Deep-rhizome crop harvester

A technology for root crops and harvesters, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problem of the long distance between the soil conveyor and the chain excavation belt, cannot ensure that the yam is exposed to the soil surface, and increase the harvest. Machine forward resistance and other issues, to achieve the effect of improving cutting efficiency, good digging quality, and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

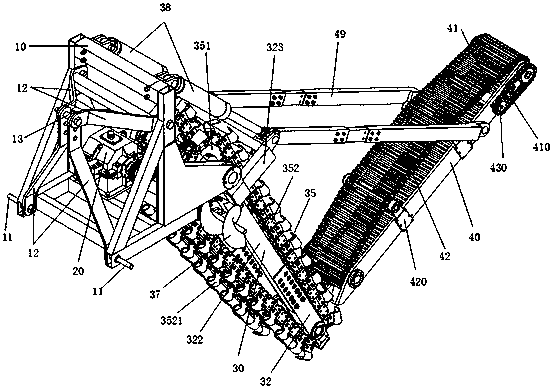

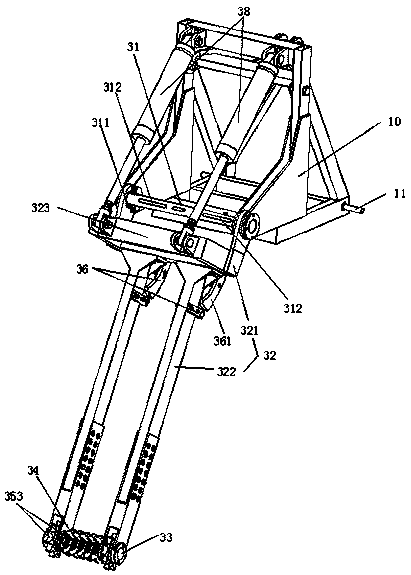

[0045] see figure 1 and Figure 5 , a deep root crop harvester, including a frame 10 and a transmission device 20 located on the frame 10, a deep digging device 30, and a conveying device 40 for transmitting and wrapping crop soil to be harvested, and the transmission device 20 will The power of the tractor rear output shaft is transmitted to the main shaft 31 of the deep digging device 30; the deep digging device 30 also includes a support frame 32, a driven shaft 33, at least one soil ridge cutting mechanism 34 and at least two trenching mechanisms 35 ( In this embodiment, two trenching mechanisms 35 and a soil ridge cutting mechanism 34 are taken as examples), the near frame end of the support frame 32 is provided with the main shaft 31, and the near frame end is rotatably connected with the frame 10, the The far frame end of the support frame 32 is provided with the driven shaft 33, and the far frame end is connected to the conveying device 40, and the soil ridge cutting...

Embodiment 2

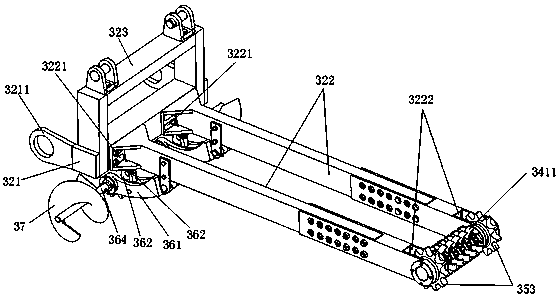

[0052] In this embodiment, a soil discharge mechanism is added to the technical solution of the first embodiment to prevent the excavated soil from slipping into the ditch and affecting the advancement of the conveying device 40 . Simultaneously, a first tensioning mechanism 36 is added in conjunction with the earth-discharging mechanism to keep the ditching chain 352 in a tensioned state.

[0053] see Figure 3-1 , Figure 3-2 as well as figure 1 , the deep digging device 30 also includes at least two first tensioning mechanisms 36, which are arranged in one-to-one correspondence with the trenching mechanism 35; the first tensioning mechanism 36 is fixed below the support frame 32; the The first tensioning mechanism 36 includes a tensioning bracket 361, a tensioning sprocket 362 and an adjusting nut 363, one end of the tensioning bracket 361 is hinged to the support frame 32, and the other end is provided with the tensioning sprocket 362, the tensioning sprocket 362 is fi...

Embodiment 3

[0057] This embodiment can be combined with embodiment one and / or embodiment two to form a new technical solution, so that the harvester has increased the following functions: the angle between the ditching chain 352 and the ground in the deep digging device 30 can be adjusted by the hydraulic support 38 Adjustment, the depth of the ditch can be changed by adjusting the length of the telescopic arm 322, and the width of the ditch can also be adjusted.

[0058] see figure 2 and Figure 3-1 , the two ends of the main shaft 31 are provided with bearing sleeves 311, the bearing sleeves 311 are fixed on the frame 10, and the near frame end of the support frame 32 is provided with two earrings 3211, and the earrings 3211 are set on the On the outer wall of the bearing sleeve 311; a hydraulic support 38 is also hinged between the support frame 32 and the frame 10. In this embodiment, a hinge support 323 is arranged above the support frame 32, and the hydraulic support One end of 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com