Complex surface on-machine test method of five-axis machining center

A five-axis machining center, complex profile technology, used in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the impact, such as lighting conditions, surface state reflection conditions, shadows, light blocking, errors, etc. , to reduce the scrap rate of workpieces, improve production efficiency, and reduce time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

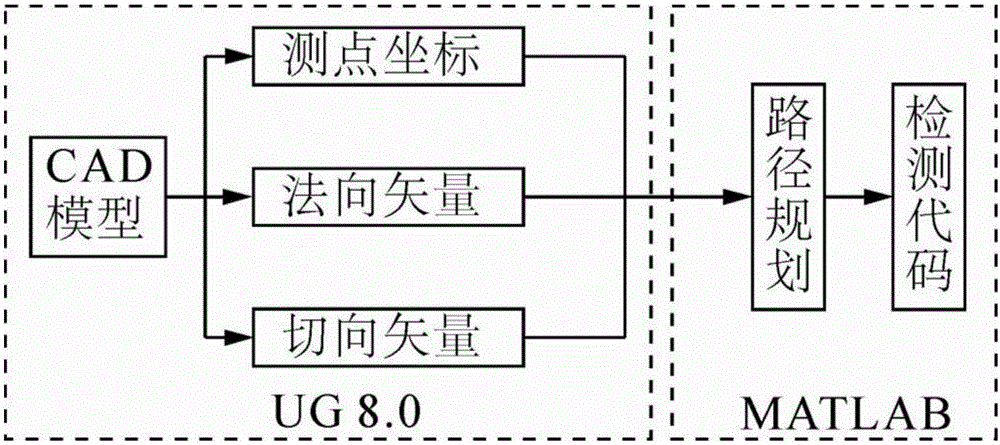

[0034] A method for on-machine detection of complex profiles of a five-axis machining center, see figure 1 , the method for on-machine detection of complex profiles includes the following steps:

[0035] 101: Based on the solid modeling technology of the commercial software UG NX8.0, plan the detection points, and obtain the coordinates, normal vectors and tangential vectors of the surface detection points;

[0036] 102: Use commercial visual mathematics software to read the coordinates, normal vector and tangential vector of the detection point, and plan the detection path;

[0037] 103: Detect the surface through the detection path, and generate the corresponding on-machine detection code according to the type of the five-axis machining center.

[0038] Wherein, in step 101, based on the solid modeling technology of the commercial software UG NX8.0, the detection points are planned, and the steps of obtaining the coordinates, normal vectors and tangential vectors of the sur...

Embodiment 2

[0046] This embodiment describes in detail the scheme in Embodiment 1 in conjunction with specific calculation formulas, examples, tests and accompanying drawings, see the following description for details:

[0047] 201: Based on the solid modeling technology of the commercial software UG NX8.0, plan the detection points, obtain the coordinates, normal vectors and tangential vectors of the surface detection points, and save them in the form of TXT files;

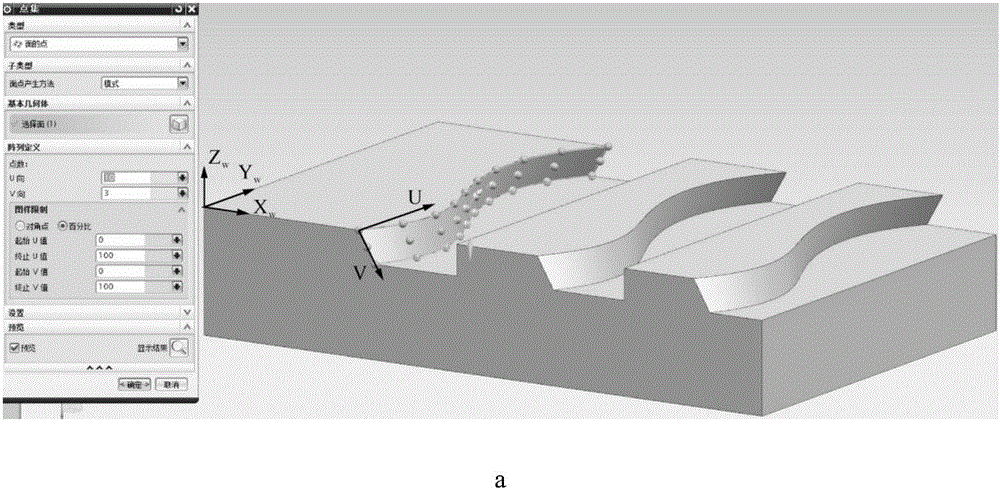

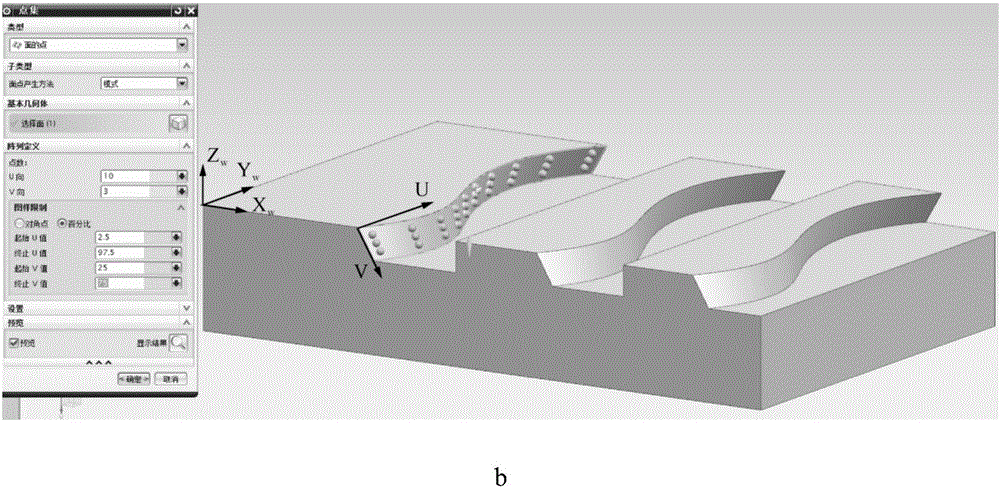

[0048] Wherein, the present invention is based on the point set function of commercial software UG NX8.0, in workpiece coordinate system (X w , Y w ,Z w ), select the detection surface, set the number of detection points according to the direction of the wire and the busbar of the NURBS (Non-Uniform Rational B-spline) surface, that is, the u and v directions, and create a group of detection points corresponding to the detection surface, such as figure 2As shown in a (including 10 columns, each column has 3 detection point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com