An electromagnetic drying drum for a pulping machine

A technology of drying cylinder and sizing machine, which is applied in the field of sizing processing, which can solve the problems of product quality impact, scalded thread, tightness, etc., and achieve the effects of improving drying effect, preventing scalded thread, and increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

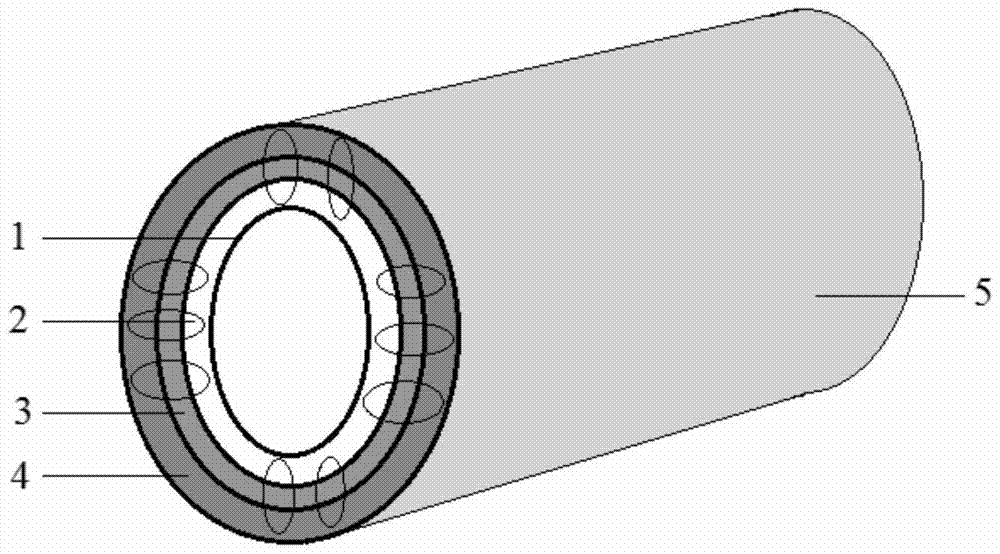

[0011] like figure 1 As shown, an electromagnetic drying drum for a pulp machine, which includes an annular electromagnetic coil 1, an annular ceramic ring 3 wrapped outside the electromagnetic coil 1, and an annular ceramic ring 3 coated on the ceramic ring 3, the circular iron ring 4, and the drying cylinder surface layer 5 covering the outer periphery of the iron ring 4. The outer diameter of the electromagnetic coil 1 is 60-63 cm, the thickness of the ceramic ring 3 is 5-7 cm, the thickness of the iron ring 4 is 5-7 cm, and the thickness of the surface layer 5 of the drying drum is 0.2-0.5 cm. cm. The electromagnetic coil 1 generates eddy current to make the iron ring 4 generate heat, and the ceramic ring 3 between the two can play a role of heat insulation.

[0012] The above-mentioned embodiments are only to illustrate the tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com