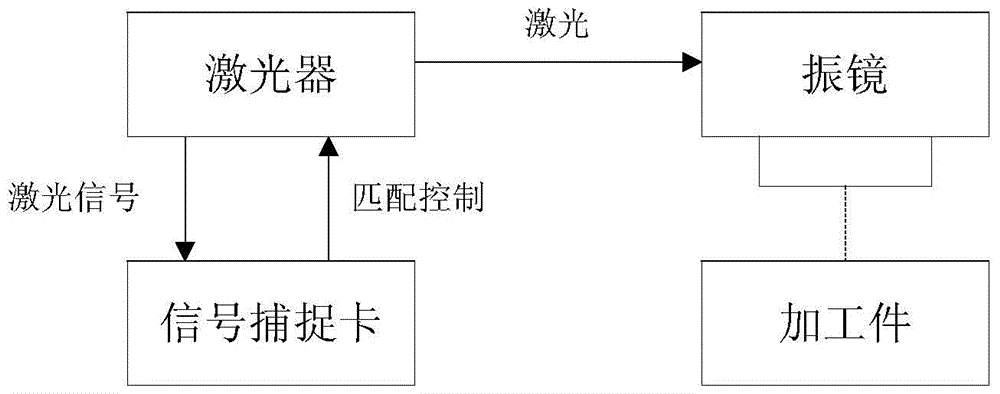

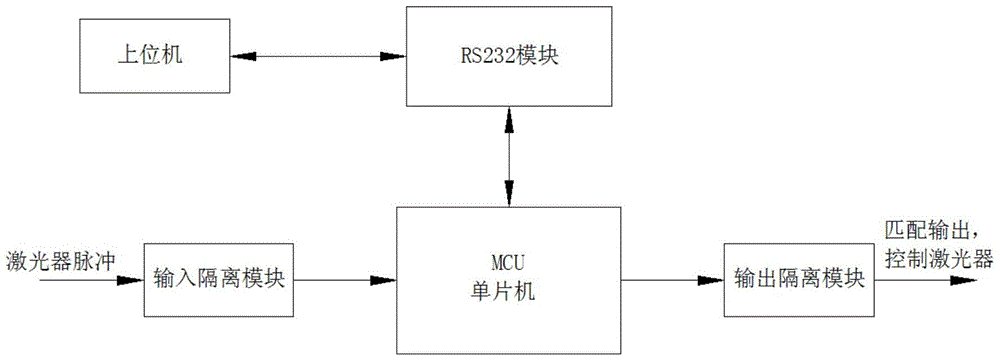

[0019] The present invention will be further described below in conjunction with accompanying drawing, as figure 1 , 2 , shown in 3, the core part of the present invention is a laser signal capture card, which synchronously processes laser pulse signals. This card is based on the MCU (single-chip microcomputer) controller, and is equipped with input signal isolation, output signal isolation and strengthening unit, and RS232 communication channel and so on. The specific workflow is as follows:

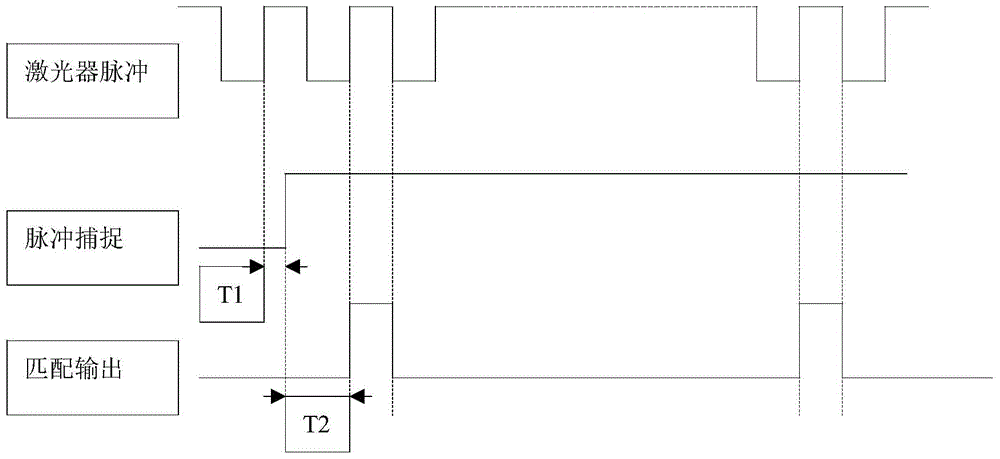

[0020] (1) The laser pulse signal is input to the MCU (single chip microcomputer) through the input isolation module, and the MCU captures the rising edge of the signal and calculates the frequency of the signal. Since the capture takes a certain amount of time, there is a time deviation T1 between the actual pulse phase and the captured phase.

[0021] (2) The MCU decides to match the frequency and duty cycle of the output pulse according to the parameters that have been set. As men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com