Automatic quantification supply control system

A control system and feeding technology, applied in the field of automatic quantitative feeding control system, can solve the problems of increased production cost, low labor efficiency, and multi-energy consumption, so as to reduce the loss of raw materials, improve product quality, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to more clearly illustrate the structural features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described below in conjunction with the drawings and specific embodiments:

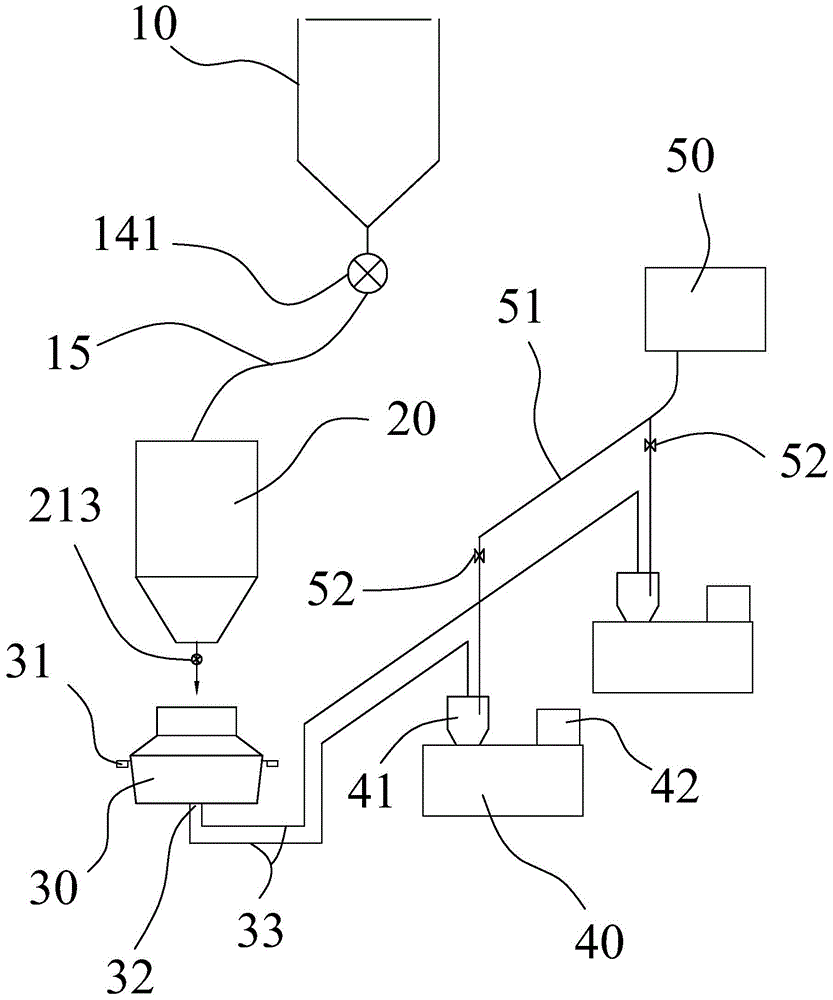

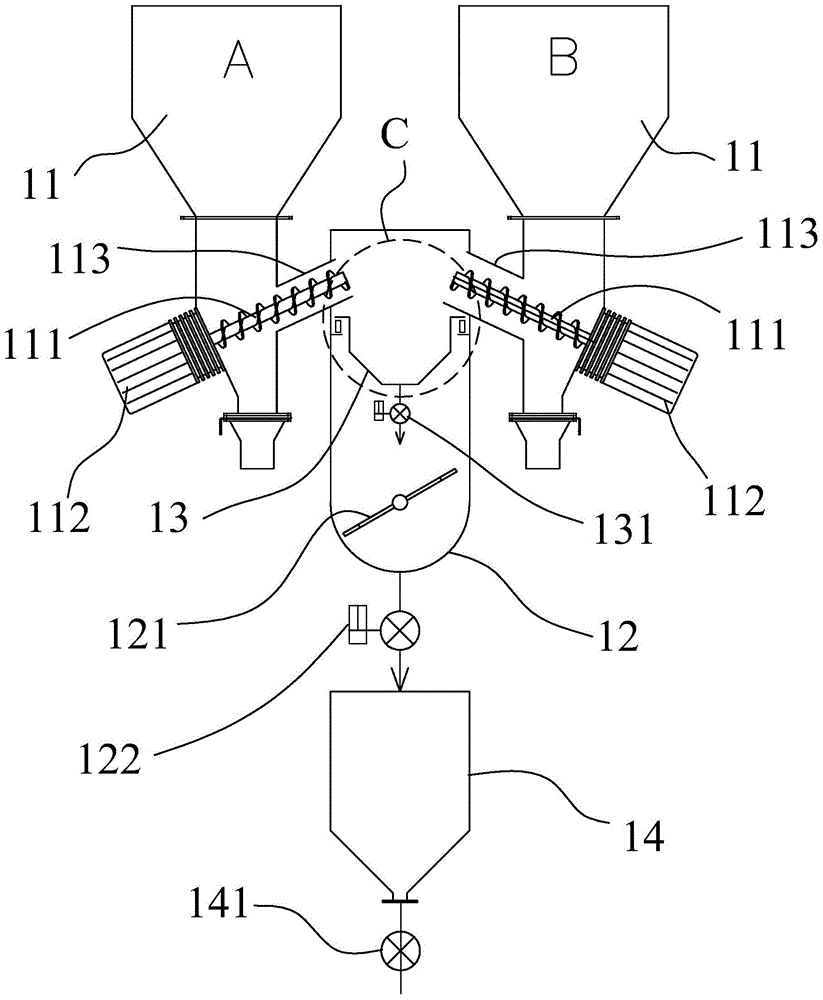

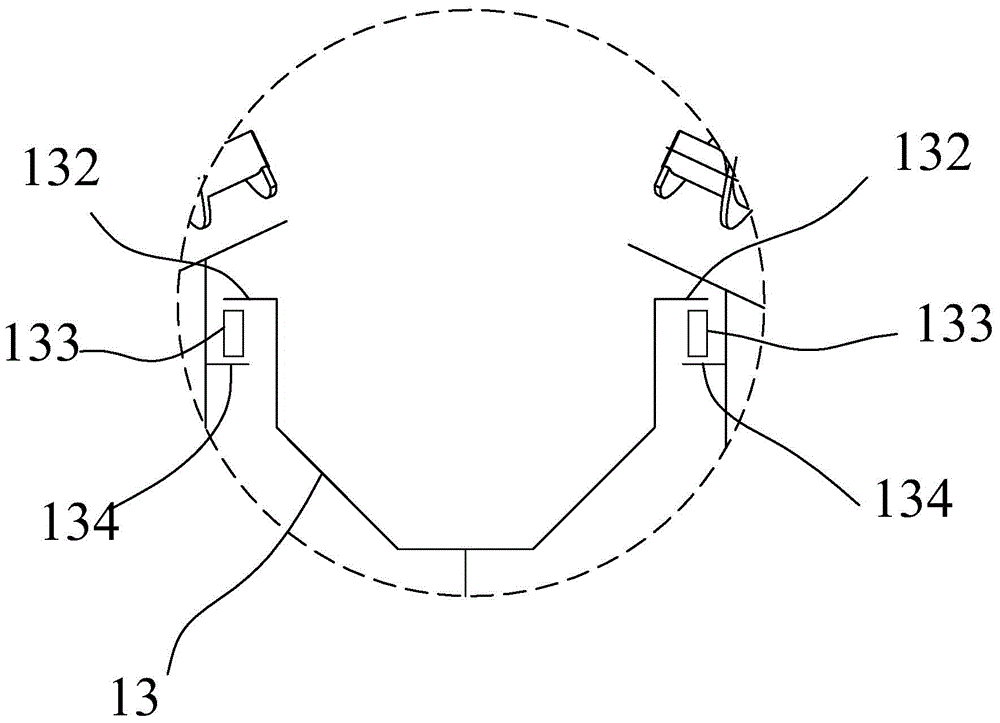

[0040] First, please refer to figure 1 As shown, an automatic quantitative feeding control system includes a quantitative feeding host unit, a negative pressure air pipe 51 connected with vacuum hoppers 41 of a plurality of injection molding machines 40, and a distribution pipe 33. The quantitative feeding host unit It includes a weighing ratio mixer 10, a dryer 20, a weighing bucket 30 and a main control panel.

[0041] The weighing ratio mixer 10 is connected to the dryer 20 through a main feeding pipe 15. The lower end of the weighing ratio mixer 10 is provided with a feeding valve 141 communicating with the main feeding pipe 15, and the dryer 20 is located at the weighing station. Above the heavy material barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com