Elastic support structure

A technology of elastic support and support surface, applied in the direction of springs/shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of low sustained performance of support structures, complex support structures, and low reliability, and increase structural damping. Effect, wide application environment, flexible form effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

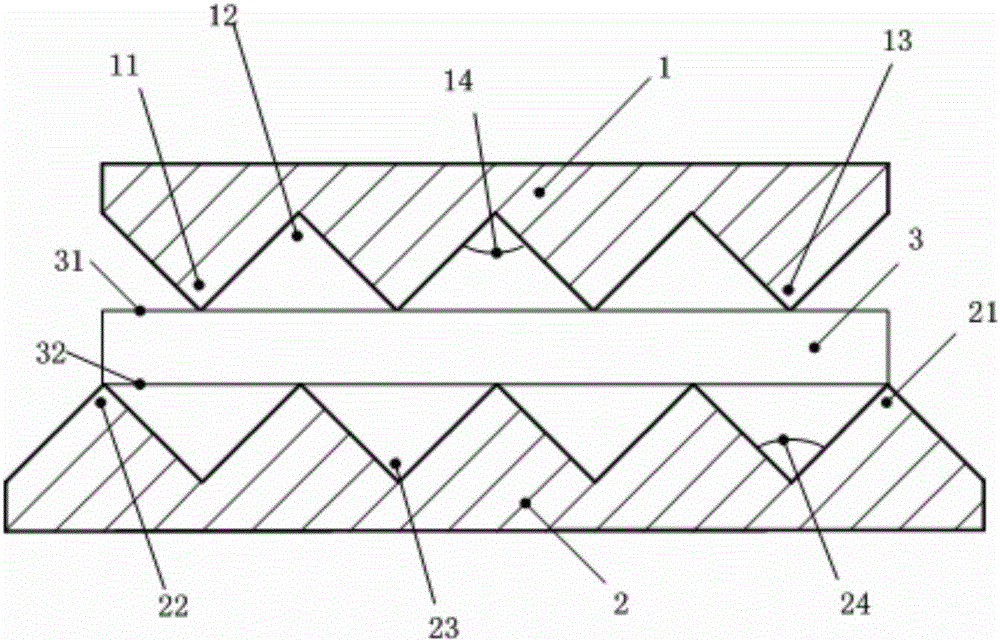

[0046] This embodiment provides an elastic support structure used in the rotor support system, the elastic support structure is used as a support system for the bearing 4, and the assembly relationship between the elastic support structure and the housing part 5 is as follows Figure 7 , the pressure bearing surface 1 of the elastic support structure is located outside the bearing 4, and the support surface 2 of the elastic support structure is located inside the shell member 5; the pressure bearing surface 1 contacts the upper surface 31 of the elastic layer through the end teeth 11 of the pressure bearing surface, and the assembly The relationship is a transition fit; the support surface 2 is in contact with the lower surface 32 of the elastic layer through the support surface end teeth 21, and the assembly relationship is a transition fit.

Embodiment 2

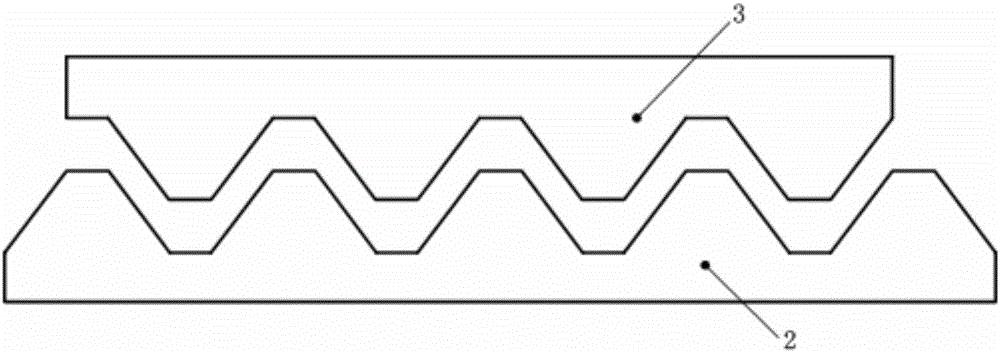

[0048] For the field of vehicle tires, such as Figure 8 , On the basis of the elastic support structure provided in Embodiment 1, it is advisable to set a closed cover 6 on the periphery to prevent debris from filling into the gap of the elastic support structure, thereby losing the functions of elastic support and vibration reduction. The pressure-bearing surface 1, the support surface 2, and the elastic layer 3 can all be made of rubber, and the rest of the technical features and rules are as described in the first embodiment. Utilizing the principle of the elastic support structure provided by the invention, the non-pneumatic tire structure can be realized by using the rubber material used in common tires. It not only ensures the driving performance, but also avoids the disadvantages of the inflatable structure.

[0049] Analysis shows that compared with the prior art, advantages and beneficial effects of the present invention are:

[0050] 1. The structure of the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com