Retaining wall drain pipe reversed filter structure

A technology for drainage pipes and retaining walls, which is applied in sewer pipe systems, infrastructure engineering, filtration circuits, etc., can solve problems such as easy damage, difficulty in ensuring construction quality, difficulty in meeting mechanization, and rapid construction requirements, and achieves convenience in use, The effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

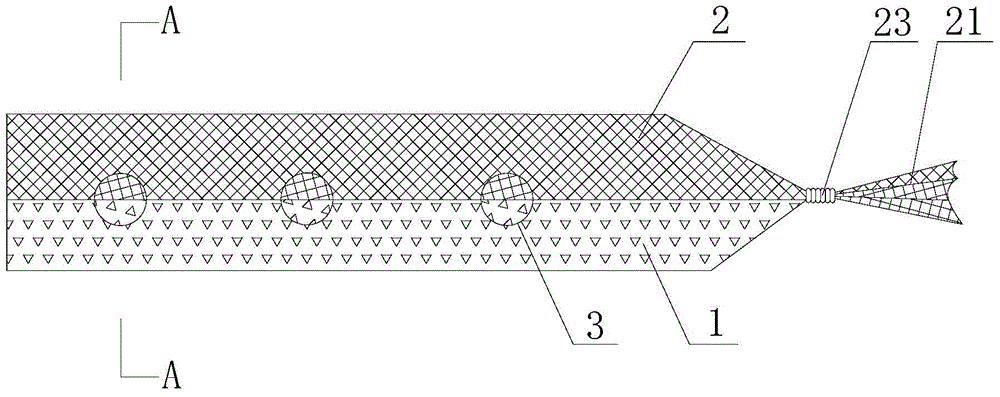

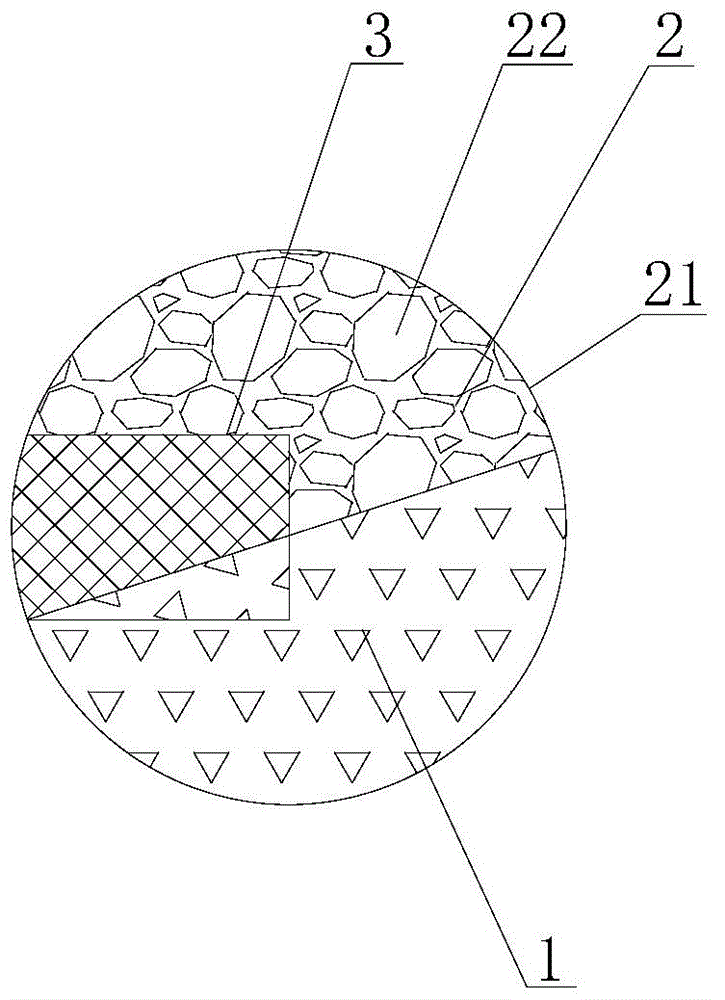

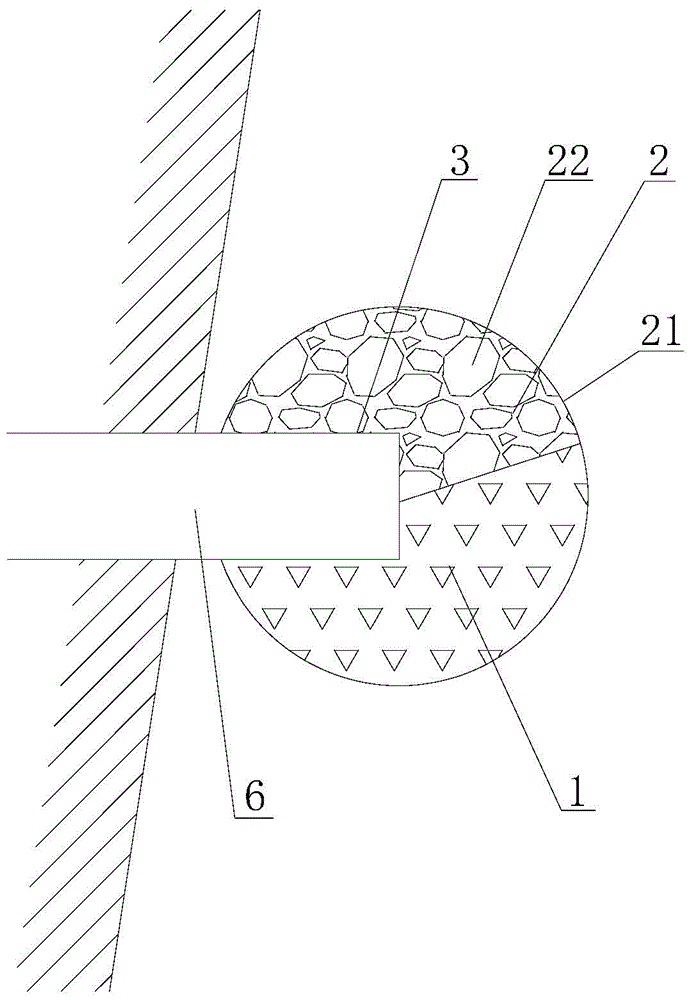

[0034] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a retaining wall drainage pipe anti-filtration structure, wherein the retaining wall drainage pipe anti-filtration structure includes a water collection part 1 and a filter part 2 fixed on the water collection part 1, and the filter part 2 is filled with The filter bag 21 of the filter material 22, the joint surface of the filter part 2 and the water collection part 1 is a slope, and at least one water supply and drainage pipe 6 is provided on the lower side of the corresponding slope between the filter part 2 and the water collection part 1. The guide blind hole 3, at least a part of the port of the insertion end of the drain pipe 6 is connected with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com