Preparation method of liquid fermentum rubrum for brewing

A red yeast rice and liquid technology, applied in the field of producing a liquid red yeast rice for brewing, can solve the problems of weak saccharification power, high acidity, low production efficiency, etc., and achieve the effects of high alcohol content and low acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

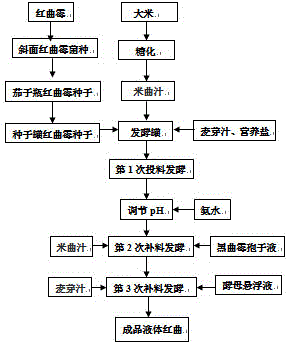

Method used

Image

Examples

Embodiment 1

[0076] 1. The first feeding and fermentation

[0077] (1) Feeding: Proportion according to the following components by weight:

[0078] 12 。 Bx Wort 20L

[0079] 14 。 Bx Rice Koji Juice 30L

[0080] Monascus liquid seeds 50L

[0081] water 900L

[0082] Nutrient salt 5 kg;

[0083] Wherein the nutrient salt ratio is:

[0086] Potassium dihydrogen phosphate 2 kg

[0087] Add the above-mentioned components into a fermentation tank with a total volume of 30kL, and the volume of the fermented mash fed for the first time is 8kL.

[0088] (2) Fermentation process conditions:

[0089] For the first 8 hours, the fermentation culture temperature was 33°C, and sterile air was introduced, and the ventilation rate was 0.5L of sterile air per liter of feeding amount per minute; after 8 hours, the fermentation culture temperature was 35°C, and sterile air was introduced, and the ventilation rate was Inject 1.0L of steri...

Embodiment 2

[0106] 1. The first feeding and fermentation

[0107] (1) Feeding: Proportion according to the volume of the following components:

[0108] 12 。 Bx Wort 20L

[0109] 14 。 Bx Rice Koji Juice 20L

[0110] Monascus liquid seeds 60L

[0111] water 900 liters

[0112] Nutrient salt 5 kg;

[0113] Wherein the nutrient salt ratio is:

[0116] Potassium dihydrogen phosphate 2 kg

[0117] The above-mentioned components were added into a fermentation tank with a total volume of 60 kL and mixed evenly, and the volume of the fermented beer fed for the first time was 16 kL.

[0118] (2) Fermentation process conditions:

[0119] For the first 8 hours, the fermentation culture temperature was 34°C, and sterile air was introduced, and the ventilation rate was 0.5L of sterile air per minute per liter of fermented mash in the tank; after 8 hours, the fermentation culture temperature was 36°C, and sterile air was introduced, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com