Patents

Literature

35results about How to "Intensified movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency and high-strength composite material with far infrared radiation heating and preparation method thereof

InactiveCN106317728AMetabolism and HealthEfficient and high-strength far-infrared radiant heating energyEnvironmental resistanceElectric heating

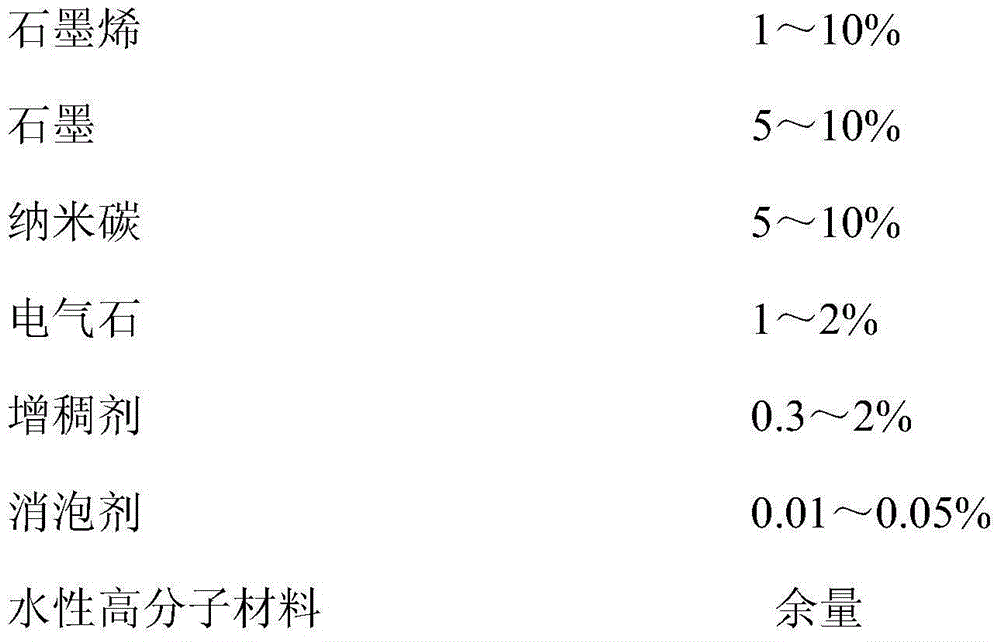

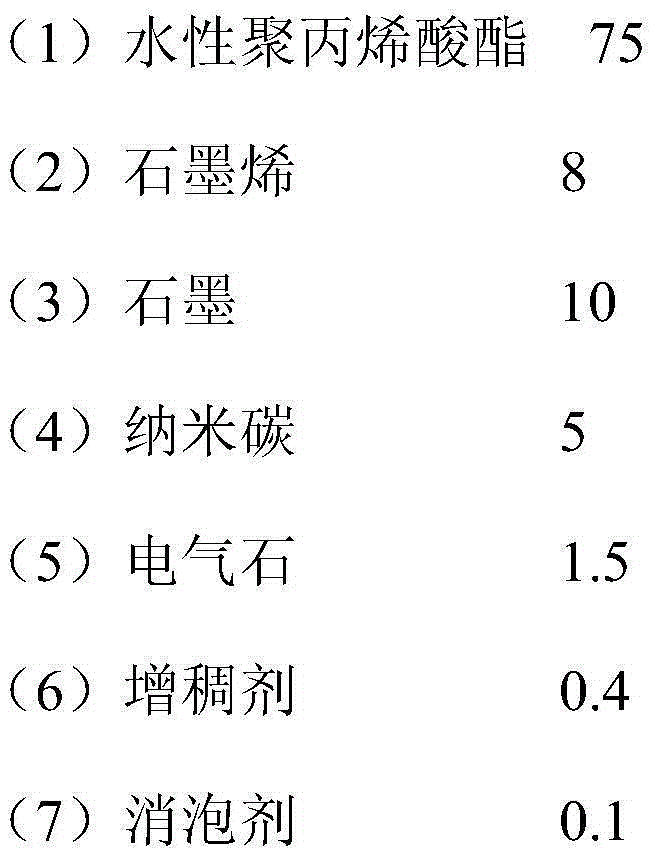

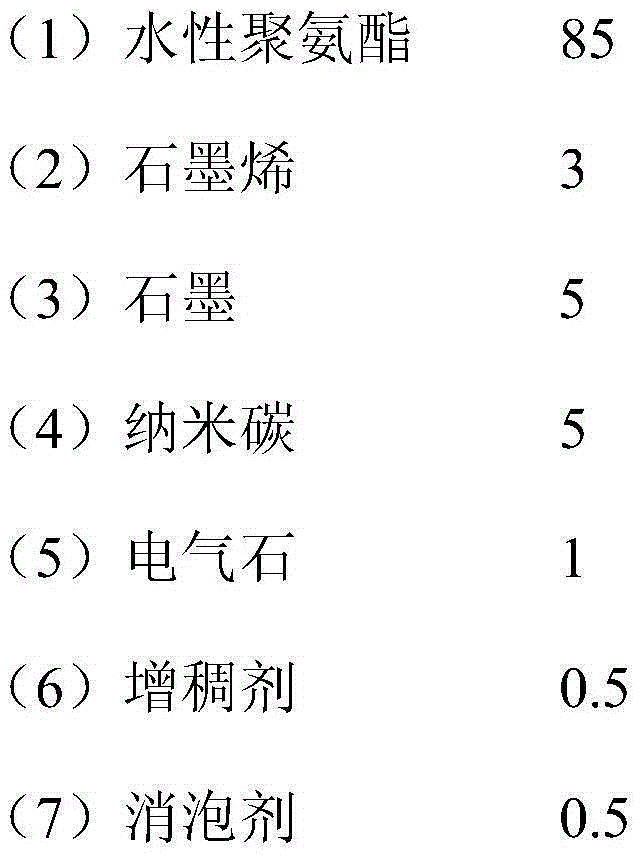

The invention relates to a high-efficiency and high-strength composite material with far infrared radiation heating. The material is characterized in that the material comprises the following raw materials in percentages by mass: 1-10% of graphene, 5-10% of graphite, 5-10% of nanocarbon, 1-2% of tourmalinite, 0.3-2% of a thickening agent, 0.01-0.05% of an antifoaming agent, and the balance being an aqueous high-molecular material. The far infrared composite material comprises graphene, graphite, nanocarbon, tourmalinite, and other powder materials with the far infrared radiation heating function. The material can be widely applied to electric heating, electric heating drying, health care, antibiosis, and other aspects. In addition, the composite material comprises the special tourmalinite material, in order to release a certain concentration of negative oxygen ions, and realize the purpose of air purification and environmental protection.

Owner:SHANGHAI WEIXING NOVEL BUILDING MATERIAL

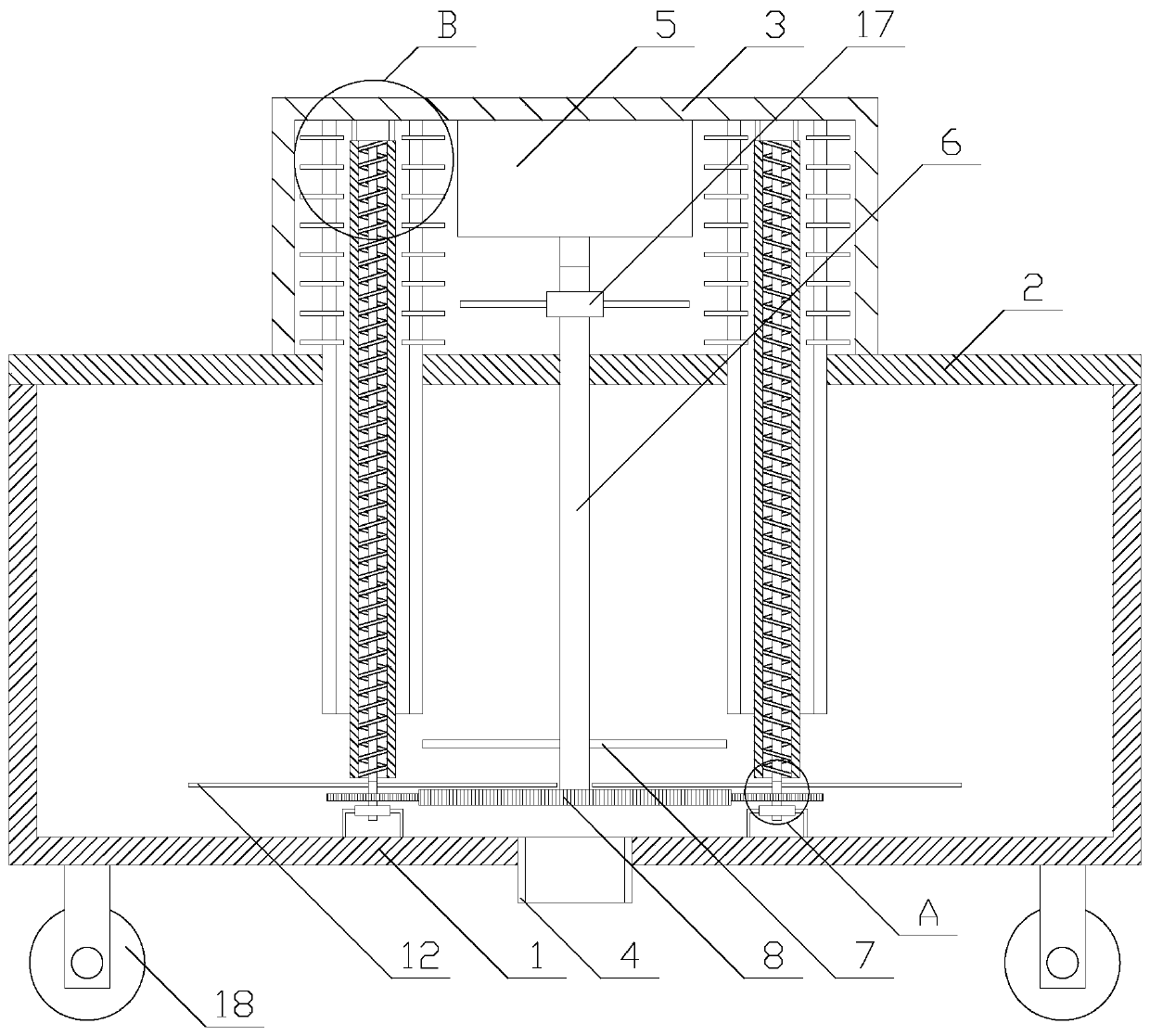

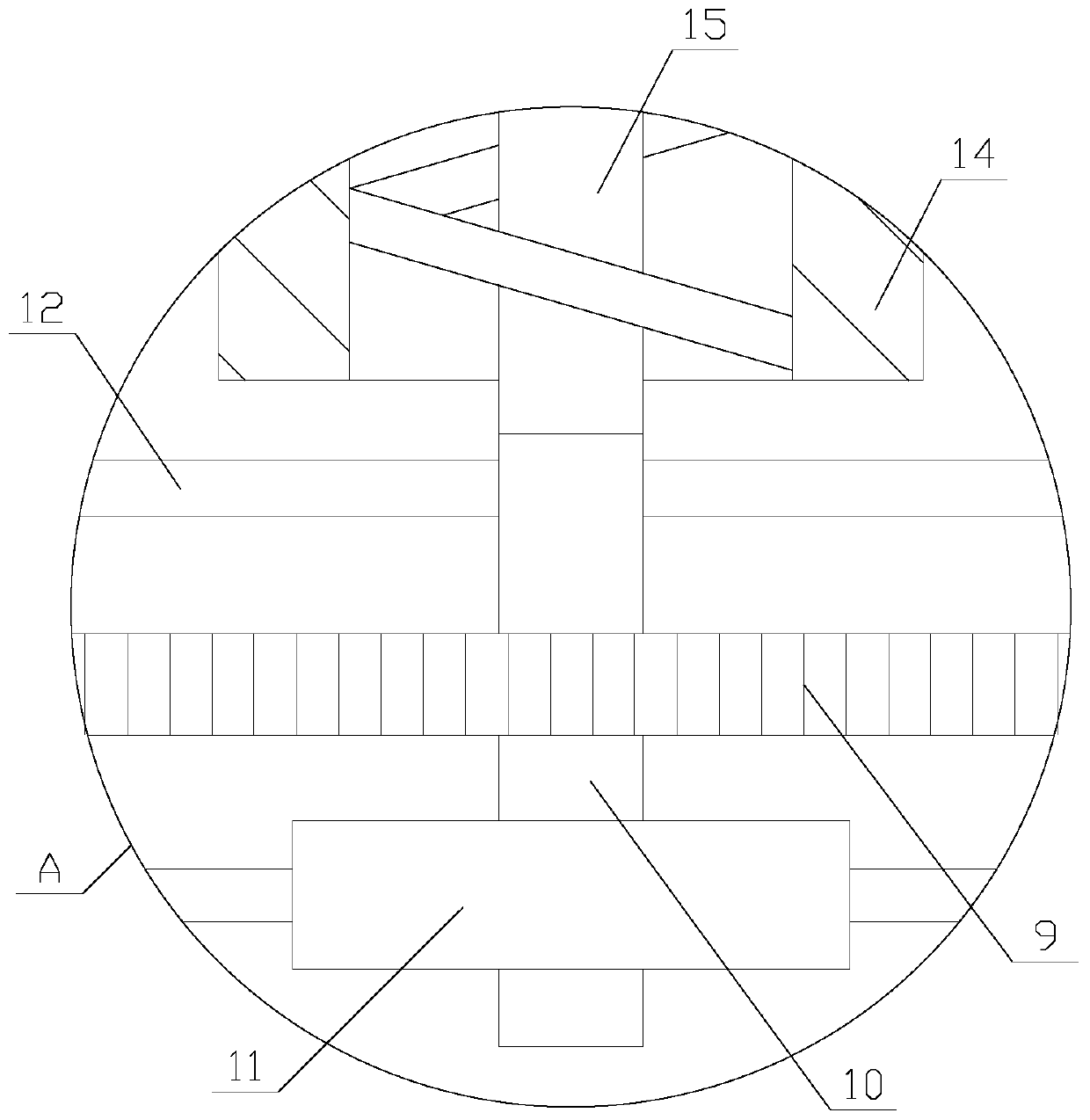

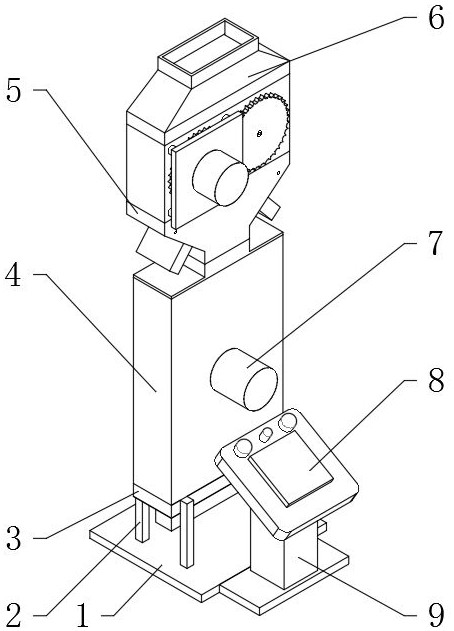

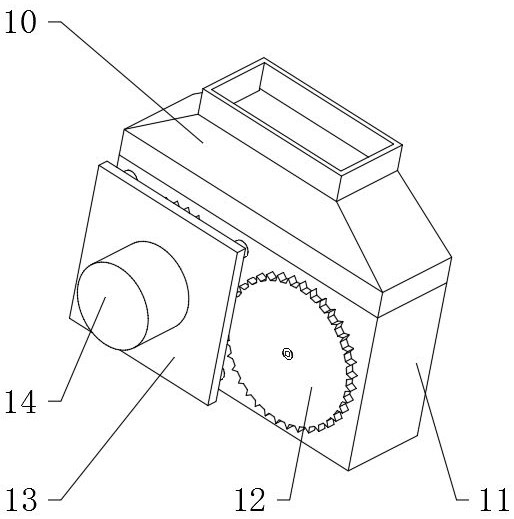

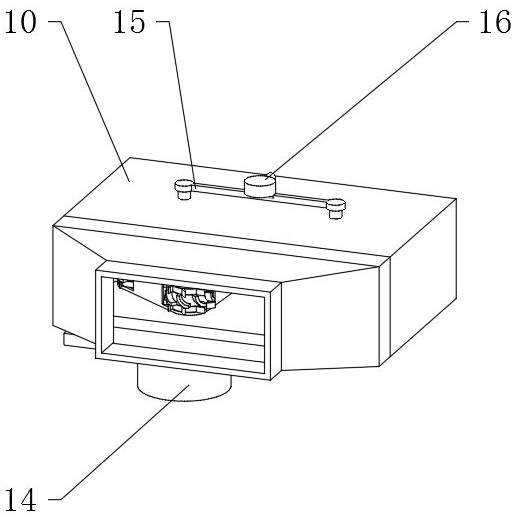

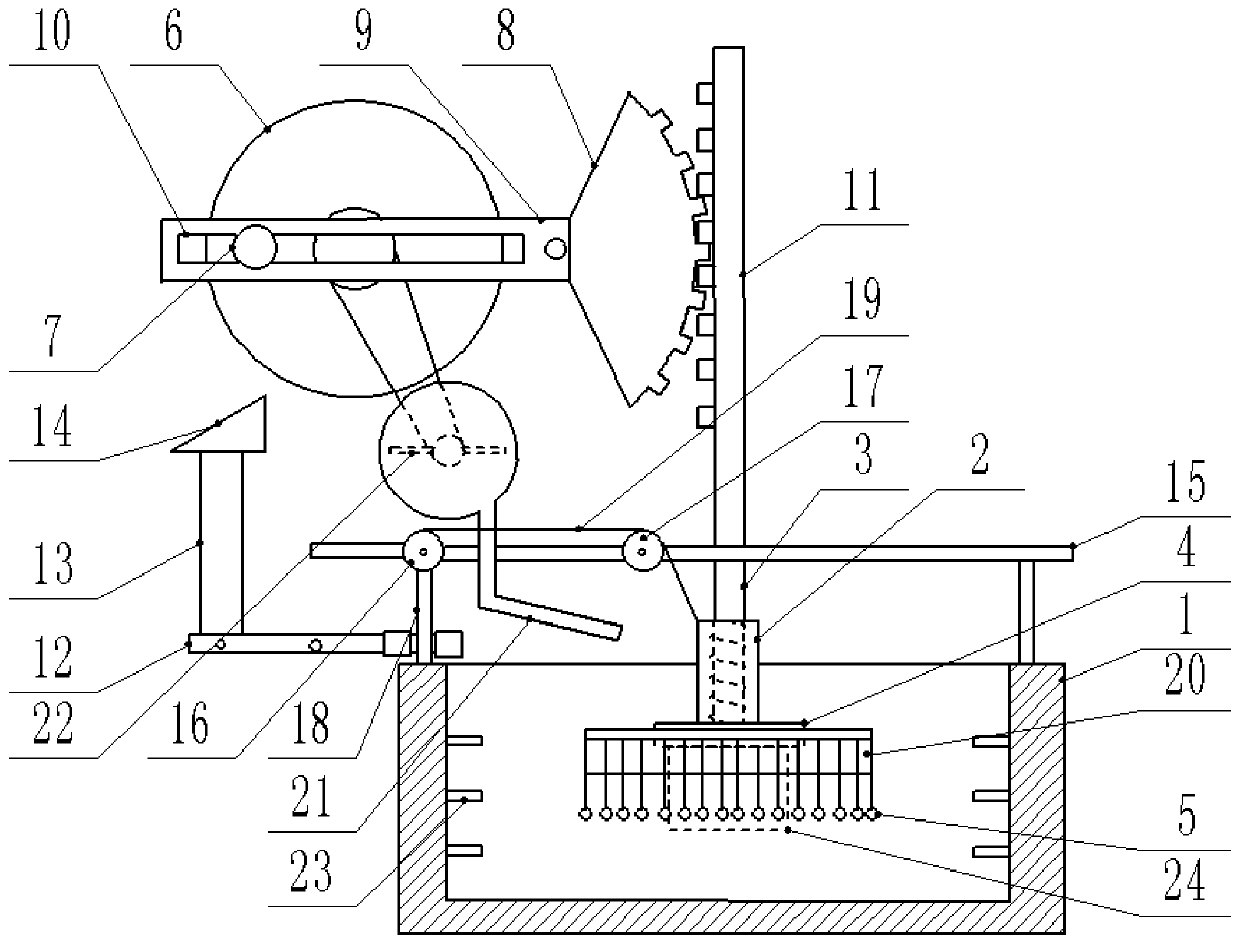

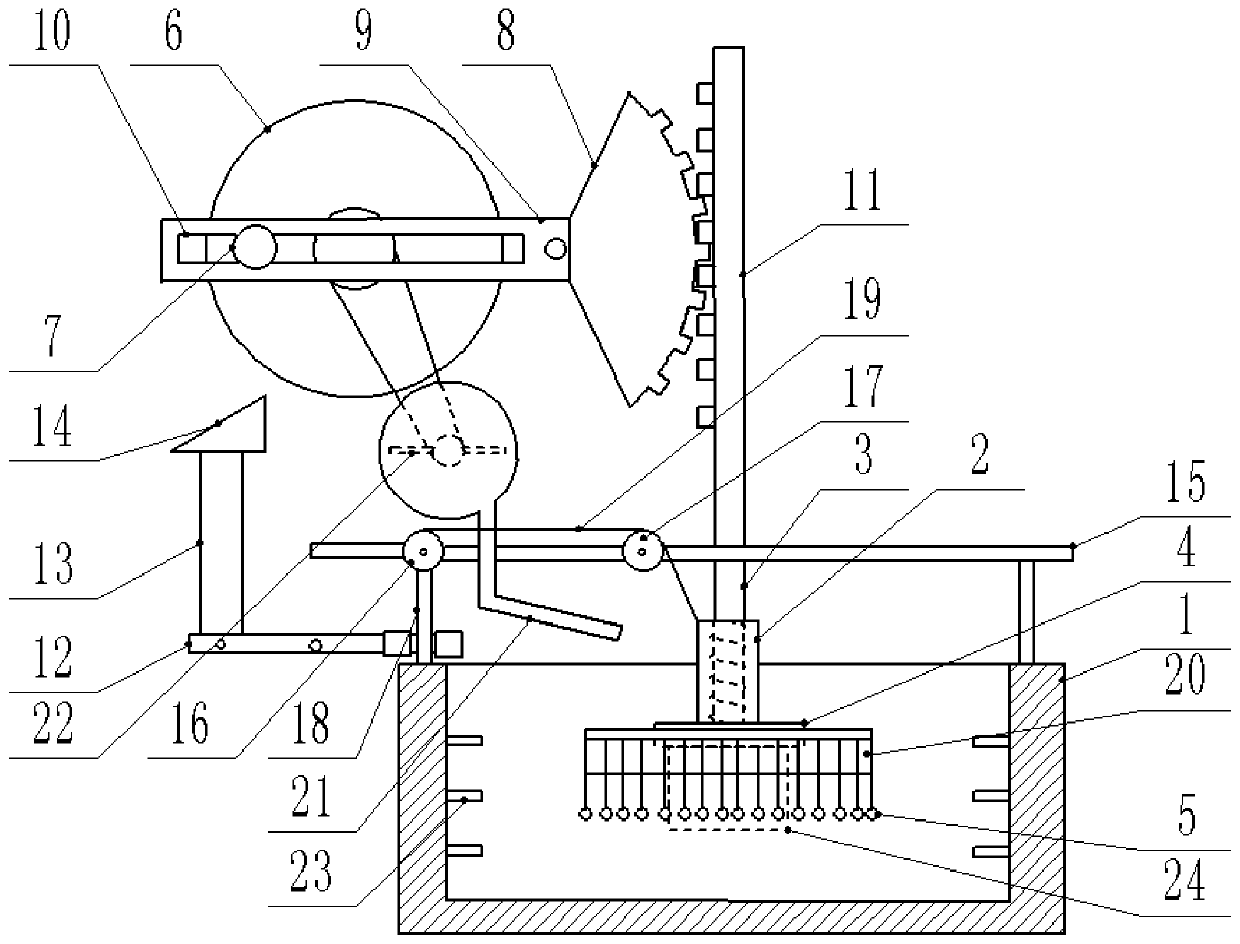

Device for processing gearbox parts

ActiveCN108554715AEasy to operateRealize automatic full paintingLiquid surface applicatorsCoatingsGear wheelReciprocating motion

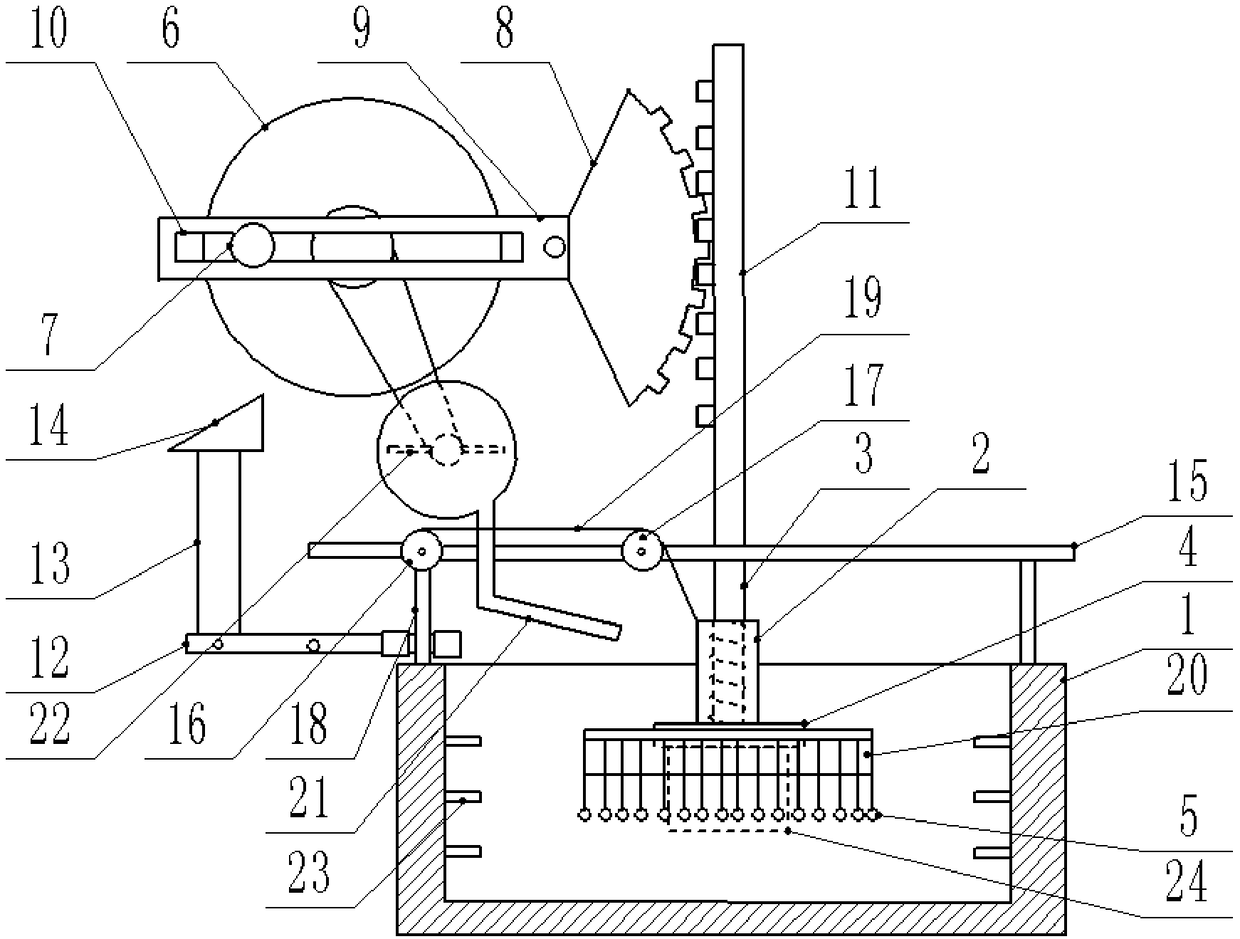

The invention relates to the field of production and processing of gears and discloses a device for processing gearbox parts. The device comprises a paint tank; a vertically arranged screw rod pair isarranged in the paint tank; the screw rod pair is rotatably connected with the tank wall of the paint tank; the lower end of the screw rod pair is connected with a fixing disk for fixing a gear; theround side part of the fixing disk is connected with a plurality of lifting ropes which are distributed uniformly; the lifting ropes are connected with lifting balls; screw rods matched with the screwrod pair penetrate through the screw rod pair; and the screw rods are connected with a reciprocating motion mechanism for controlling the screw rods to do straight reciprocating motions. The device can realize comprehensive and automatic painting of the gear and does not need hands to turn over.

Owner:重庆市大足区川江金属制品厂

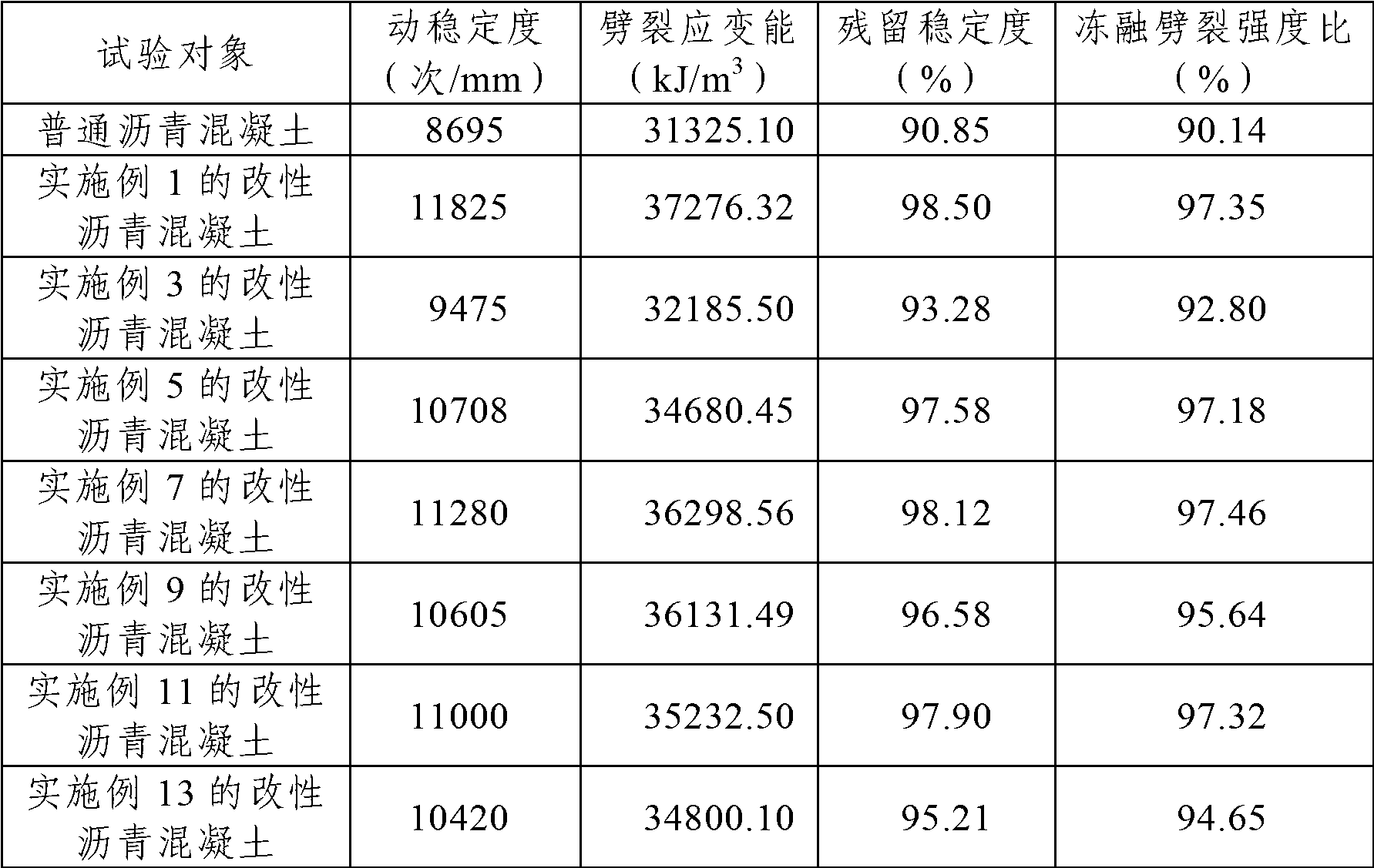

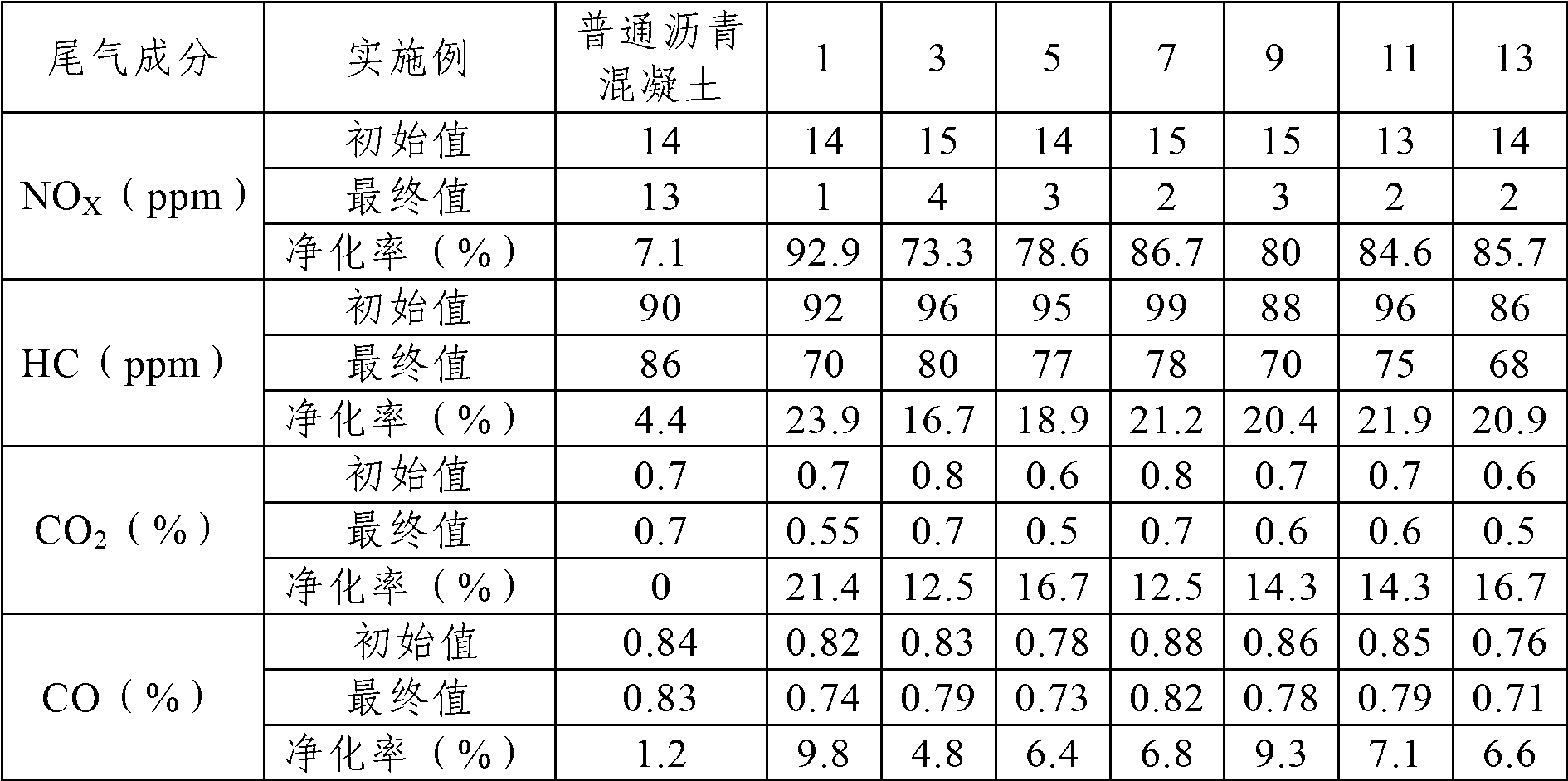

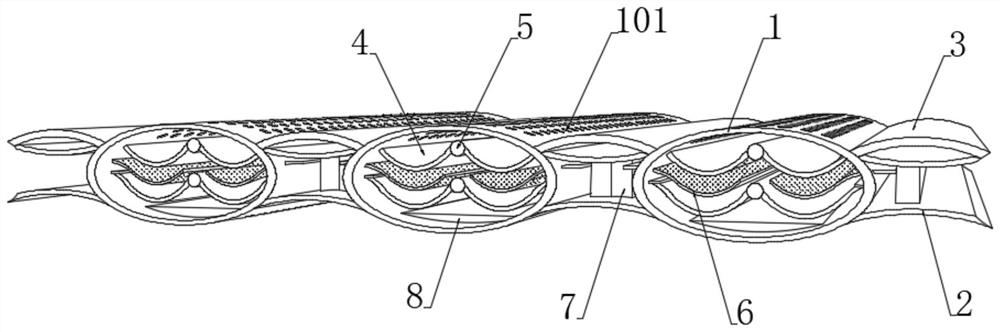

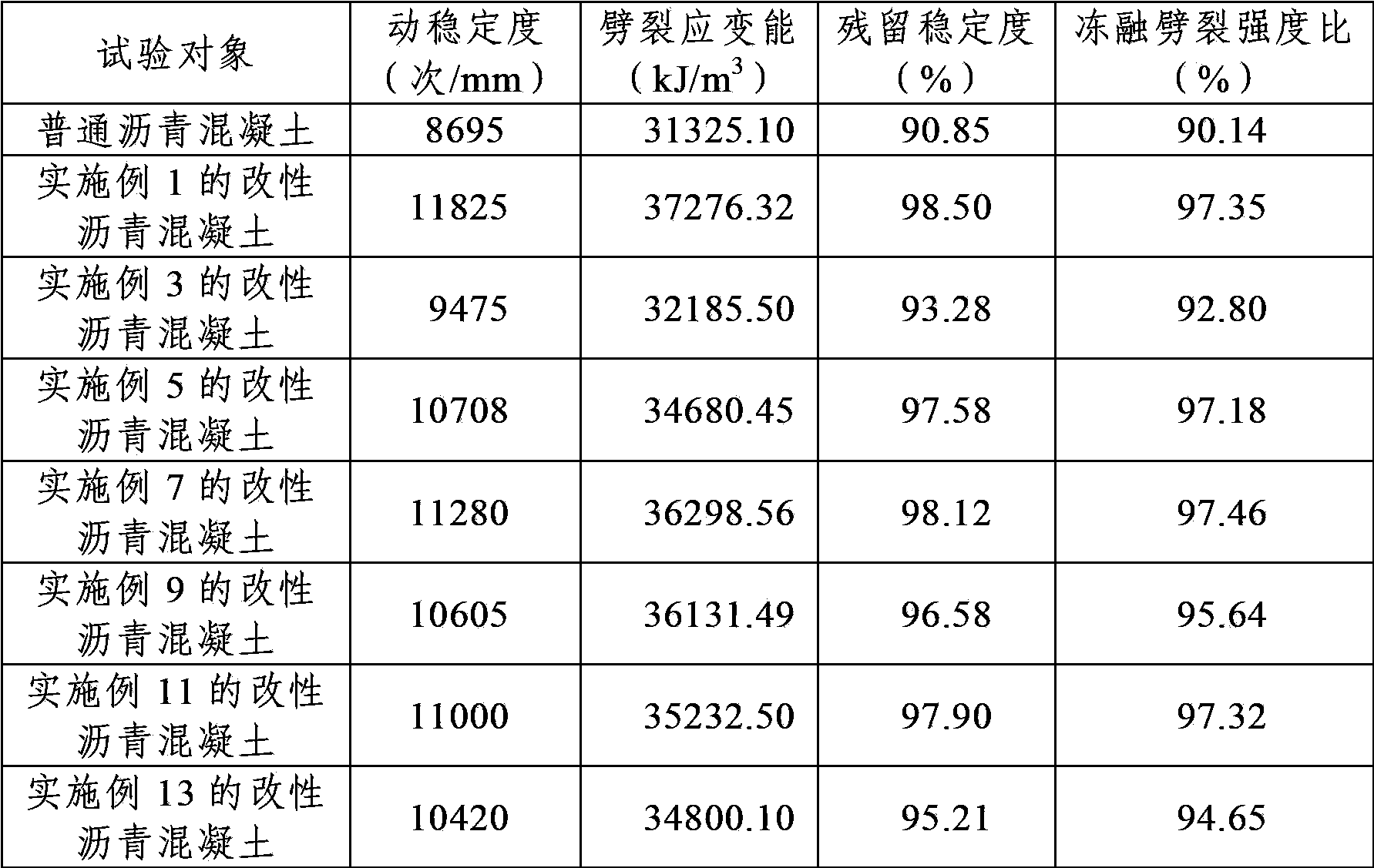

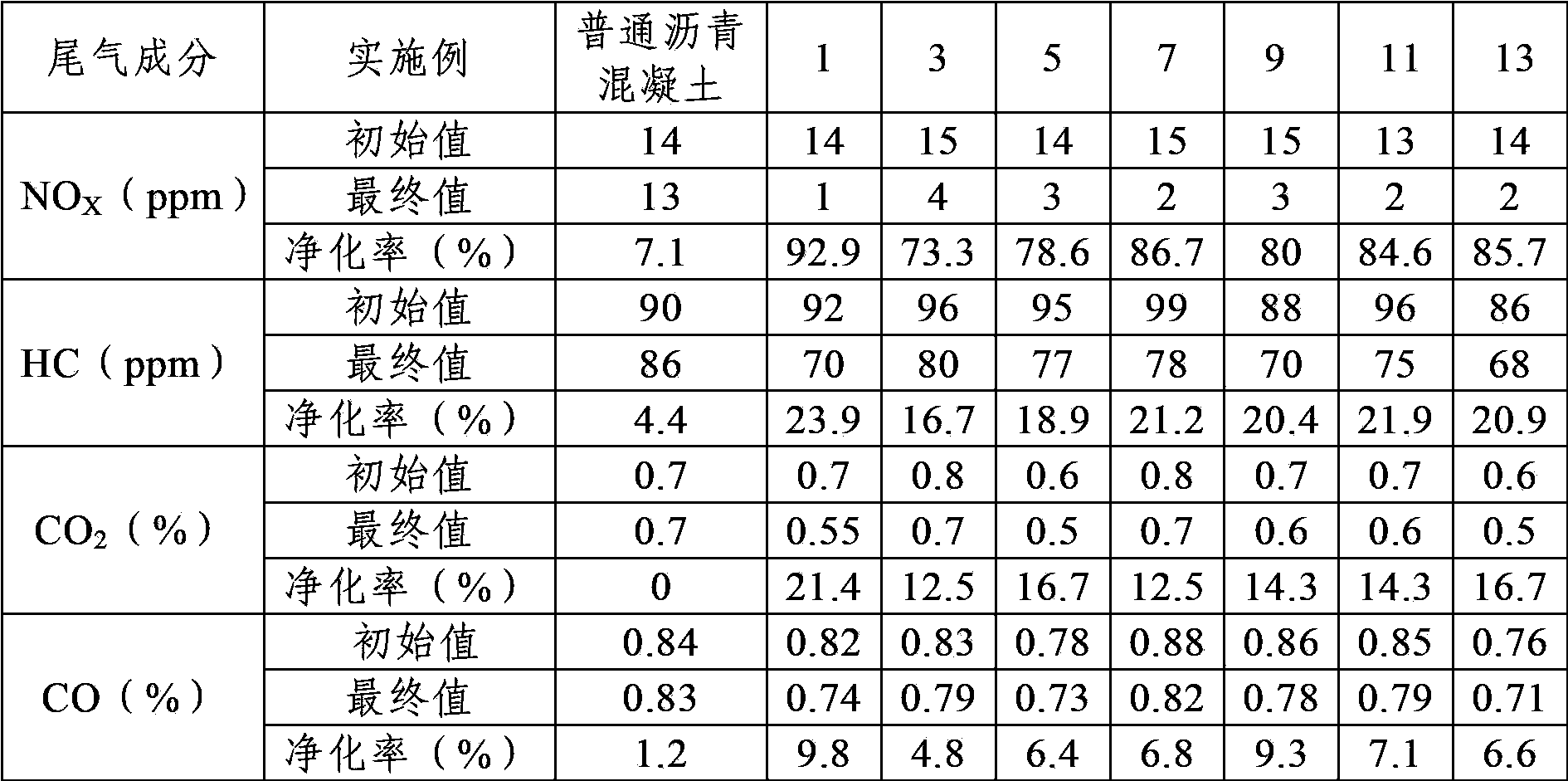

Modified asphalt concrete for purifying air

The invention discloses modified asphalt concrete for purifying air, which comprises traditional asphalt concrete and tourmaline, wherein the use quantity of the tourmaline is 10-40% of the mass of asphalt in the traditional asphalt concrete, and the tourmaline is tourmaline powder and / or tourmaline anion powder. The modified asphalt concrete has remarkable air purifying effect and can effectively purify NOX (Nitrogen Oxide and Nitrogen Dioxide), HC (Hydrocarbon Compounds), CO (Carbon Monoxide) and other harmful gases exhausted by automobiles. Meanwhile, the modified asphalt concrete has certain effect of absorbing greenhouse gas CO2 (Carbon Dioxide) and can obviously improve road surrounding environment. The modified asphalt concrete has the advantages of excellent pavement performance, simple construction technology and nontoxic and harmless raw materials and has great social benefits in the aspects of improving the application quality of asphalt pavement and protecting the environment.

Owner:CHANGAN UNIV

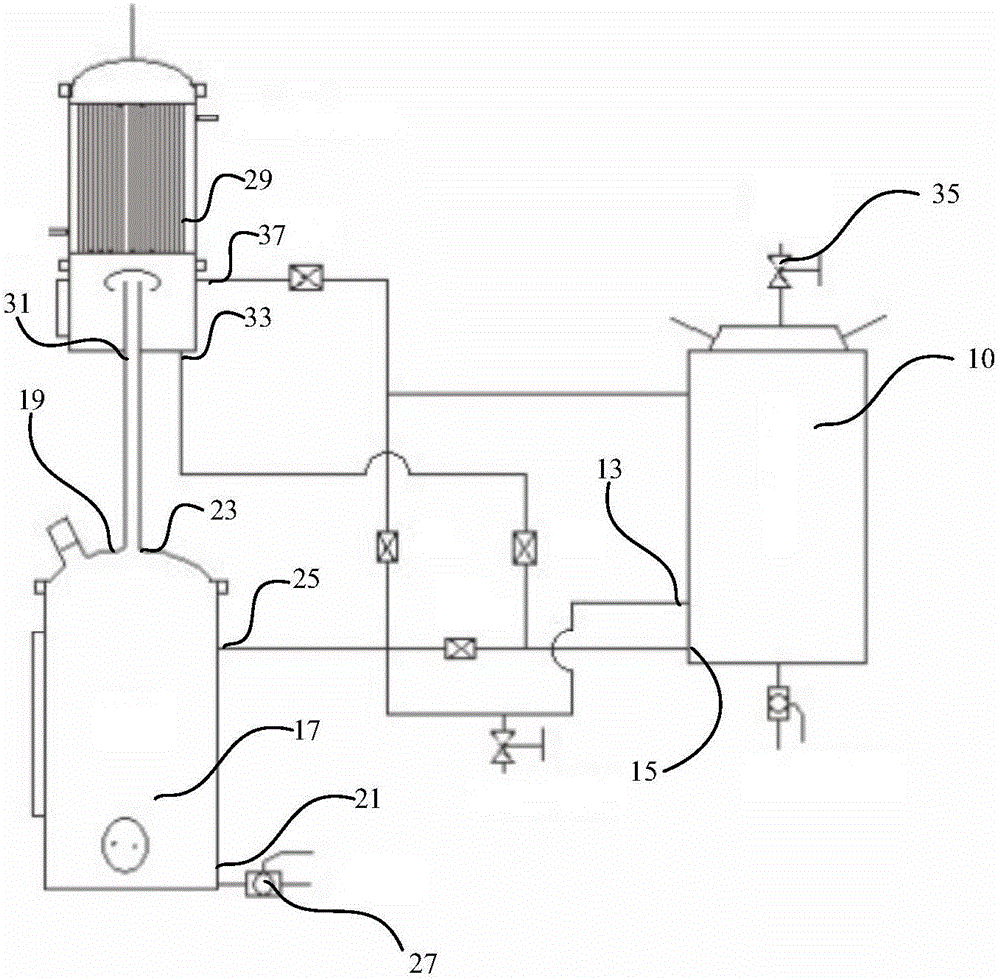

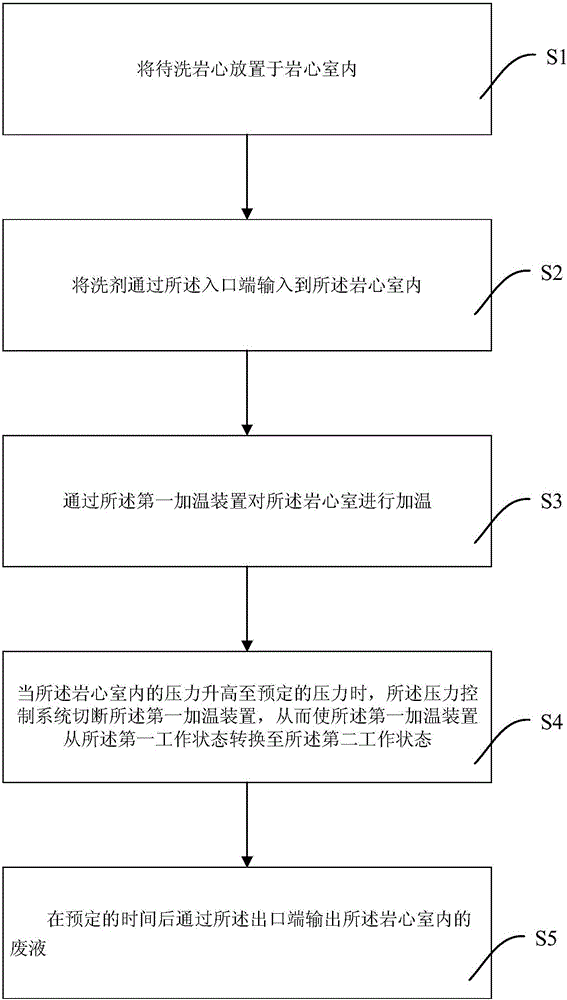

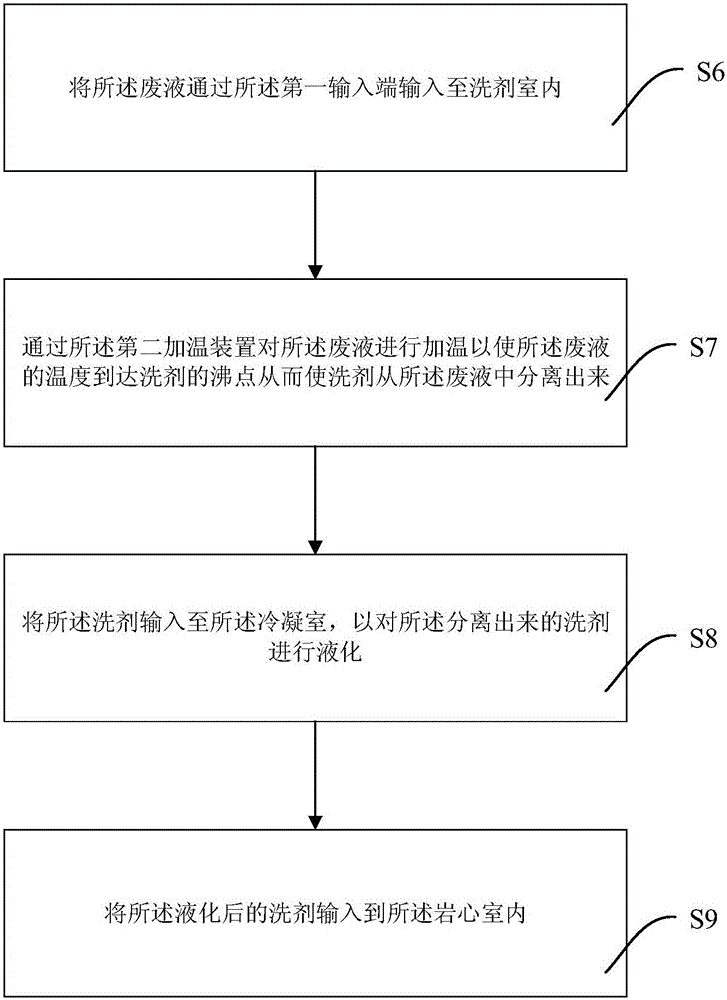

Rock core oil washing device and method

InactiveCN105092351AIncrease temperatureEasy to cleanPreparing sample for investigationRock coreControl system

The invention provides a rock core oil washing device which includes a rock core chamber having an inlet end and an outlet end, a first heating device arranged in the rock core chamber, and a pressure control system arranged in the rock core chamber; the inlet end is used for inputting a washing agent into the rock core chamber, and the outlet end is used for outputting a waste liquid in the rock core chamber; the first heating device has a first working state for heating the rock core chamber and a second working state for stopping heating of the rock core chamber; when the pressure of the rock core chamber exceeds a preset pressure, the pressure control system enables the first heating device to be turned off so as to make the first heating device have the first working state converted into the second working state. The purpose that the rock core oil washing device and method for washing a rock core under high-temperature and high-pressure conditions are provided is achieved.

Owner:PETROCHINA CO LTD

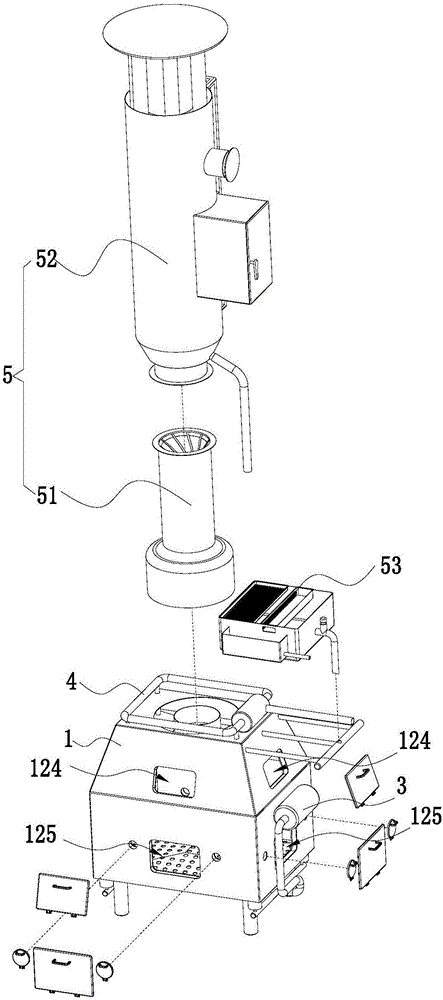

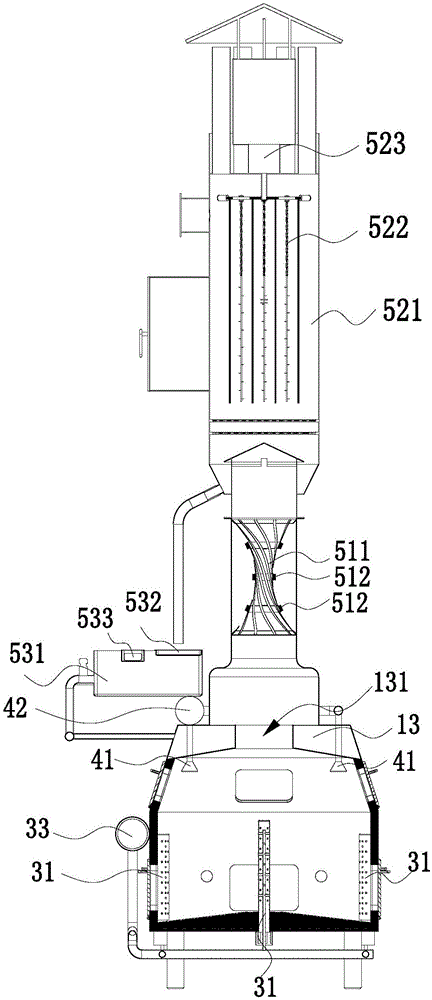

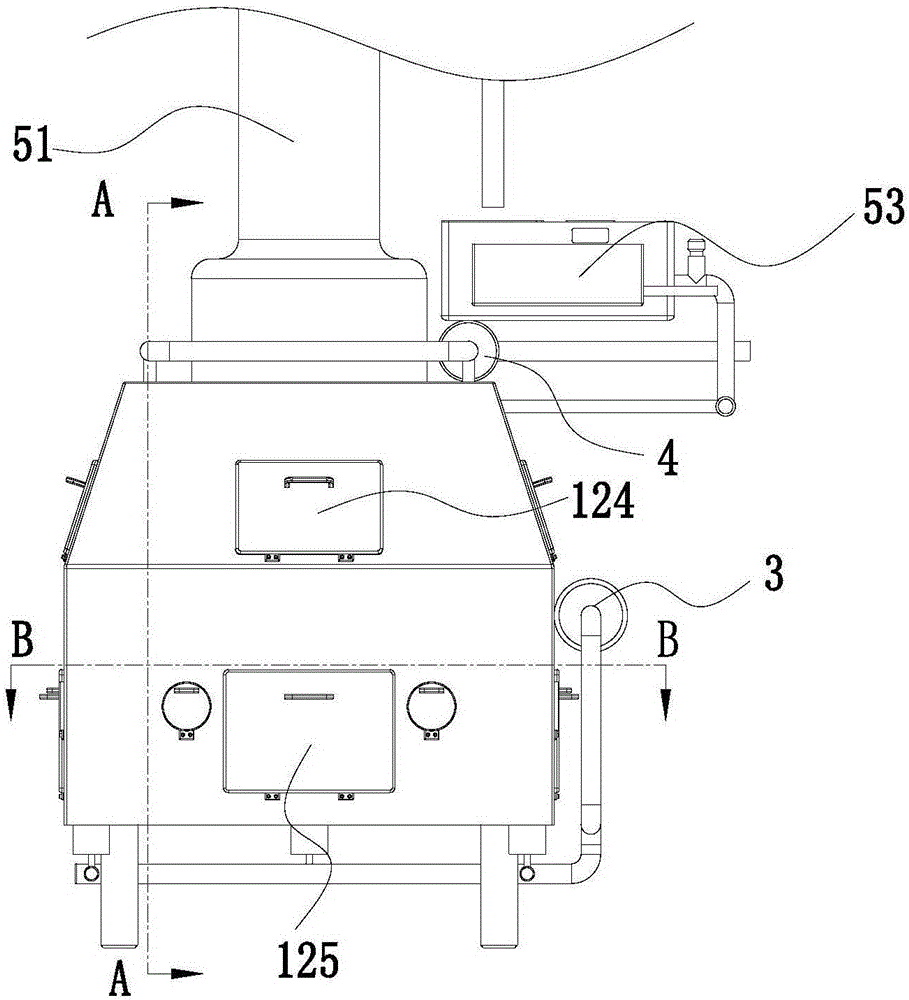

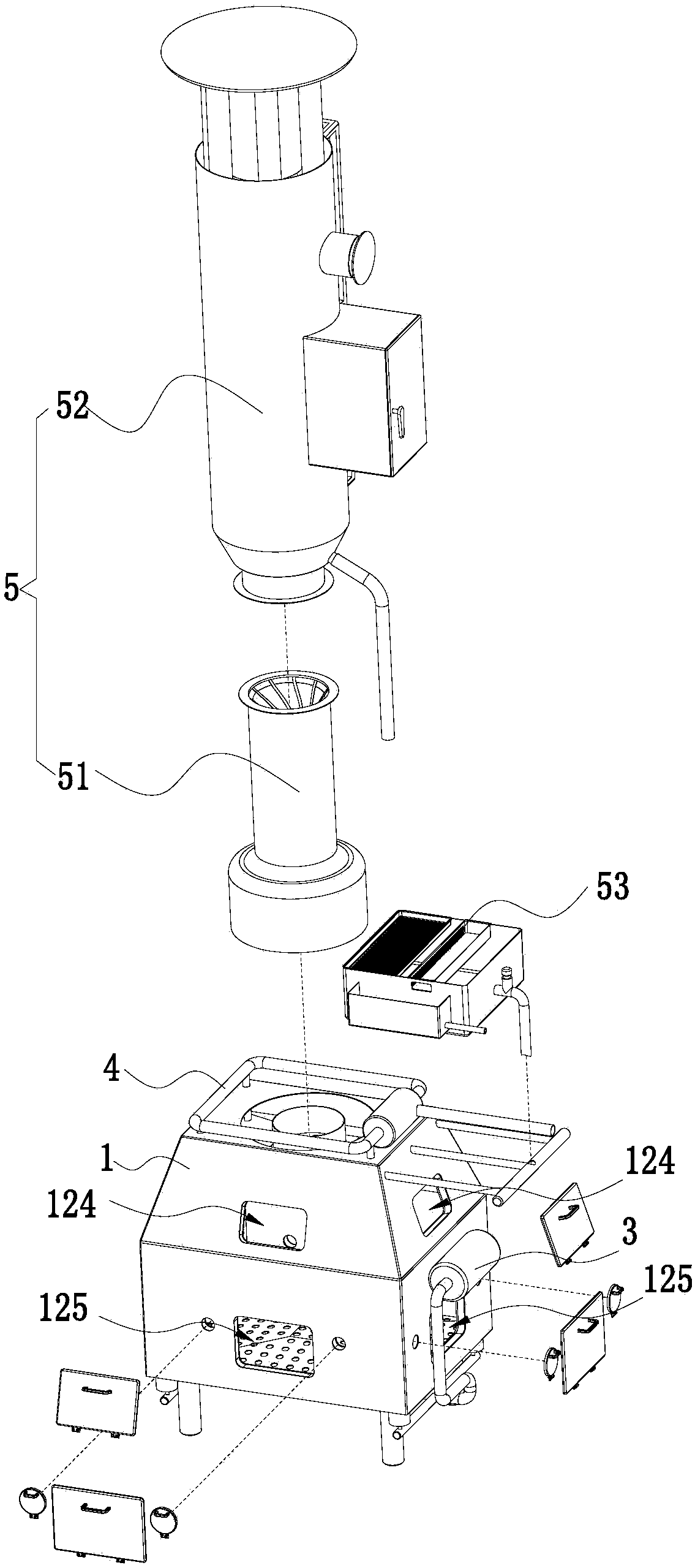

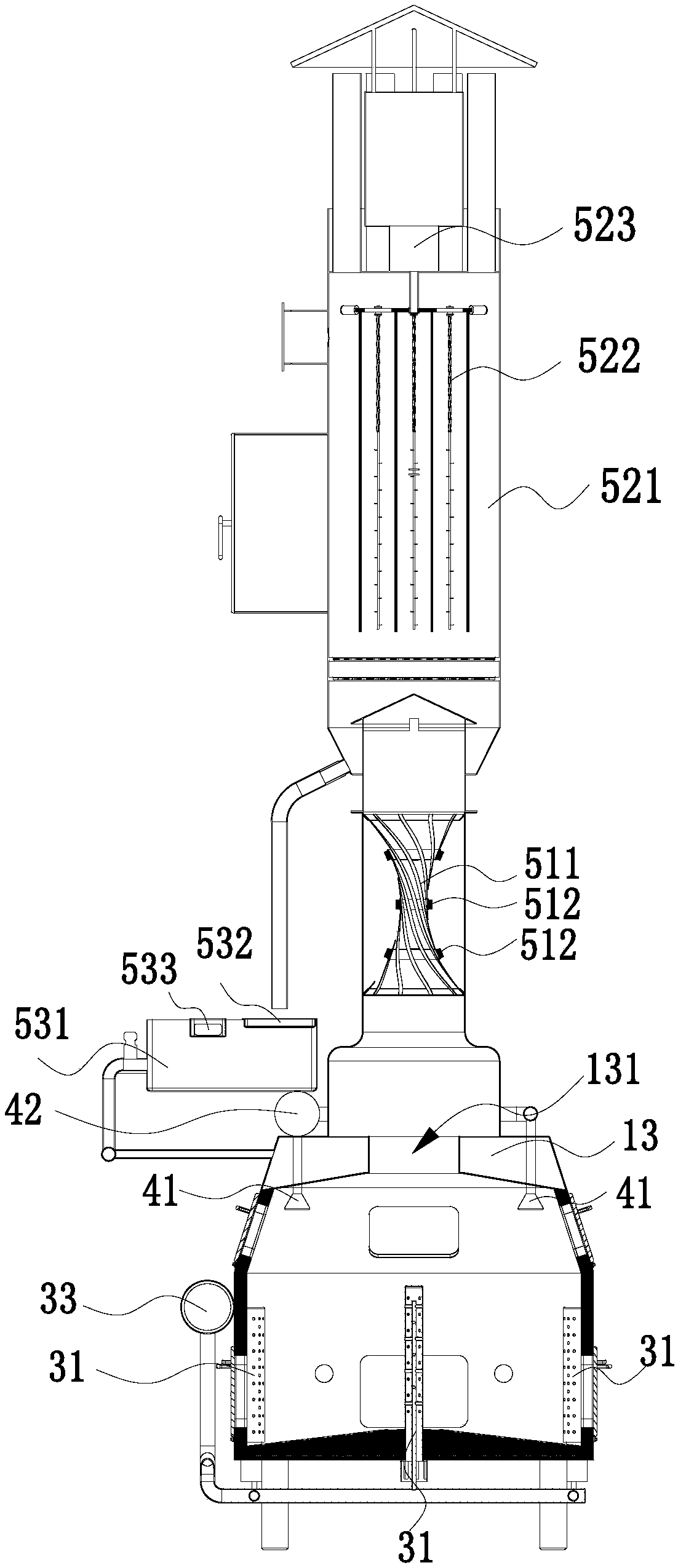

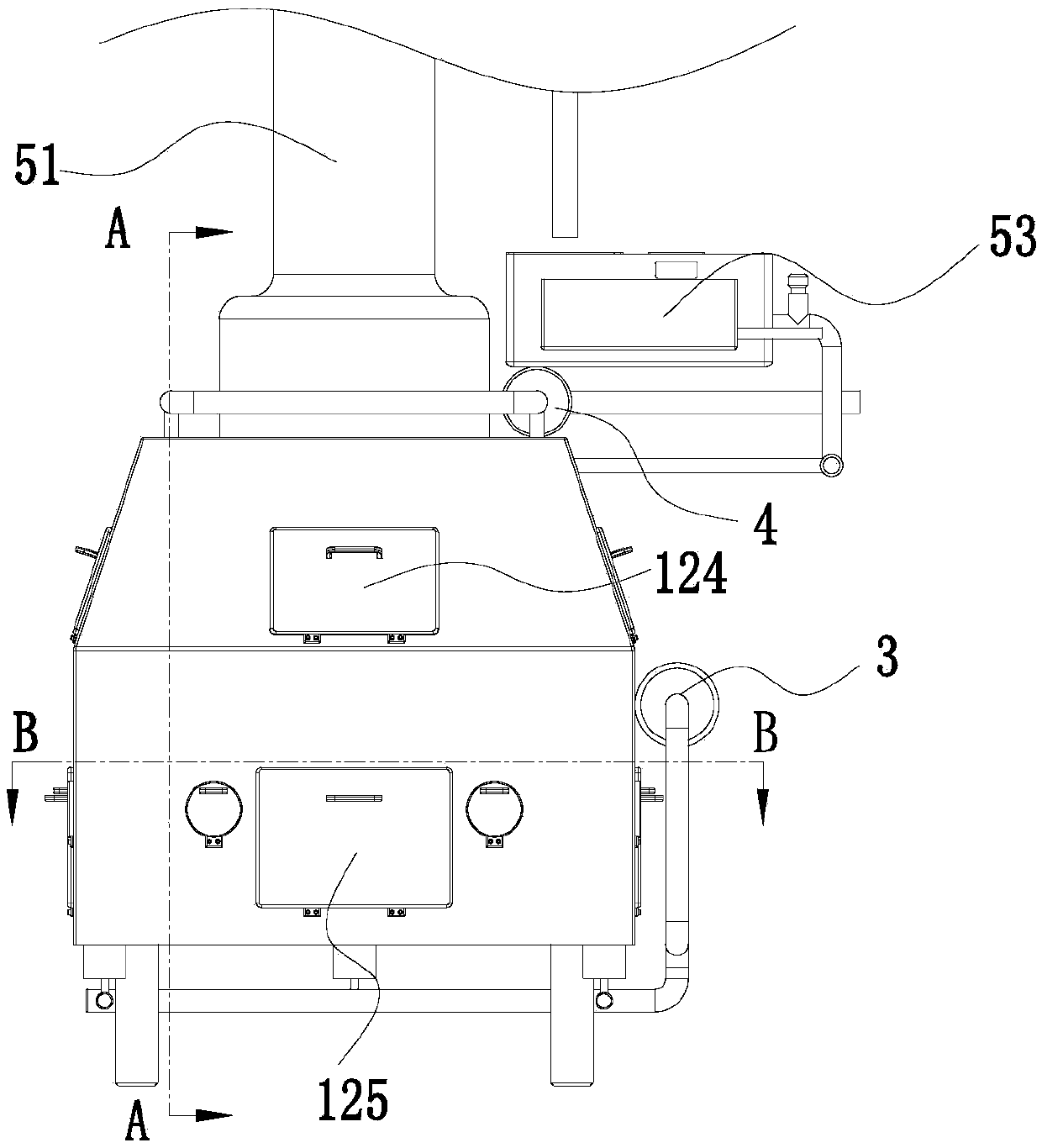

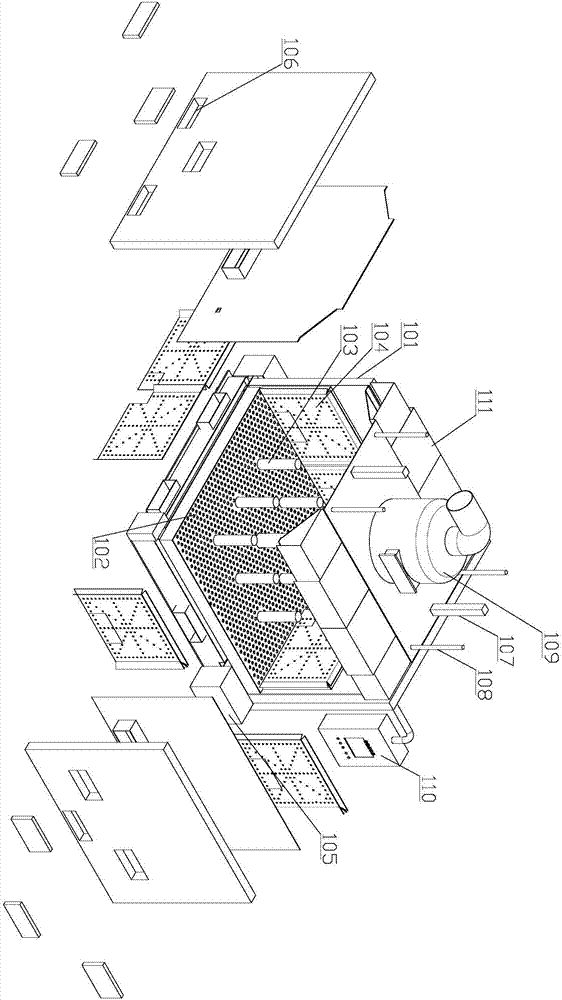

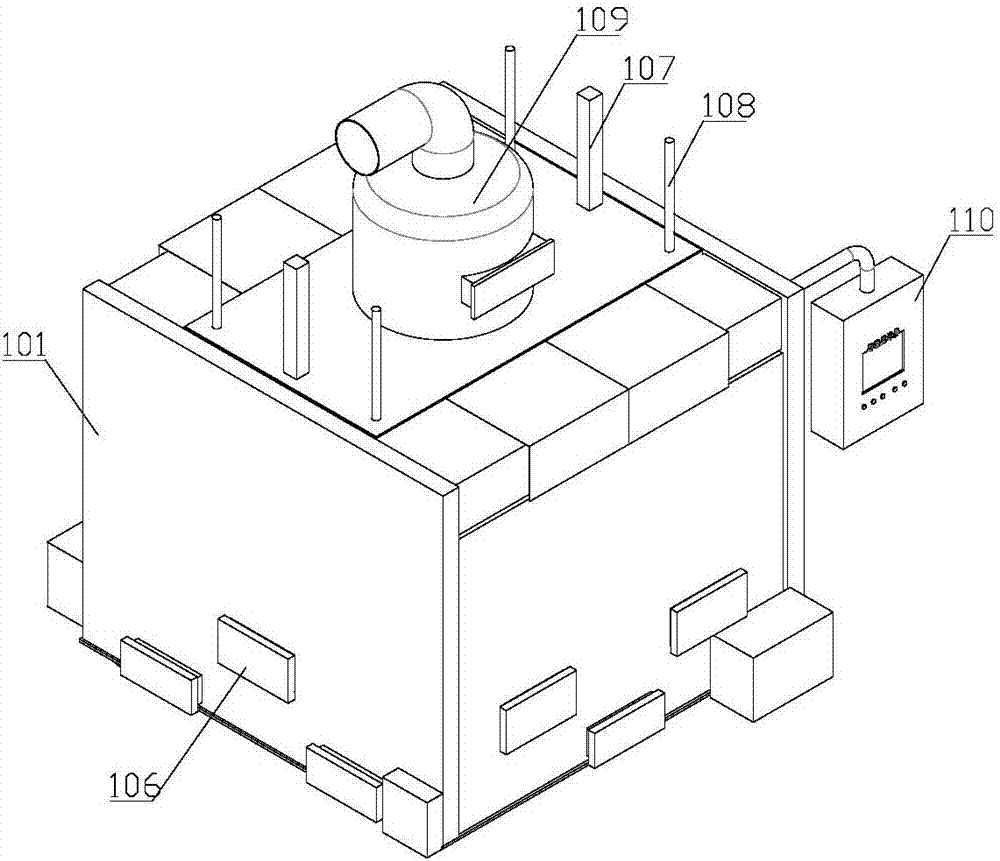

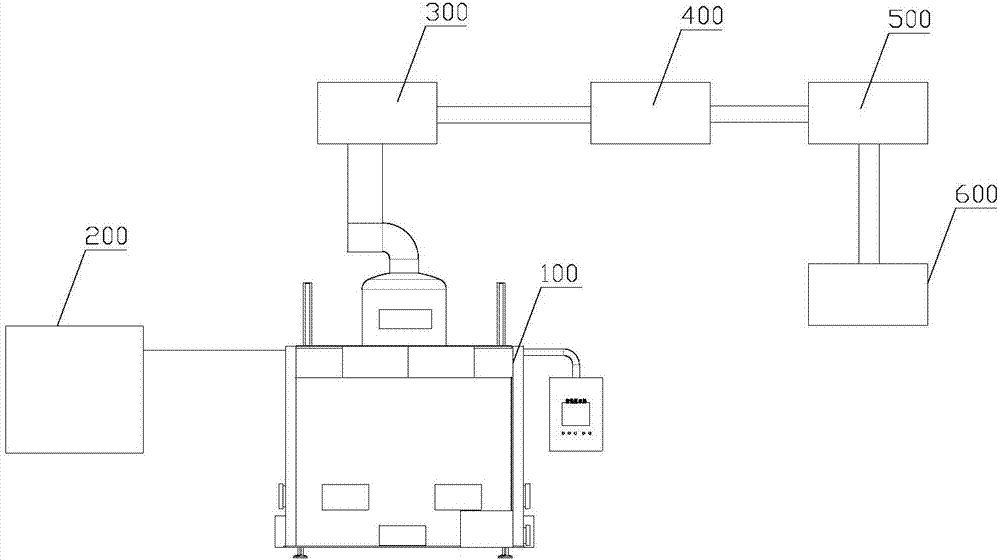

Domestic waste treatment device

ActiveCN106524169AActivation energyIntensified movementSolid waste disposalTransportation and packagingProduct gasOxygen

The invention relates to the technical field of environmentally friendly devices and provides a domestic waste treatment device. The domestic waste treatment device comprises a furnace body, a plurality of magnetizing devices and an air inlet device; each magnetizing device is arranged on the furnace body; and the air inlet device penetrates into the furnace body from outside. According to the domestic waste treatment device, the multiple magnetizing devices arranged on the furnace body are utilized to form a magnetic field environment for simulating the interior of the earth in the furnace body; magnetizing treatment can be conducted on oxygen, other gases and solid domestic waste in the furnace body, so that energy needed for decomposing solid waste is reduced greatly, no extra energy source need be supplied in the whole decomposing process, and consequently the domestic waste treatment device is more environmentally friendly and saves energy.

Owner:广东熠森能环保科技有限公司

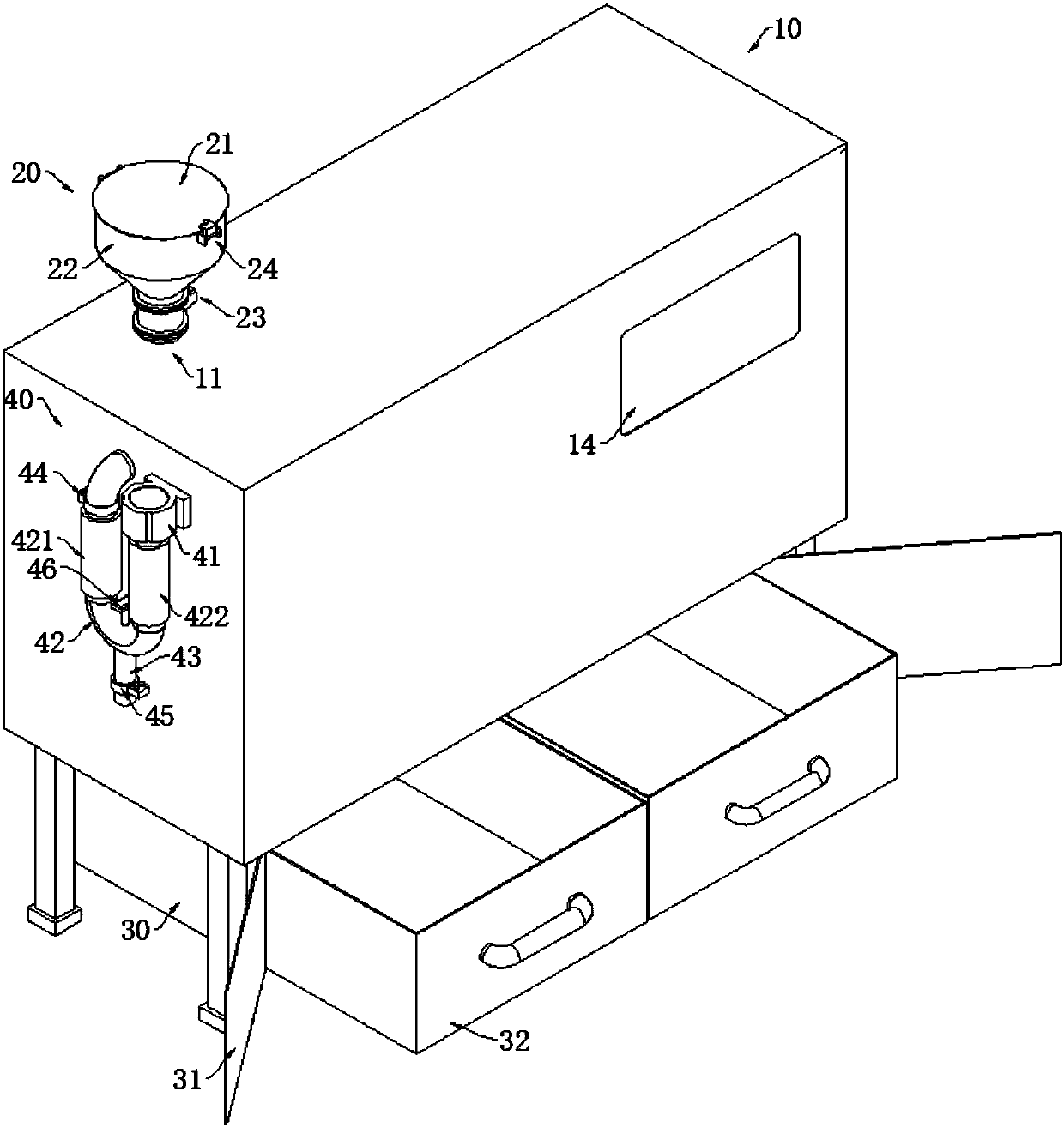

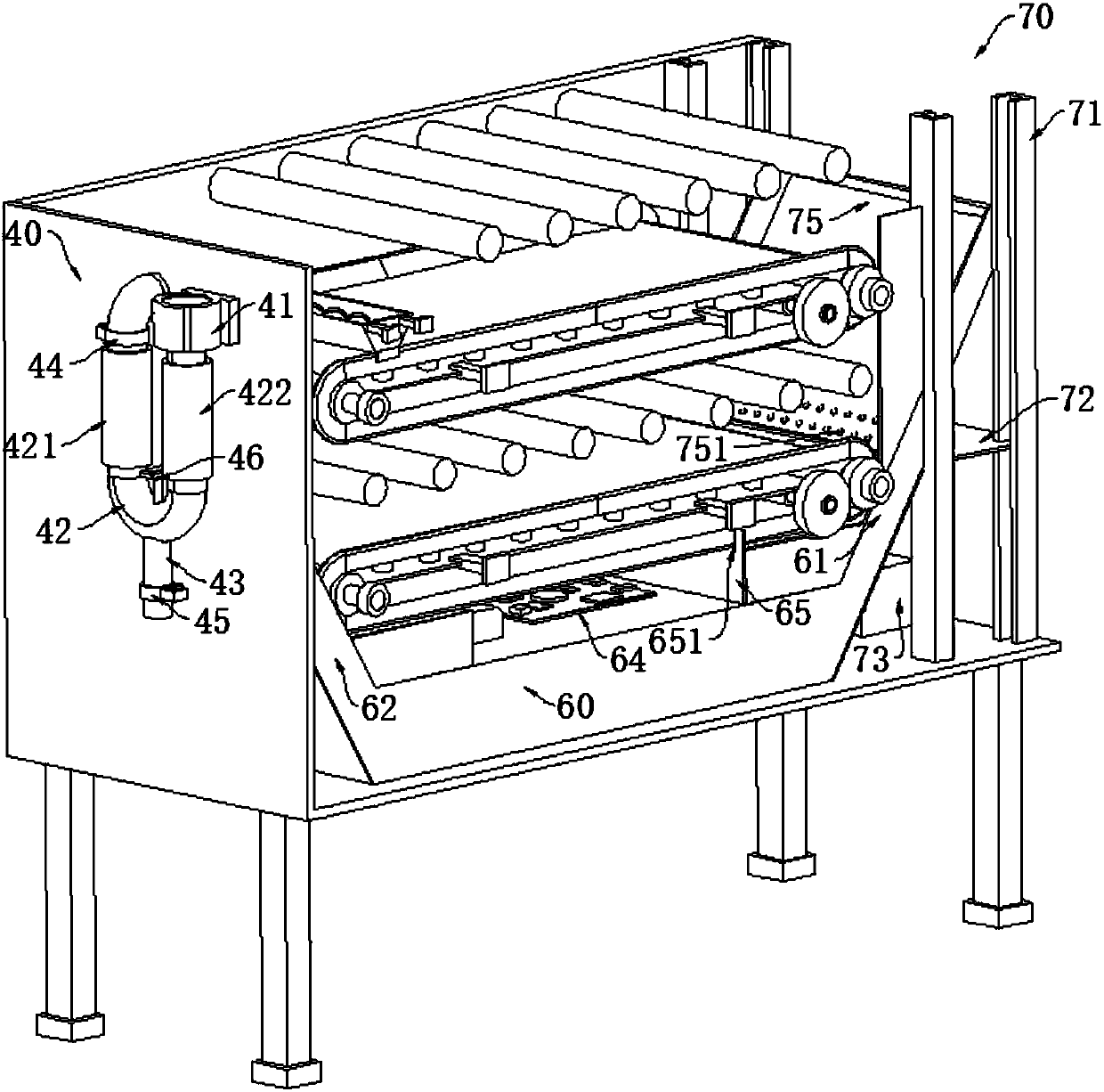

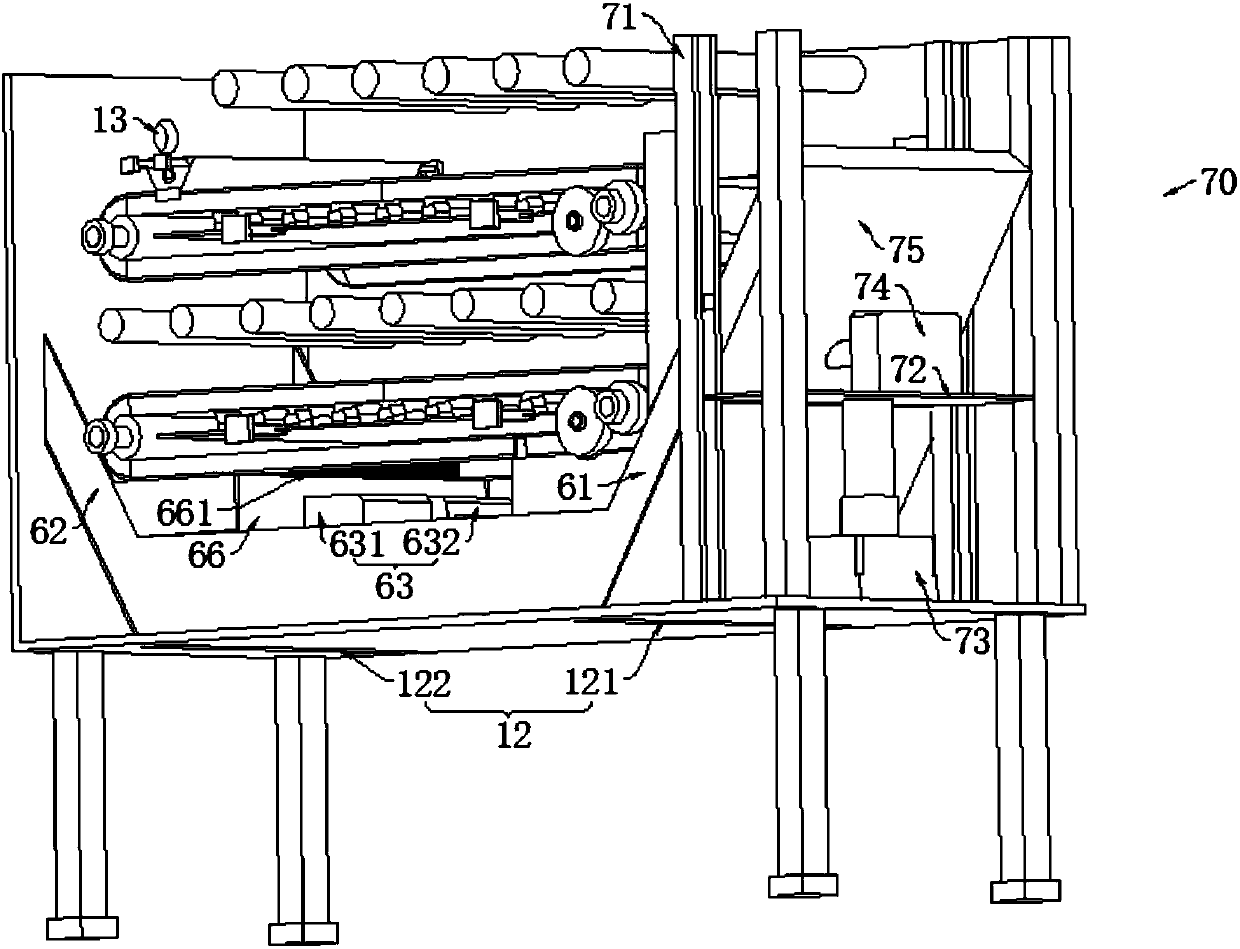

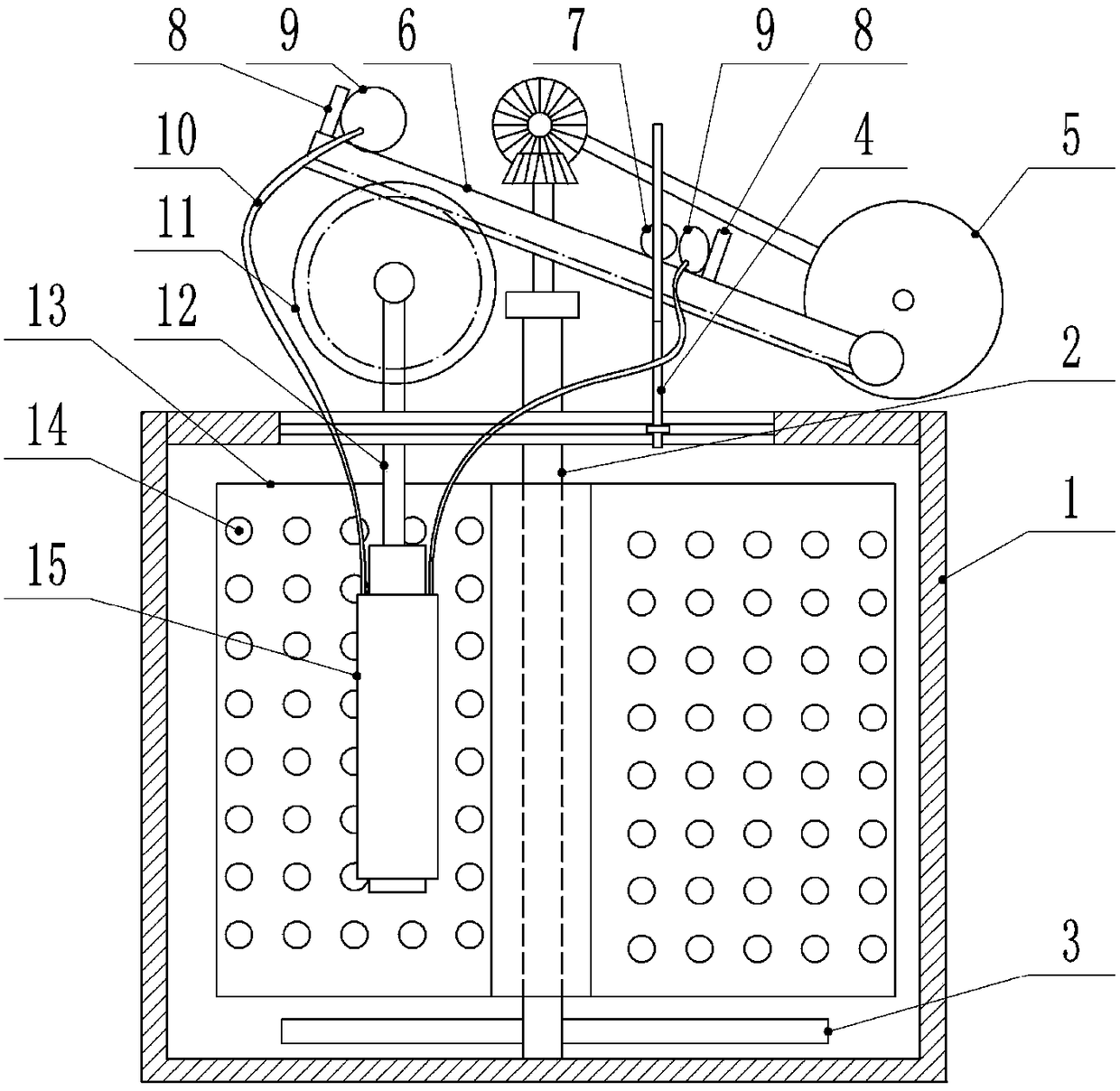

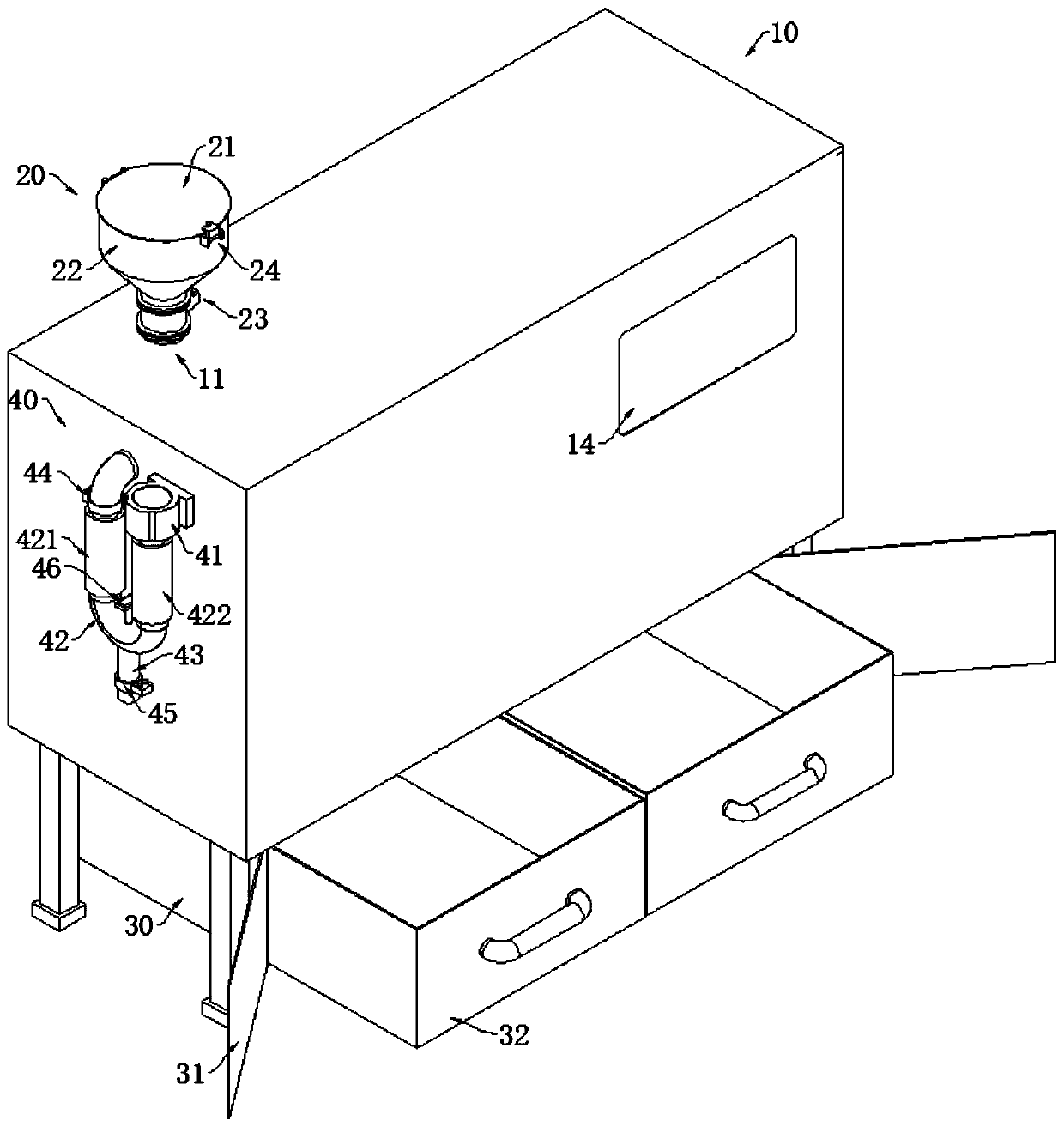

Medicinal material drying equipment

InactiveCN107702436AMaintain colorLow boiling pointDrying solid materials with heatDrying solid materials without heatVacuum pumpingBristle

The invention provides medicinal material drying equipment. The medicinal material drying equipment comprises a drying box, a feed hopper, a receiving box and a vacuum pumping device. The drying box is internally provided with a drying device, a material collection block and a lifting device. The drying device comprises a first drying unit and a second drying unit. The first drying unit and the second drying unit each comprises a material conveyor belt, ultrasonic transducers located below the material conveyor belt, a driving motor and an infrared ray lamp pole located above the material conveyor belt. A material scattering device is arranged above the first drying unit. Material retaining plates are arranged below the second drying unit. Limiting grooves and bristles are arranged above the material retaining plates. The lifting device is located on one side of the drying device. The medicinal material drying equipment conducts drying on medicinal materials through combination of ultrasound and infrared, is good in drying effect and capable of completely maintaining the original color, luster and flavor of the medicinal materials, conducts vacuum pumping on the interior of the drying box through the vacuum pumping device, can improve the drying efficiency and prevent vapor from wetting the medicinal materials again and is good in drying effect.

Owner:成都菲斯普科技有限公司

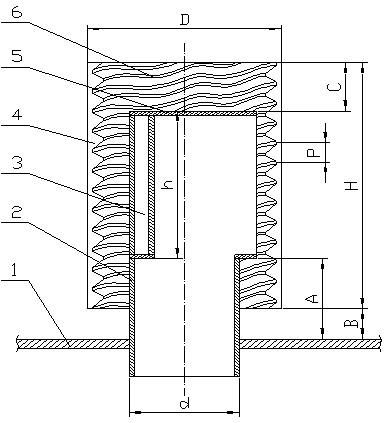

High-efficiency multistage demister

The invention discloses a high-efficiency multistage demister. The high-efficiency multistage demister comprises a plurality of demisting components; each demisting component comprises a gas riser pipe and an outer barrel; the outer barrel is arranged on the outer side of the gas riser pipe and located on the same axis as the gas riser pipe; the inner surface of the outer barrel is provided with spiral fins; the gas riser pipe is fixed on a tray; the top of the gas riser pipe is provided with a sealing cover; and a rectifying passage is arranged on the circumference of the gas riser pipe. Thedemister of the invention realizes the separation of droplets from gas by rectification, acceleration and scraping effect in the flowing process of fluids. The demister of the invention has the advantages of simple structure, convenient installation and small possibility of scale formation, and can effectively realize gas-liquid separation and reduce entrainment of mist.

Owner:CHINA PETROLEUM & CHEM CORP +1

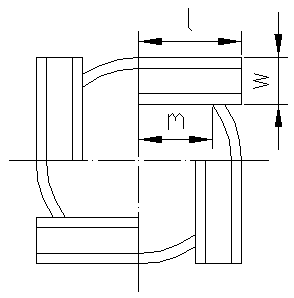

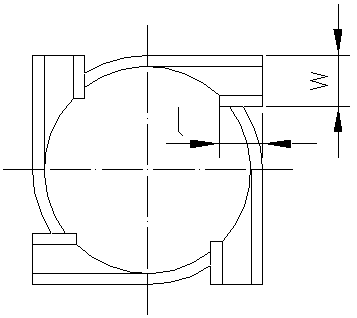

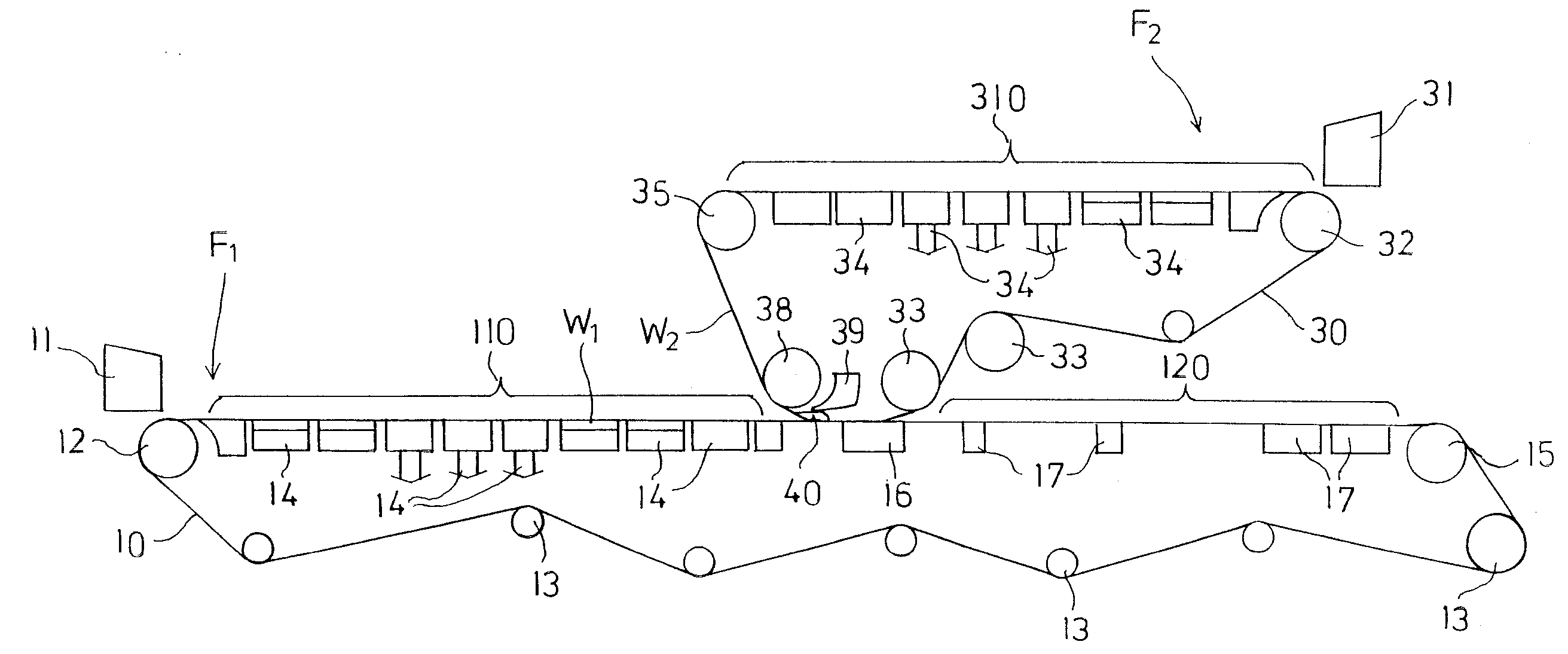

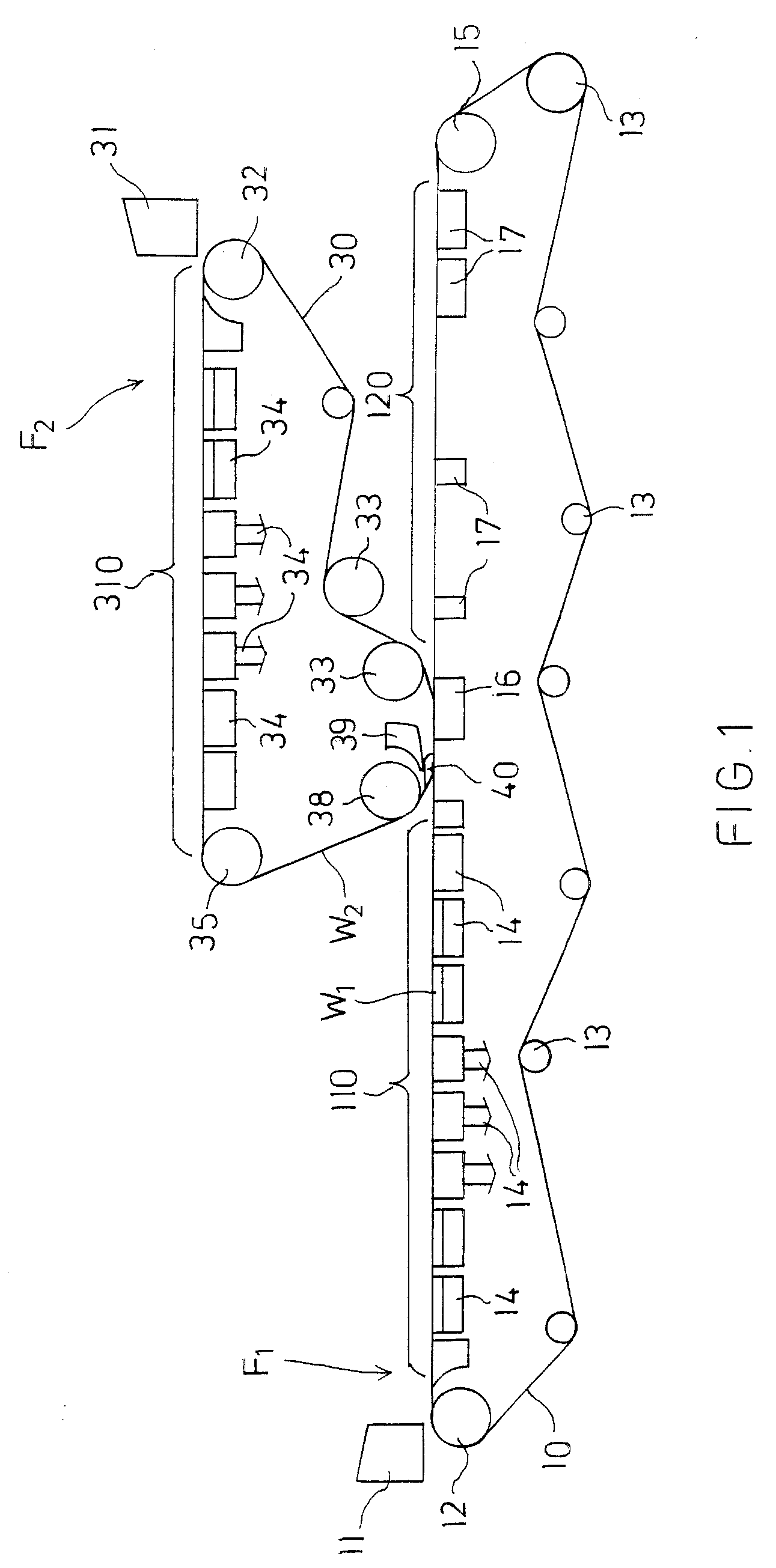

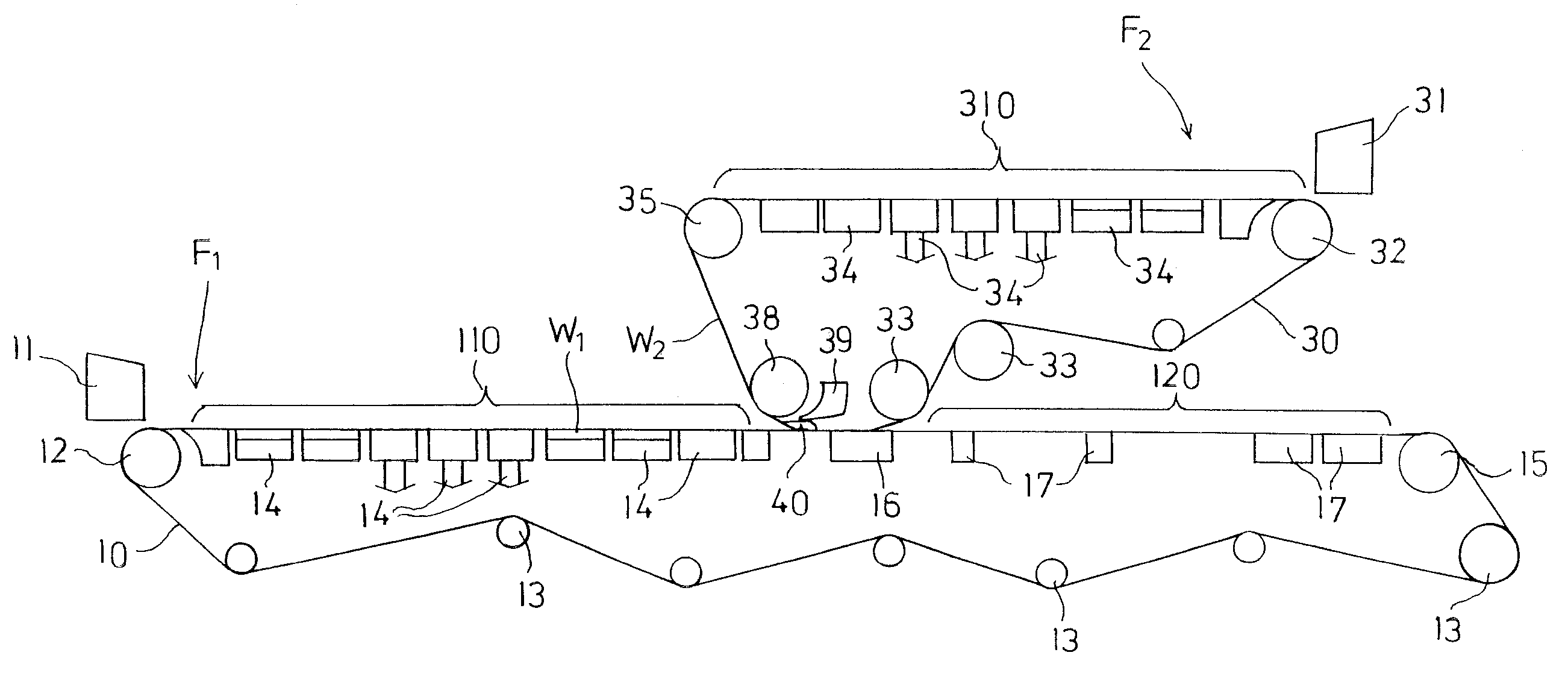

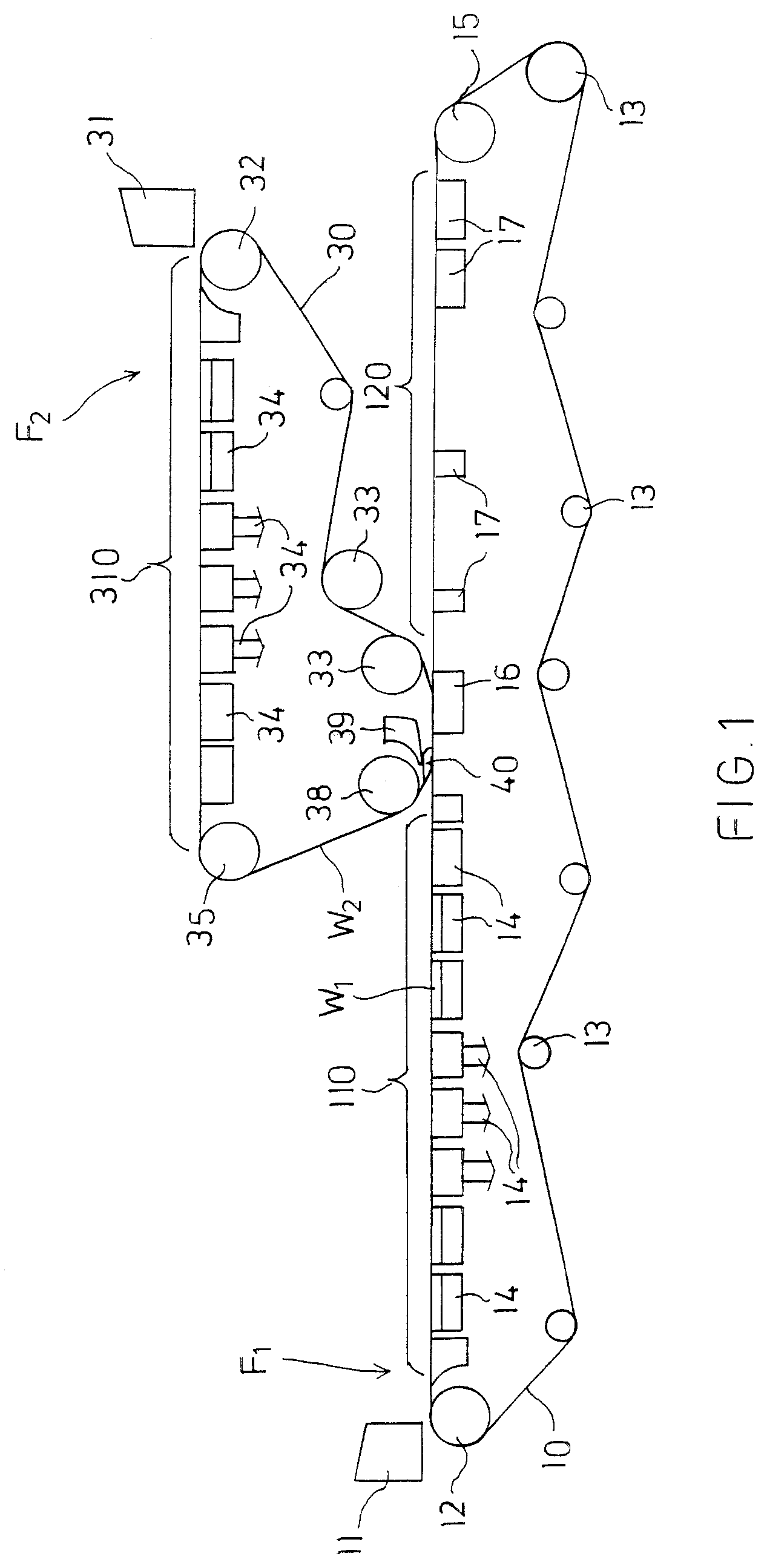

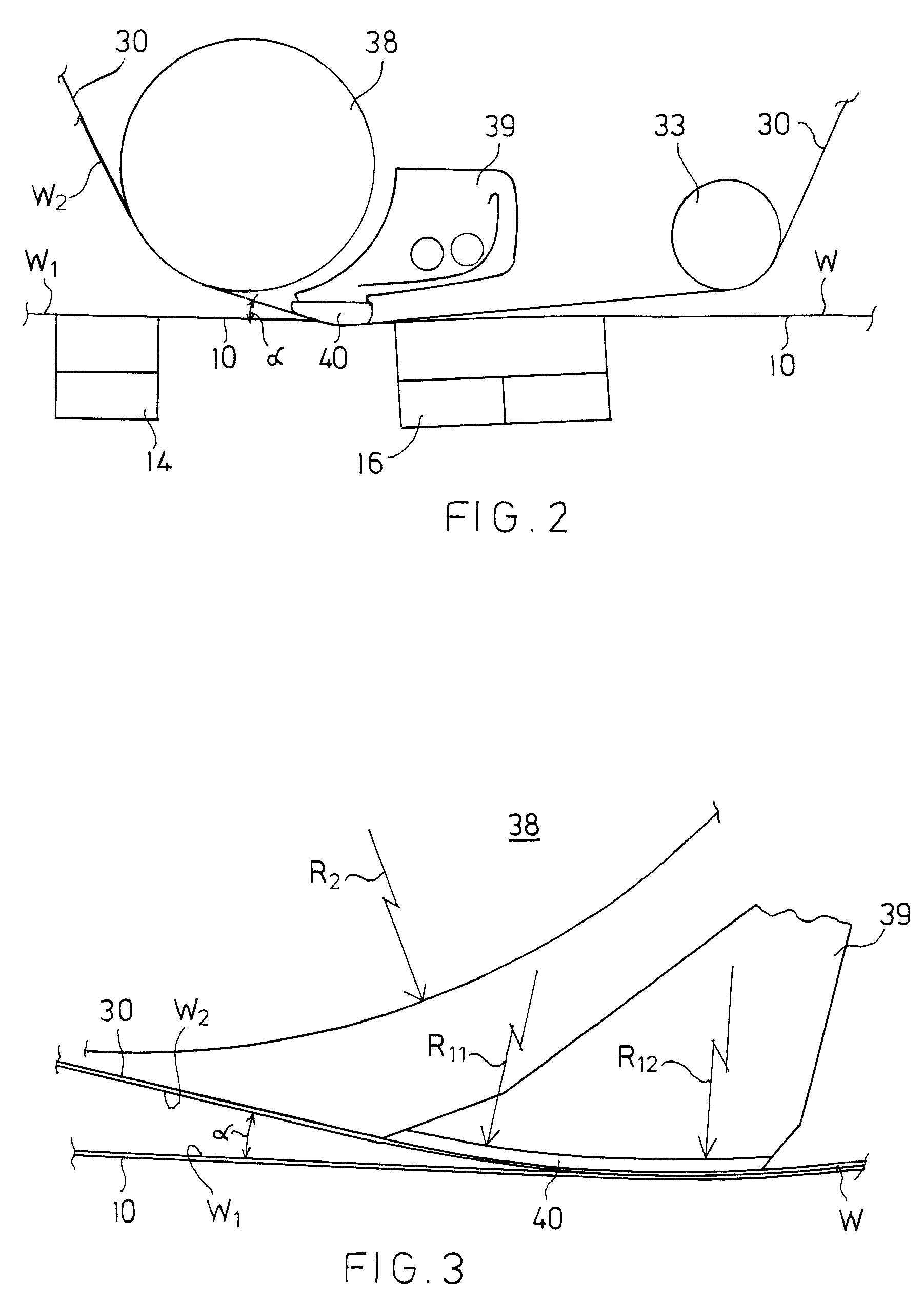

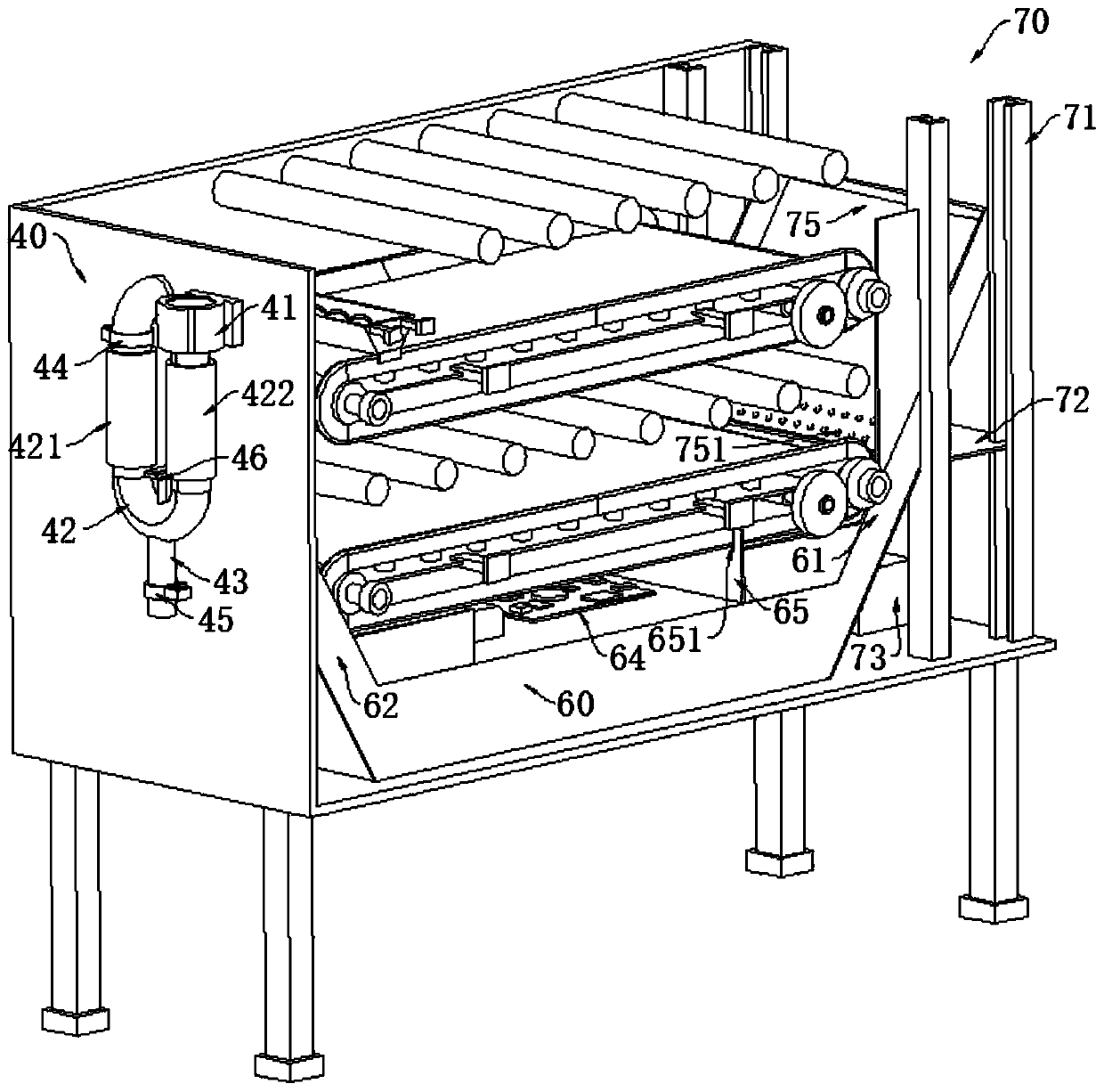

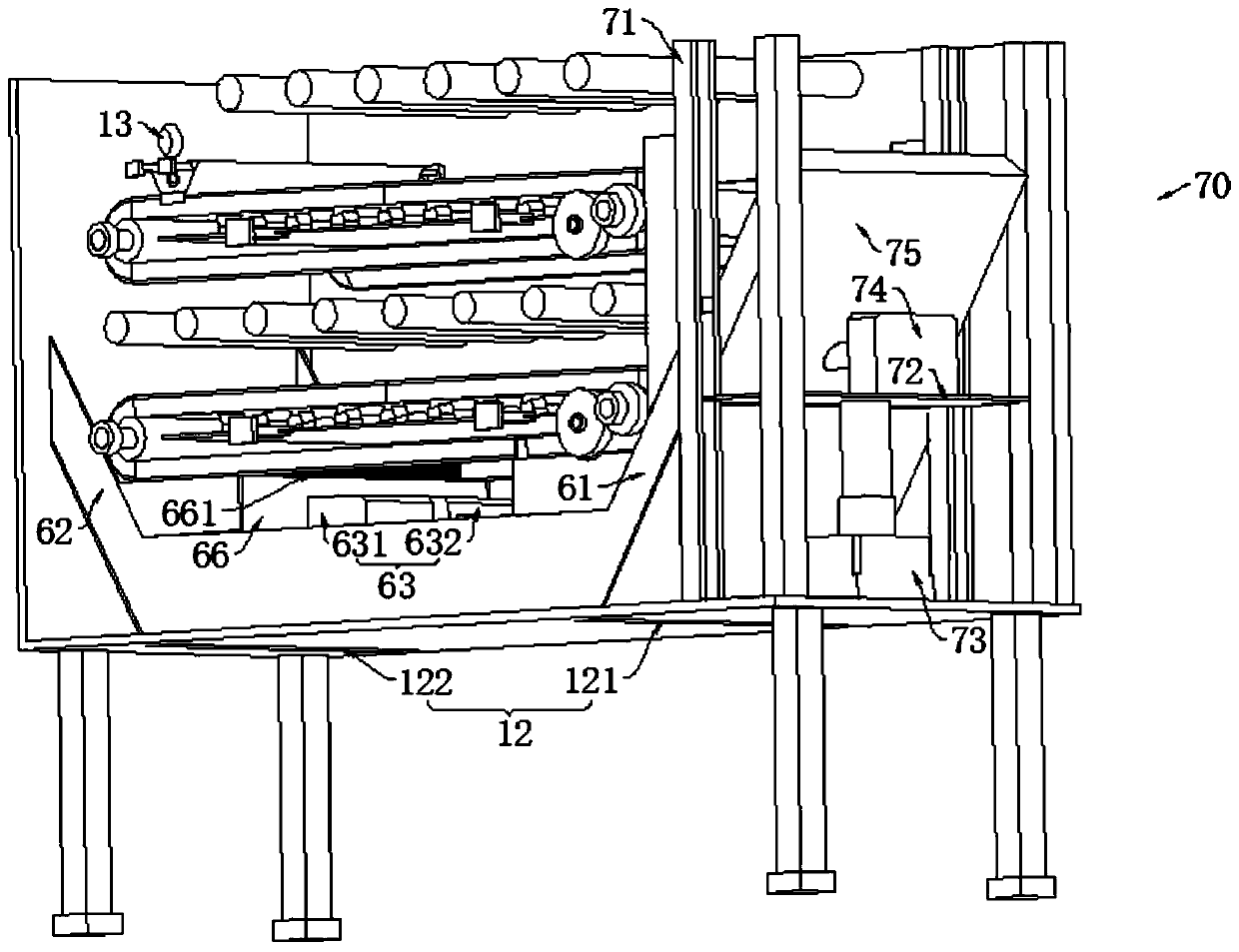

Web-Forming Section and Method for Manufacturing Multi-Layer Web

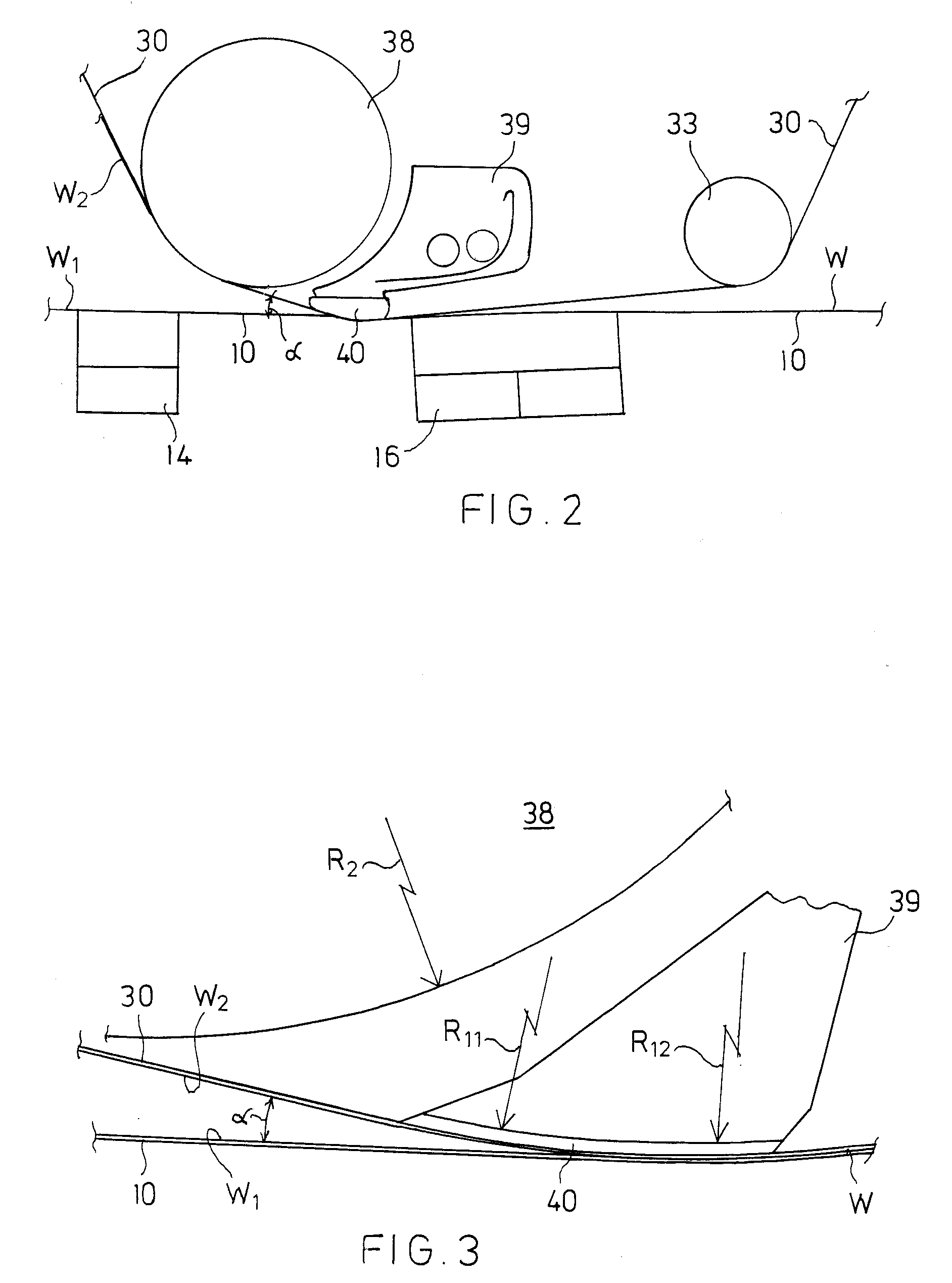

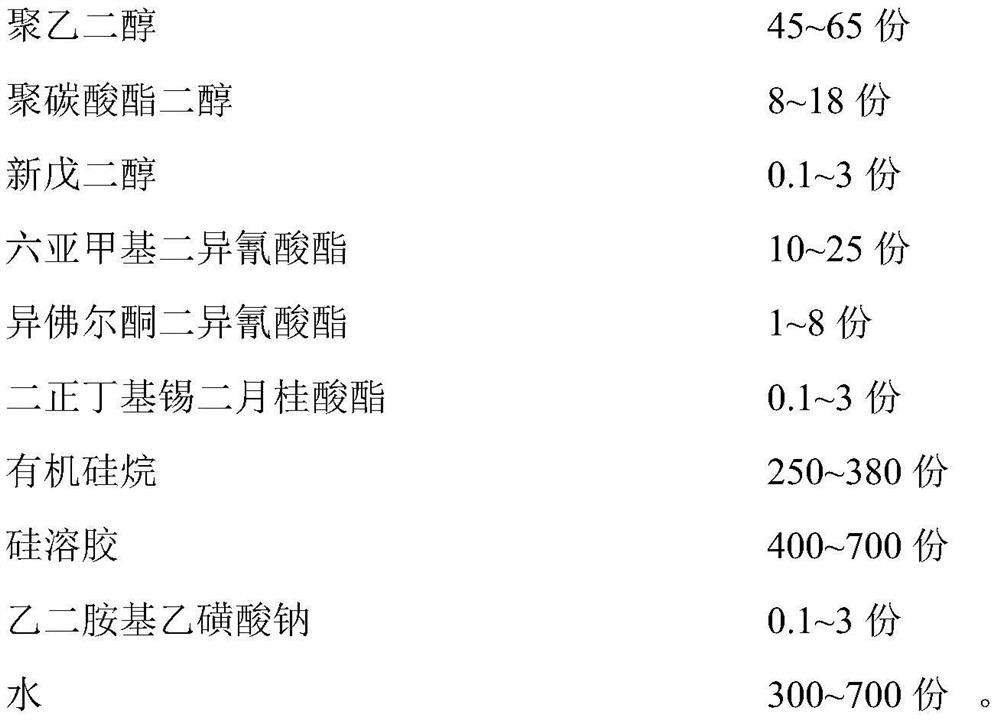

InactiveUS20090165973A1Widen running windowIncrease productionNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFiber layer

A web-forming section of a paper or board machine has a first web-forming unit with a first fiber layer (W1) formed on a first wire (10); a second web-forming unit with a second fiber layer (W2) formed on a second wire (30); and a couch shoe (39) over a curved deck (40) of which the fiber layers (W1, W2) are guided for joining them together. The second fiber layer (W2) is brought to the couch shoe (39) at an angle (α) of less than 20°, advantageously less than 15° in relation to the approach direction of the first fiber layer (W1). The couch shoe (39) is provided with underpressure and the radius of curvature of its deck (40) is usually larger than the radius of curvature of a guide roll (38) preceding it. By the couch shoe, the fiber layers can be joined together wetter than usual.

Owner:VALMET TECH INC

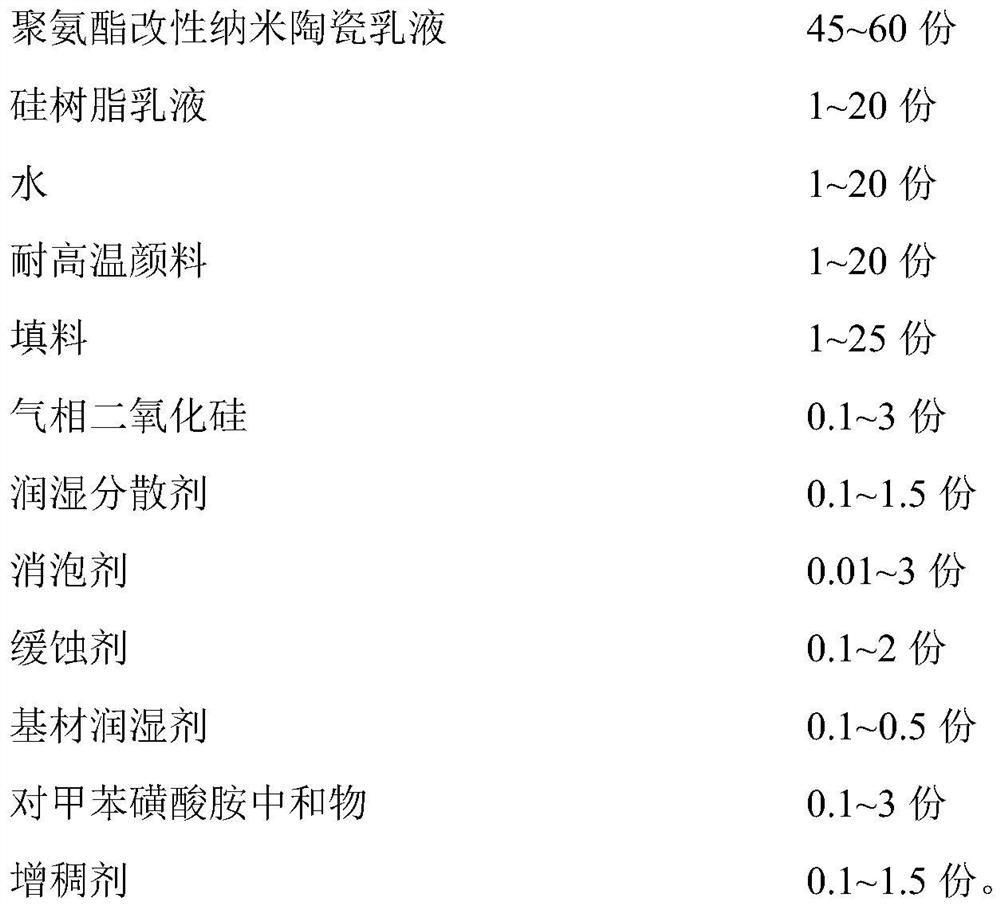

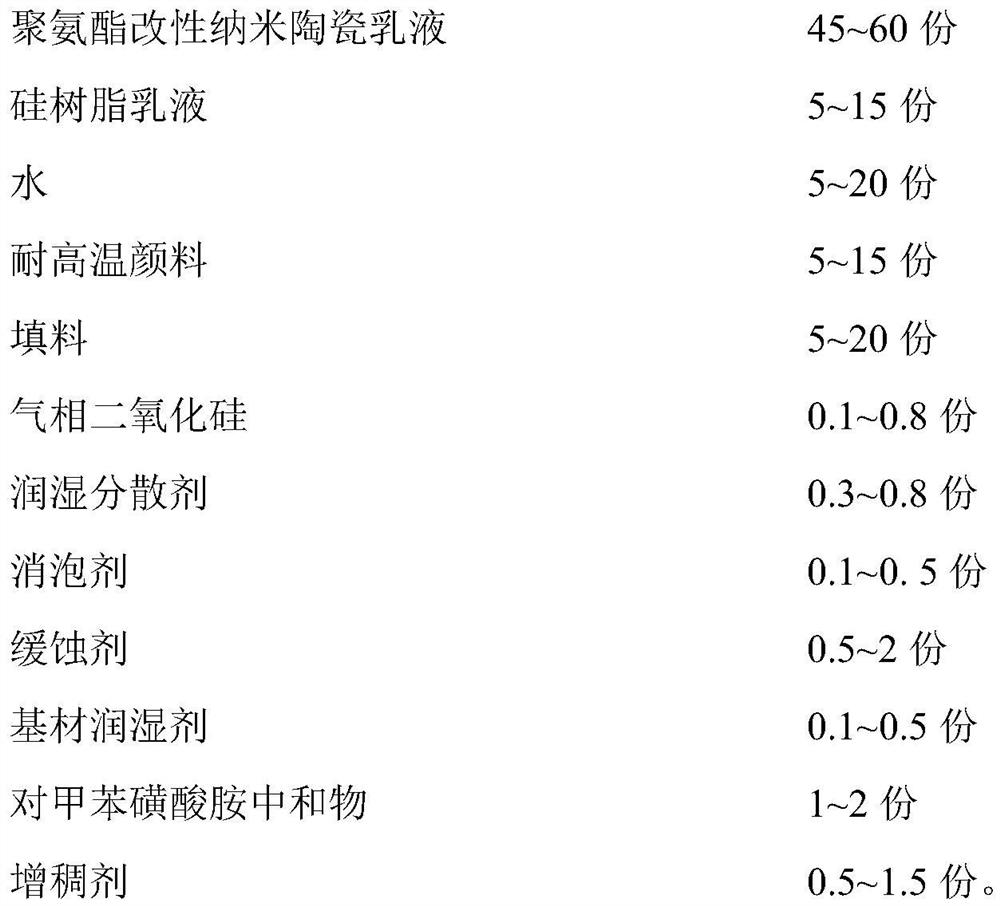

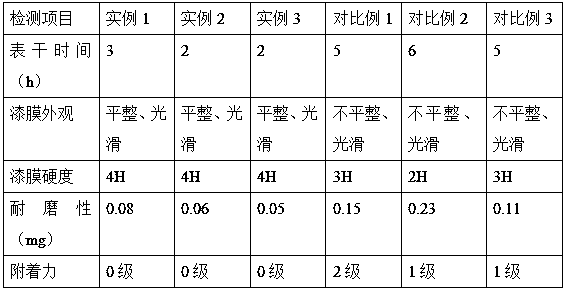

Water-based ceramic coating and preparation method thereof

ActiveCN112094514AImprove bending resistanceImprove brittle connectionsFireproof paintsAnti-corrosive paintsCeramic coatingNanoceramic

The invention discloses a high-toughness water-based ceramic coating. The coating is a water-based, single-component, baked and dried product and is prepared from polyurethane modified nano ceramic emulsion, silicon resin emulsion, a high-temperature-resistant pigment, a filler, auxiliaries, an ammonium toluene-4-sulphonate neutralizer and water. The coating is convenient to construct and extremely low in coating VOC emission, has excellent flame retardance, heat resistance, corrosion medium shielding, bending resistance and impact resistance, and is an excellent choice for high-temperature-resistance and high-durability anti-corrosion protective coating.

Owner:NANJING CHANGJIANG PAINT

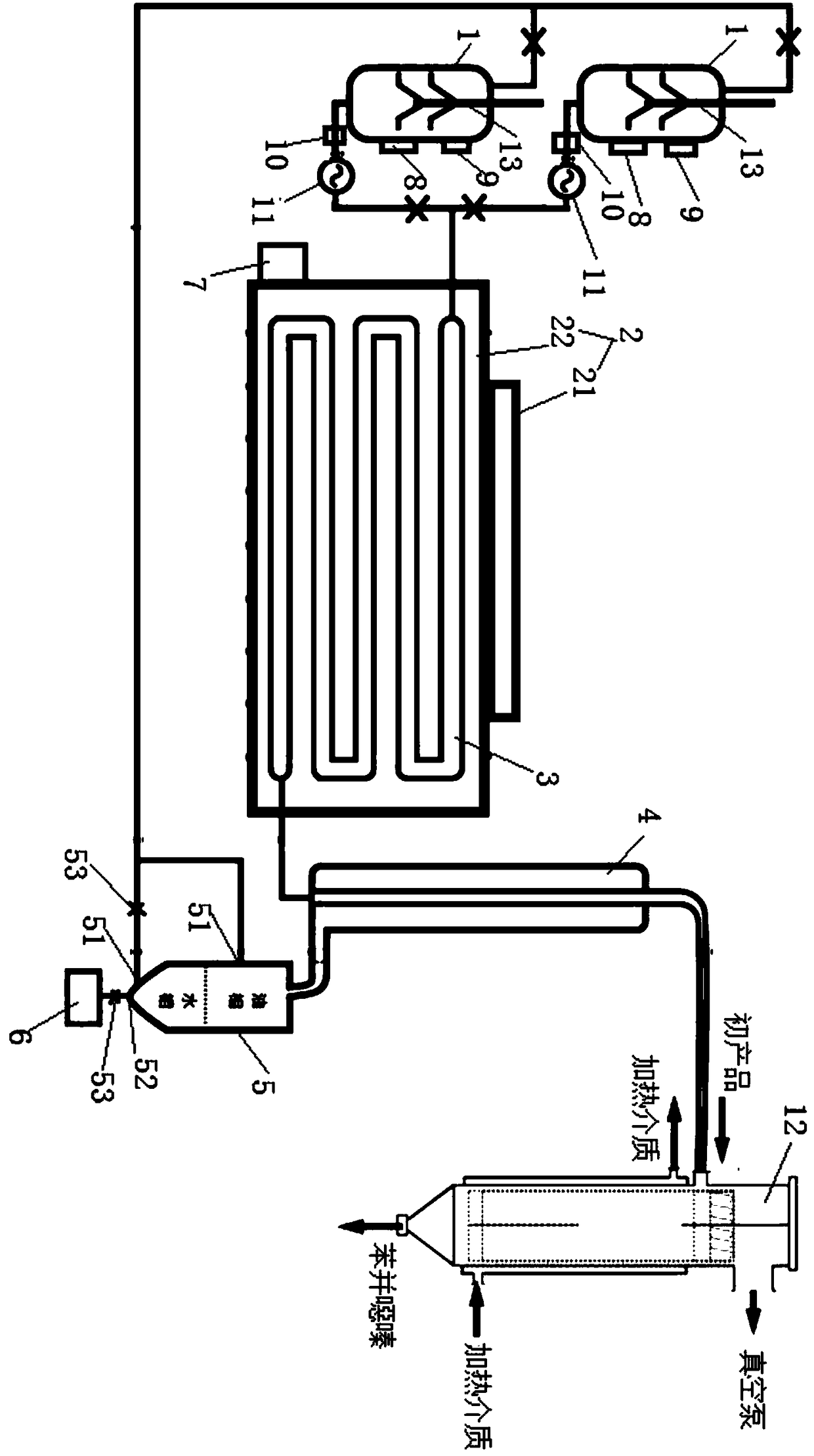

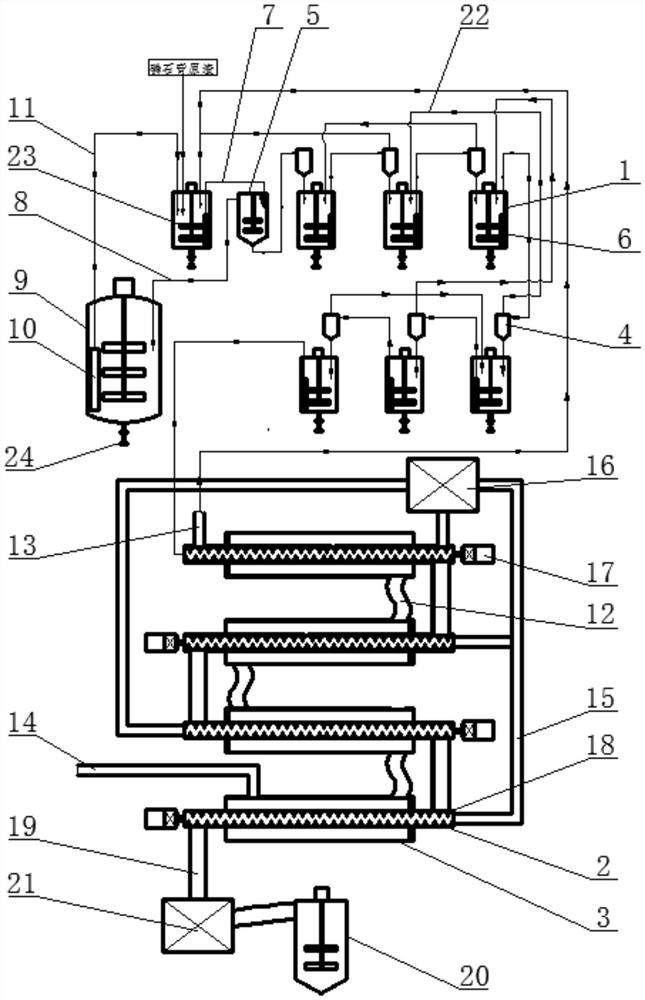

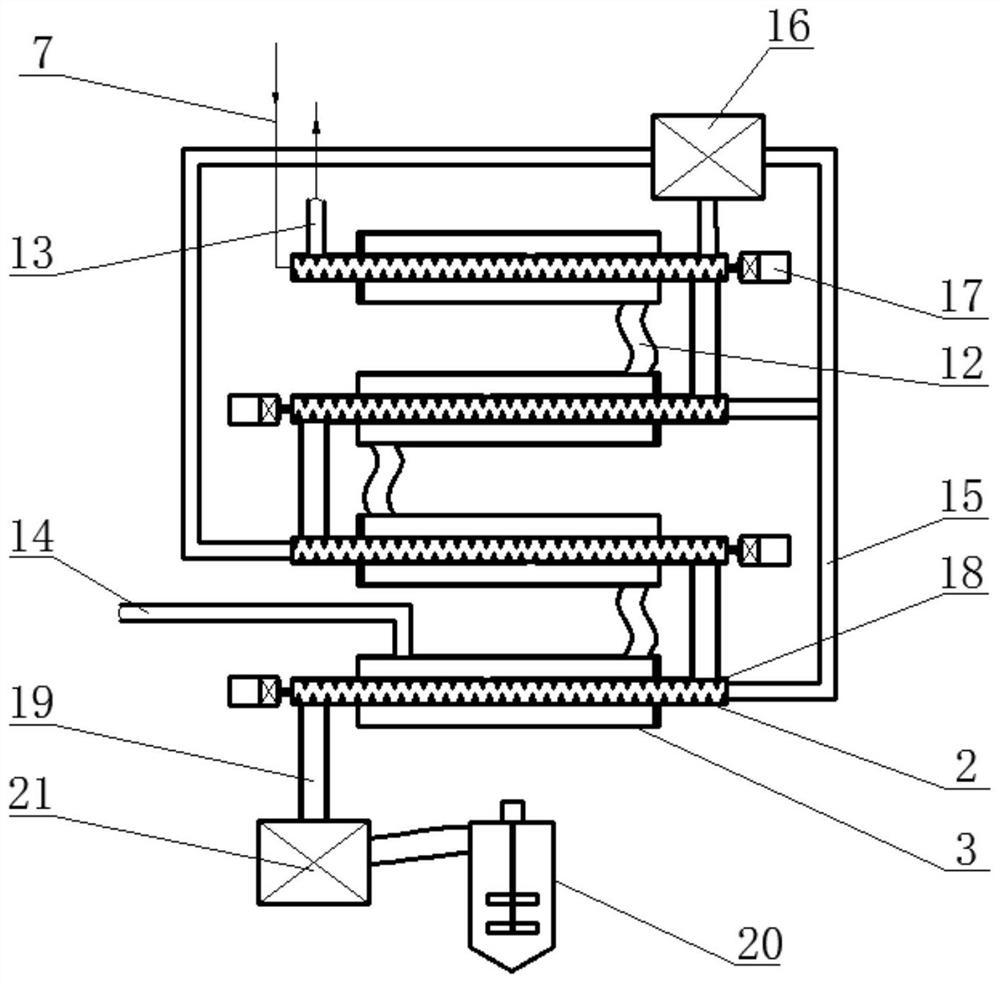

Continuous benzoxazine preparation device and method

The invention discloses a continuous benzoxazine preparation device and method. The device comprises at least two material mixing tanks, a microwave heating device, a tubular reactor, a ceramic membrane separator, an oil-water separator, a scraper film evaporator, a wastewater tank and a controller. Each material mixing tank is provided with a liquid level meter and a buzzer. The method includes:starting microwave heating, pumping mixed reaction liquid in one of the material mixing tank into the tubular reactor, stopping an infusion pump in operation when the liquid level in the tank reachesa lowest value and the corresponding buzzer alarms, and starting the other infusion pump to continue delivering the mixed reaction liquid into the tubular reactor to enable the reaction liquid to continuously enter the tubular reactor; pumping a material after reaction into the ceramic membrane separator, separating to obtain a primary benzoxazine product, pumping into the scraper film evaporator,and purifying to obtain benzoxazine. By continuous reaction, the method has advantages of short reaction time, high yield, high production speed, narrowness in benzoxazine molecular weight distribution and high purity.

Owner:成都科宜高分子科技有限公司

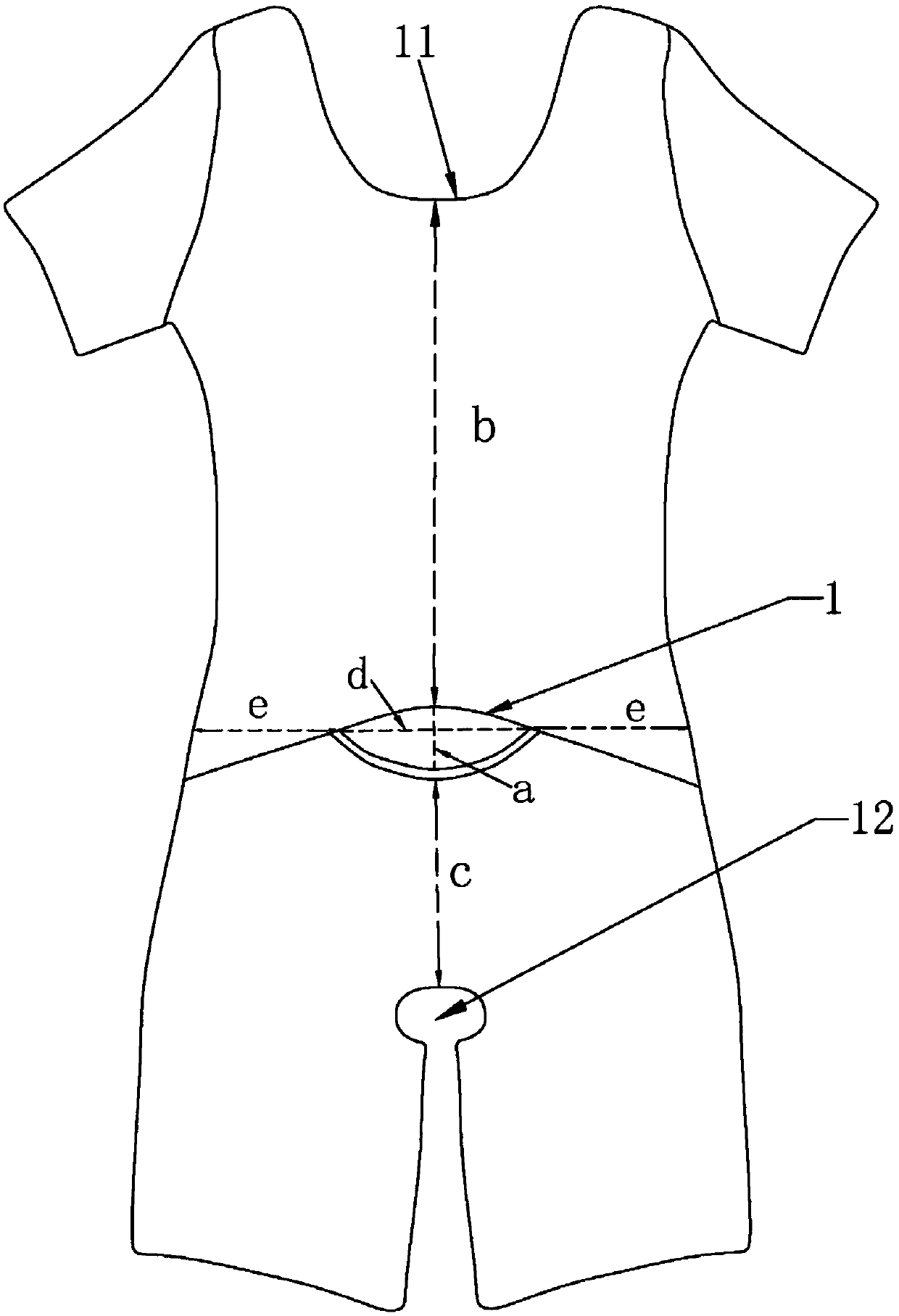

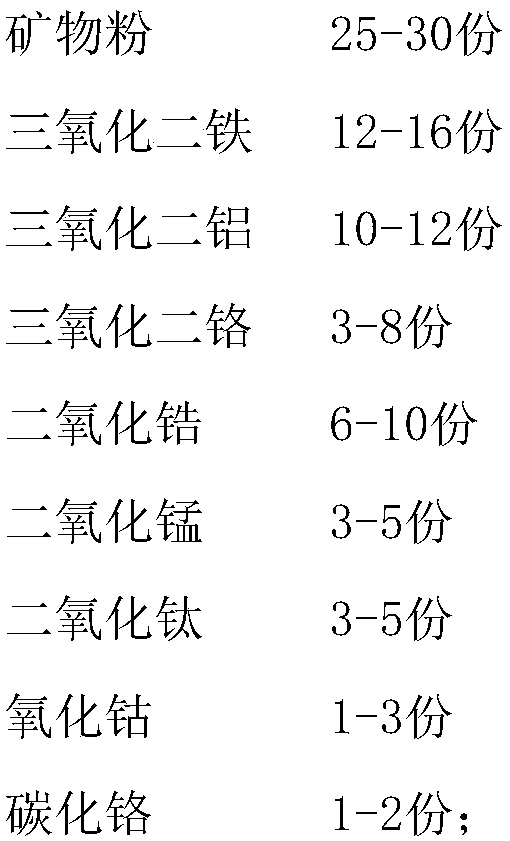

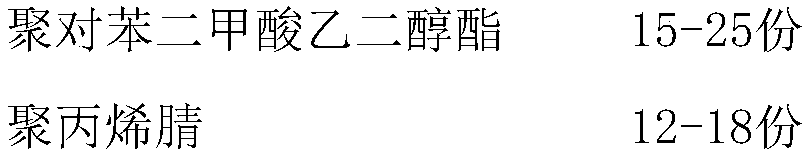

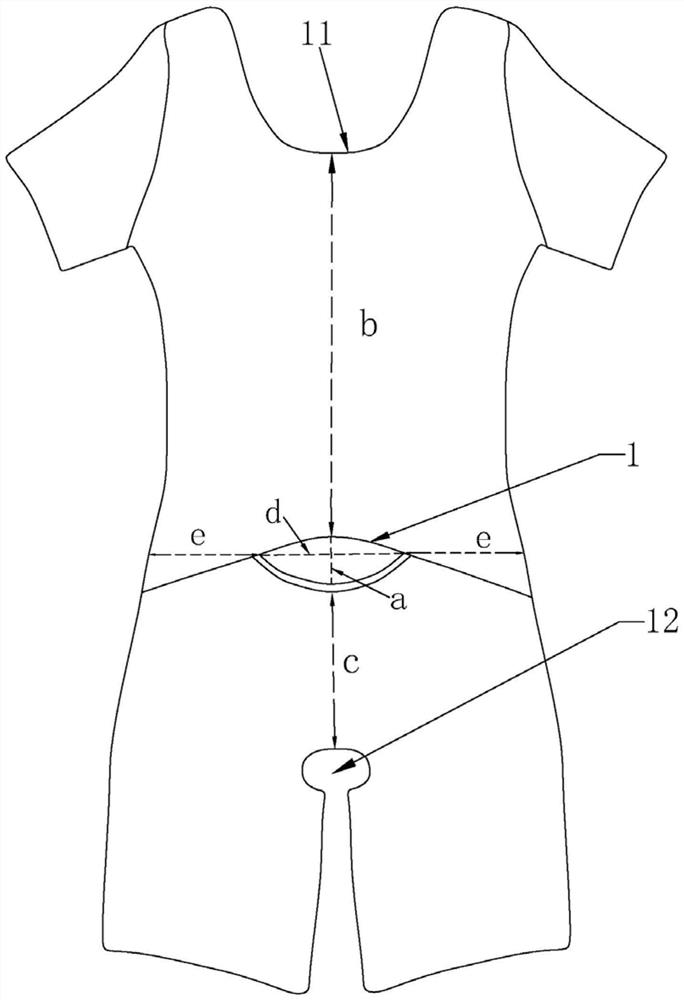

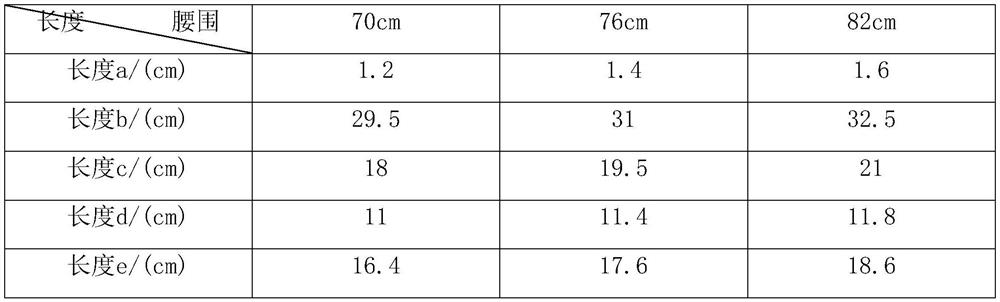

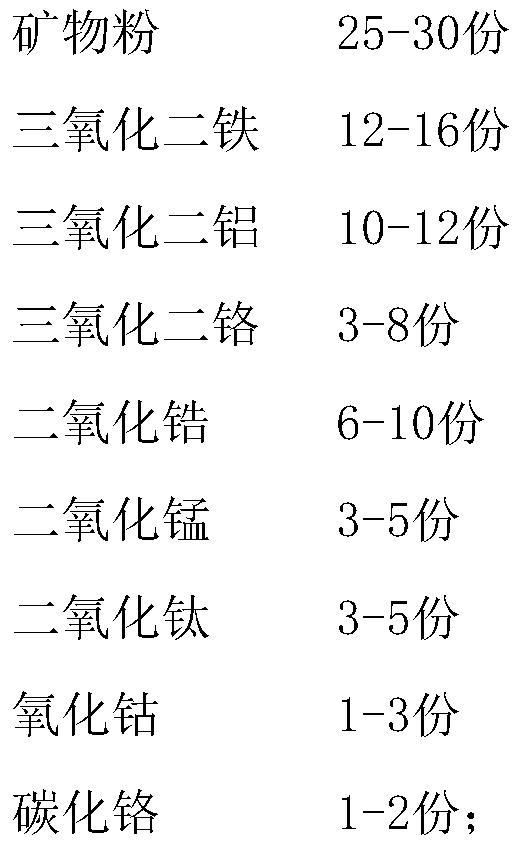

Far infrared seamless corset

ActiveCN109090720AImprove stabilityImprove spinnabilityElectroconductive/antistatic filament manufactureGirdlesFiberLength wave

The invention relates to the technical field of corsets, in particular to a far infrared seamless corset. The far infrared seamless corset is formed by seamless weaving of far infrared fiber. The farinfrared fiber is obtained by far infrared master batches, and the far infrared master batches are a mixture formed by far infrared mixed powder, a composite polymer and auxiliaries with the weight ratio being 4-8:100:0.5-2. The far infrared seamless corset is prepared by weaving far infrared fiber, far infrared ray is released, the mixing ratio of the far infrared fiber far infrared mixed powder,the composite polymer and a polymerization inhibitor is strictly controlled, the released far infrared wavelength is matched with the wavelength range of the human body, the absorption function of the human body is good, the far infrared fiber achieves the antibacterial, heat preservation and healthcare effects, and the effects of eliminating fatigue, promoting blood circulation, dispelling coldness, improving immunity and beautifying the features and achieving skin protection are achieved.

Owner:HONGJI UNDERWEAR CO LTD

Web-forming section and method for manufacturing multi-layer web

InactiveUS7988825B2InhibitionIncreased formationNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFiber layer

A web-forming section of a paper or board machine has a first web-forming unit with a first fiber layer (W1) formed on a first wire (10); a second web-forming unit with a second fiber layer (W2) formed on a second wire (30); and a couch shoe (39) over a curved deck (40) of which the fiber layers (W1, W2) are guided for joining them together. The second fiber layer (W2) is brought to the couch shoe (39) at an angle (α) of less than 20°, advantageously less than 15° in relation to the approach direction of the first fiber layer (W1). The couch shoe (39) is provided with underpressure and the radius of curvature of its deck (40) is usually larger than the radius of curvature of a guide roll (38) preceding it. By the couch shoe, the fiber layers can be joined together wetter than usual.

Owner:VALMET TECH INC

Heat dissipation type building material production equipment with good stirring effect

InactiveCN110605041AAchieve cross flowAvoid damageRotary stirring mixersTransportation and packagingDrive shaftEngineering

The invention relates to heat dissipation type building material production equipment with a good stirring effect. The stirrer comprises a main body, a sealing cover, a protective cover, a discharge pipe, a driving motor, a transmission shaft and at least two first stirring rods, wherein the main body is cylindrical in shape; the sealing cover covers the top of the main body; the discharge pipe isarranged at the bottom of the main body; the protective cover is arranged at the top of the sealing cover; the transmission shaft and the main body are coaxially arranged; the driving motor is fixedon the inner wall of the protective cover; the driving motor is in transmission connection with the top end of a transmission shaft; the transmission shaft penetrates through the sealing cover and isin sliding and sealed connection with the sealing cover; according to the production equipment, the function of stirring raw materials is achieved through the auxiliary mechanism, in addition, the function of dissipating heat of the driving motor is achieved through the heat dissipation mechanism, and damage caused by overheating of the driving motor is avoided.

Owner:深圳市群卜鸿科技有限公司

Normal-pressure removing method of ceramic core in aero-engine titanium alloy casting

ActiveCN111390143APrevent settling and coagulationStop dirtFoundry mouldsFoundry coresCitric acidTitanium alloy

The invention relates to a normal-pressure removing method of a ceramic core in an aero-engine titanium alloy casting. The method comprises the steps that: (1) preparation of core removing liquid: thecore removing liquid contains the following chemical components in percentage by mass: 10-40% of NaOH or KOH or a mixed solution thereof, 3-5% of a penetrating agent, 3-5% of a dispersing agent, 3-5%of an auxiliary, and the balance of water; (2) ultrasonic and heating assisted normal-pressure core removal: a titanium alloy casting to be treated is put in the core removing liquid in step (1), thetemperature of the core removing liquid is 70-90 DEG C, and ultrasonic waves are intermittently applied; and (3) acid liquid neutralization and cleaning: the titanium alloy casting in step (2) is putin a 0.01 M dilute hydrochloric acid or citric acid solution accompanied with compressed air stirring for 20-40 minutes, and then, the titanium alloy casting is taken out and put in clear water to clean by 10-30 minutes. The normal-pressure removing method has the advantages of low cost of needed raw materials, simple process flow, implementation of the removing process under a normal pressure and low energy loss.

Owner:DONGGUAN FUXING DETERGENT TECH

Electromagnetic drying barrel of pulp filament machine

ActiveCN104990376AAnti-scald threadIntensified movementDrying machines with non-progressive movementsHeating arrangementRadiationSurface layer

Owner:安徽省迪盛织造整理有限公司

Multifunctional mixing equipment used for thermal insulation coating

PendingCN108525570AUniform temperatureWell mixedShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionThermal insulation

The invention belongs to the field of paint stirring mixing equipment, and discloses a multifunctional mixing equipment used for thermal insulation coating. The multifunctional mixing equipment used for thermal insulation coating comprises a tank body; a stirring shaft is rotatingly arranged in the tank body; the tank body is connected with a hot air pipe; the tank body is provided with a bar shaped hole; the hot air pipe and the bar shaped hole are connected through a joint; the joint is slidingly arranged in the bar shaped hole, and is connected with a reciprocating mechanism; the reciprocating mechanism comprises a rotating wheel arranged outside the tank body; an eccentric part of the rotating wheel is rotatingly connected with a tooth bar; the tooth bar is provided with a slide groovealong the length direction of the tooth bar; a slide block is slidingly arranged in the slide groove; the slide block is fixedly connected with the joint; the external side of the rotating wheel is provided with a gear engaging with the tooth bar. The multifunctional mixing equipment is capable of solving a problem in the prior art that the position of an air inlet of a conventional mixing tank is fixed, so that coating temperature is nonuniform.

Owner:重庆阿罗科技有限公司

Fine grinding device for refractory material production

The invention discloses a fine grinding device for refractory material production, and relates to the technical field of refractory material production. In order to solve the problem that a feeding area of an existing device is prone to being blocked, the fine grinding device for refractory material production specifically comprises a bottom plate, a support is welded to the outer wall of the top of the bottom plate, a bottom shell is connected to the outer wall of one side of the support through bolts, a grinding component is connected to the outer wall of the top of the bottom shell through bolts, and a material guide component is fixedly connected to the outer wall of the top of the grinding component. According to the fine grinding device for refractory material production, by arranging the feeding component, an anti-blocking motor is started, and two shaft sleeves are driven to rotate through meshing of an external gear, so that a first fluctuation shell and a second fluctuation shell are driven to rotate relatively; the stirring effect on materials can be achieved while the materials are pushed to fall, so that the materials in a middle cover are prevented from being blocked; and when the first fluctuation shell and the second fluctuation shell rotate, a scraping wheel and a shifting wheel rotate along with the first fluctuation shell and the second fluctuation shell in the stopping state of a built-in motor, so that the materials are grabbed to be pushed, and passing of the materials can be accelerated.

Owner:大石桥市三强耐火材料有限公司

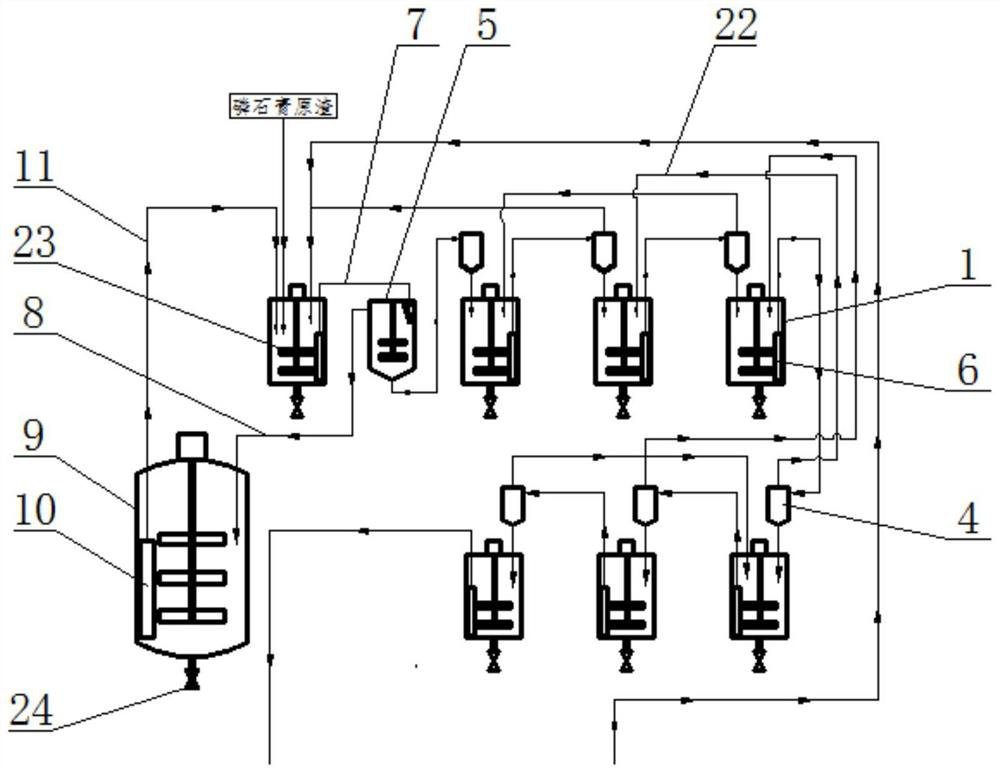

Full-cycle comprehensive utilization integrated complete production line for ardealite and by-products of ardealite

The invention provides a phosphogypsum and by-product full-cycle comprehensive utilization integrated set production line, which comprises purification tanks, calcining cylinders and a heat exchange cylinder, the calcining cylinders are connected in series end to end, a solid-liquid separator is further arranged between two adjacent purification tanks, a thickener is further arranged between the first purification tank and the first solid-liquid separator, and the other solid-liquid separator is arranged between the second purification tank and the second solid-liquid separator. A slurry pump is arranged in the purification tank, the slurry pump respectively extends into the thickener and the next solid-liquid separator through feeding pipes and is connected with the head end of the first calcining cylinder, the upper part of the thickener extends into the synthesis tower through a purification liquid pipe, a reflux pump is arranged in the synthesis tower and is connected with a reflux water pipe, the first heat exchange cylinder is further connected with a steam condensing pipe, and the steam condensing pipe is connected with the condensing pipe. And the tail end of the backflow water pipe and the tail end of the steam condensing pipe extend into the first purification tank. By adopting the technical scheme provided by the invention, by-products such as purified liquid, steam condensate and the like generated in the treatment process of the industrial gypsum raw slag are reasonably and effectively recycled, so that the effective utilization rate of resources is improved, and the pollution to the environment is avoided.

Owner:GUIZHOU LANTU NEW MATERIALS

Preparation method of high-viscosity high-strength raw lacquer

InactiveCN109971347AIncrease crosslink densityImprove mechanical propertiesNatural resin coatingsAluminium saltsChemistry

The invention discloses a preparation method of high viscosity high strength raw lacquer, and belongs to the technical field of paint preparation. The preparation method comprises the steps: performing drying, mixing and grinding on wood chips and straw firstly, then performing immersion in hydrochloric acid for a reaction after grinding so as to prepare mixed slurry, then performing high-temperature high-pressure treatment on the mixed slurry so as to obtain a reaction hydrolyzate, then putting the reaction hydrolyzate and a biogas liquid into a fermentation tank for fermentation so as to obtain a fermented product, then performing microwave treatment on the fermented product, adding aluminum sulfate after microwave treatment, performing mixing and stirring, then performing concentrationdrying after stirring so as to obtain a dried product, putting the dried product and graphite sheets into a sulfuric acid solution, performing even stirring, then adding potassium permanganate for a reaction, performing filtration after the reaction so as to obtain a filter cake, and finally performing stirring and mixing on the filter cake, a raw lacquer liquid and other aids so as to obtain thehigh-viscosity high-strength raw lacquer.

Owner:常州三伊化工有限公司

Domestic waste treatment device

ActiveCN106524169BActivation energyIntensified movementTransportation and packagingSolid waste disposalEngineeringOxygen

The invention relates to the technical field of environmental protection devices, and provides a domestic garbage treatment device, which includes a furnace body, several magnetization devices and air intake devices. Each magnetization device is arranged on the furnace body, and the air intake device is inserted into the furnace body from the outside. The domestic waste treatment device provided by the present invention utilizes several magnetization devices arranged on the furnace body to form a magnetic field environment simulating the interior of the earth in the furnace body, and can magnetize oxygen, other gases and solid domestic waste in the furnace body, so that The energy required to decompose solid waste is greatly reduced, that is, the entire digestion process does not need to provide an additional energy source, so it is more environmentally friendly and energy-saving.

Owner:广东熠森能环保科技有限公司

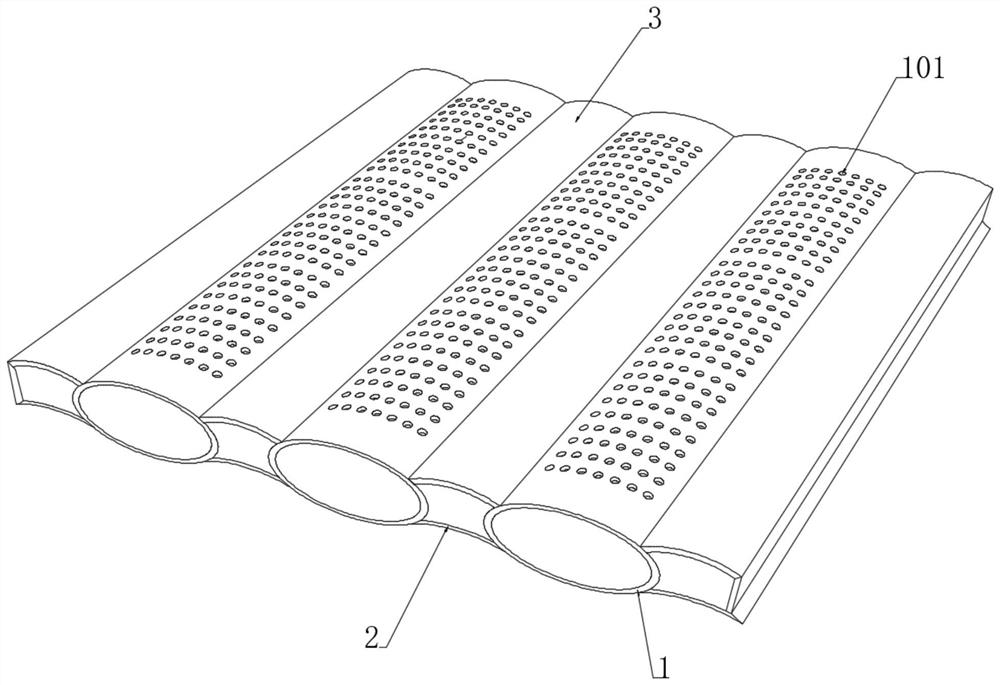

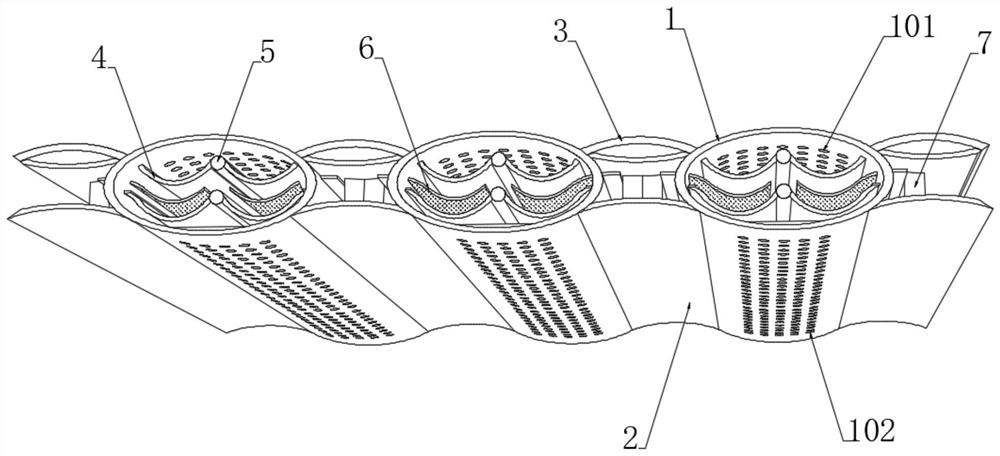

Particle micro-vibration type filter layer based on PP material

ActiveCN113277576AImprove aggregate fluidityImprove filtering effectFatty/oily/floating substances removal devicesSpecific water treatment objectivesPhysical chemistryWastewater

The invention discloses a particle micro-vibration type filter layer based on a PP material, and belongs to the technical field of PP cotton materials. A plurality of PP filter pipes are horizontally distributed to form a filter structure; the plurality of PP filter pipes distribute separate filtrate to improve the aggregation fluidity of wastewater; two heat conduction filtrate layers are vertically distributed in each PP filter pipe; wastewater is guided into the PP filter pipes through liquid inlet holes and then is filtered layer by layer through the two heat-conducting filtrate layers and purification layers located at the bottoms of the heat-conducting filtrate layers. Compared with a single-layer filter layer with a certain thickness in the prior art, the particle micro-vibration type filter layer enlarges the filter area, reserves a filter buffer space and can be matched with a heating environment to improve the filter effect of the wastewater; in addition, a particle vibration sheet is arranged between the two heat-conducting filtrate layers, and the particle vibration sheet is matched with a power box, so that molecular movement of the wastewater flowing through an upper PP filter cotton layer and a lower PP filter cotton layer is intensified, a layer of condensed particles in the wastewater are effectively crushed, the filtering effect is improved, and blockage is prevented.

Owner:广州市艾瑞空气净化设备有限公司

Modified asphalt concrete for purifying air

The invention discloses modified asphalt concrete for purifying air, which comprises traditional asphalt concrete and tourmaline, wherein the use quantity of the tourmaline is 10-40% of the mass of asphalt in the traditional asphalt concrete, and the tourmaline is tourmaline powder and / or tourmaline anion powder. The modified asphalt concrete has remarkable air purifying effect and can effectively purify NOX (Nitrogen Oxide and Nitrogen Dioxide), HC (Hydrocarbon Compounds), CO (Carbon Monoxide) and other harmful gases exhausted by automobiles. Meanwhile, the modified asphalt concrete has certain effect of absorbing greenhouse gas CO2 (Carbon Dioxide) and can obviously improve road surrounding environment. The modified asphalt concrete has the advantages of excellent pavement performance, simple construction technology and nontoxic and harmless raw materials and has great social benefits in the aspects of improving the application quality of asphalt pavement and protecting the environment.

Owner:CHANGAN UNIV

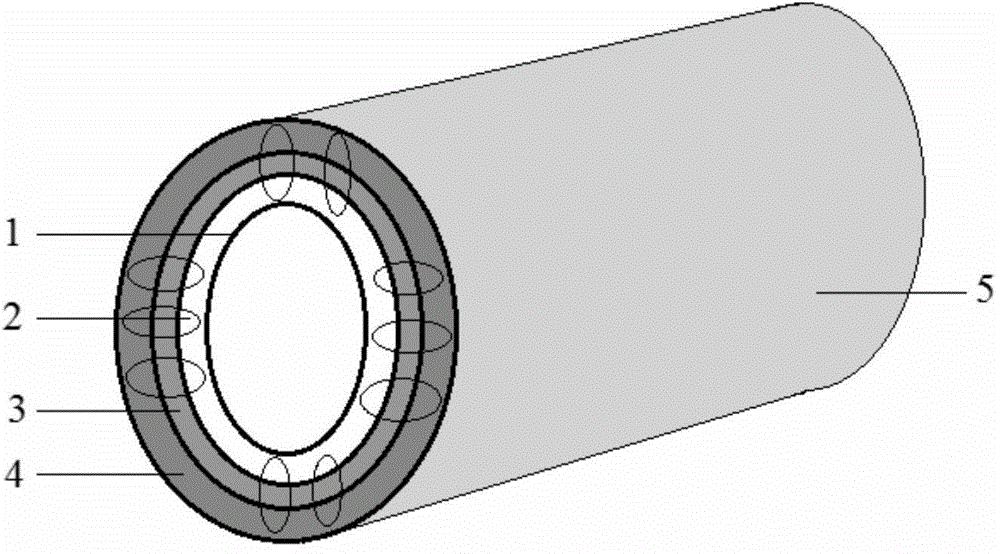

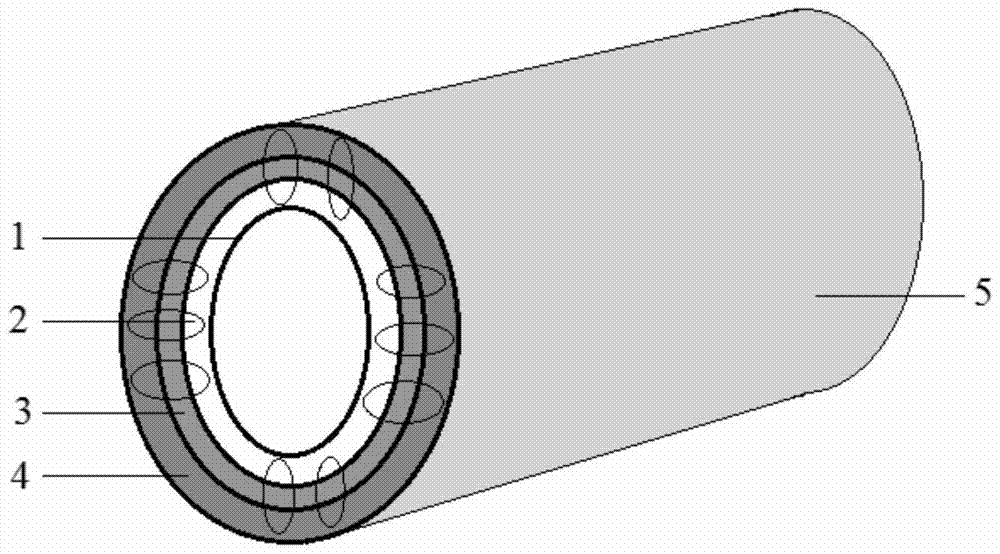

An electromagnetic drying drum for a pulping machine

ActiveCN104990376BAvoid burnsIntensified movementDrying machines with non-progressive movementsHeating arrangementFiberCoated surface

The invention relates to an electromagnetic drying cylinder of a pulping machine, which comprises an electromagnetic coil, an iron ring surrounding the outer circumference of the electromagnetic coil, and a drying cylinder surface layer covering the outer circumference of the iron ring. The invention utilizes the electromagnetic coil to generate eddy current, so that the iron ring on it heats up to heat and dry the pulp; and it can start and stop with the pulp machine, and stop heating in time when an emergency stop is required, effectively preventing it from scalding the silk ; At the same time, the electromagnetic coil radiates to the water molecules in the water on the pulp, which can intensify the movement of water molecules, further increase the temperature, and improve the drying effect.

Owner:涡阳量子信息科技有限公司

Unpowered magnetic suspension simulated ecological trash processing device

PendingCN107199233AEasy to cleanSave energySolid waste disposalTransportation and packagingDecompositionHollow cylinder

The invention belongs to the technical field of trash processing devices, and particularly relates to an unpowered magnetic suspension simulated ecological trash processing device. The unpowered magnetic suspension simulated ecological trash processing device comprises a box body and a furnace chamber in the box body. A screening plate is arranged at the bottom of the furnace chamber and divides the furnace chamber into a trash low-temperature processing cavity located on the upper portion and a bottom ash cavity located on the lower portion. Multiple hollow cylinders which are vertically distributed are arranged in the furnace chamber. Magnetic suspension generators are arranged in the hollow cylinders. Multiple magnetic inner plates are arranged at the positions, close to the box body, in the furnace chamber. A magnetic field is formed between the magnetic suspension generators and the magnetic inner plates. The screening plate is arranged at the bottom of the furnace chamber, ash generated in the trash low-temperature processing cavity can enter the bottom ash cavity, and the ash can be conveniently removed. Air can be magnetized through the magnetic field, to-be-processed trash can also be directly or indirectly magnetized at the same time, energy required for trash decomposition is reduced, and therefore generation of harmful gas can be prevented, and energy which is used is saved.

Owner:周丕雕

A kind of atmospheric pressure removal method of the ceramic core in the titanium alloy casting of aero-engine

ActiveCN111390143BIntensify chalkingIntensified dissolutionFoundry mouldsFoundry coresAviationUllage

The invention relates to a method for removing a ceramic core in an aero-engine titanium alloy casting under normal pressure, comprising the following steps: Step 1, configuration of a core removal liquid: the core removal liquid contains the following chemical components in mass fractions: 10 %~40% NaOH or KOH or their mixed solution, 3%~5% penetrating agent, 3%~5% dispersant, 3%~5% auxiliary agent, and the rest is water; step 2, ultrasonication, heating Auxiliary normal pressure core removal: Put the titanium alloy casting to be treated into the core removal liquid in step 1, the temperature of the core removal liquid is 70 ℃ ~ 90 ℃, and apply ultrasonic waves intermittently; step 3, acid solution neutralization and cleaning, Place the titanium alloy casting in step 2 in 0.01M dilute hydrochloric acid or citric acid solution stirred with compressed air, and after standing for 20-40 minutes, take out the titanium alloy casting and wash it in clean water for 10-30 minutes. The normal pressure removal method of the present invention has the following advantages: the required raw material price is low, the process flow is simple, the removal process is carried out under normal pressure and the energy loss is small.

Owner:DONGGUAN FUXING DETERGENT TECH

High-efficiency healthy environment-friendly dyeing method for reed stalks

InactiveCN108818842AEasy to useIncrease the gapElectric wood treatmentWood treatment detailsPolyvinyl alcoholResource utilization

The invention especially relates to a high-efficiency healthy environment-friendly dyeing method for reed stalks, belonging to the technical field of dyeing. The method comprises the following concrete steps: (1) immersing the reed stalks in an aqueous solution of maltitol, picking up the reed stalks, carrying out draining until no water drop drips, putting the reed stalks into a freezer for freezing treatment, taking out the reed stalks, treating the reed stalks with constant-temperature steam, then taking out the reed stalks, and carrying out cooling at room temperature so as to obtain pretreated reed stalks; and (2) subjecting the pretreated reed stalks to electric field treatment, immersing the reed stalks in a dyeing agent, taking out the reed stalks, carrying out draining until no water drop drips, and then drying the reed stalks. The dyeing agent is prepared from the following raw materials: fresh rose petals, fresh mint leaves, fresh violet petals, fresh rhododendron petals, cellulase, nanometer calcium carbonate, nanometer silica, goat milk, taurine, polyvinyl alcohol, ethyl acetate and water. The method provided by the invention effectively improves a dyeing rate and dyeing stability, allows the dyed reed stalks to have strong anti-fading ability, effectively enhances the strength and toughness of reed stalks, improves the usage performance of the reed stalks, and increases the utilization rate of resources.

Owner:阜南县勤艺工艺品有限公司

Gearbox parts processing device

ActiveCN108554715BEasy to operateRealize automatic full paintingLiquid surface applicatorsCoatingsReciprocating motionEngineering

The invention relates to the field of production and processing of gears and discloses a device for processing gearbox parts. The device comprises a paint tank; a vertically arranged screw rod pair isarranged in the paint tank; the screw rod pair is rotatably connected with the tank wall of the paint tank; the lower end of the screw rod pair is connected with a fixing disk for fixing a gear; theround side part of the fixing disk is connected with a plurality of lifting ropes which are distributed uniformly; the lifting ropes are connected with lifting balls; screw rods matched with the screwrod pair penetrate through the screw rod pair; and the screw rods are connected with a reciprocating motion mechanism for controlling the screw rods to do straight reciprocating motions. The device can realize comprehensive and automatic painting of the gear and does not need hands to turn over.

Owner:重庆市大足区川江金属制品厂

Nanometer anhydrous cooling liquid for construction machinery equipment

InactiveCN107794006AImprove heat exchange efficiencyReduce pump powerChemical industryHeat-exchange elementsNanofluidChemistry

The invention discloses a nanometer anhydrous cooling liquid for construction machinery equipment. The nanometer anhydrous cooling liquid comprises, by mass, 60 to 80 parts of propylene glycol, 5 to 10 parts of a nano-oxide, 3 to 6 parts of 2-thiobenzothiazole, 4 to 7 parts of triazole toluene, 1 to 5 parts of polyamino acid, 1 to 2 parts of sodium nitrate, 1 to 3 parts of sebacic acid, 0.5 to 2 parts of methyl orthosilicate and 0.2 to 1 part of an organic silicon defoaming agent. Through use of a metal oxide nanofluid having thermal conductivity multiple times higher than that of the conventional fluid cooling medium, the heat exchange capacity of the cooling system is doubled and the property defect of low propylene glycol thermal conductivity is solved. The high boiling point (187 DEG C) of the fluid medium is suitable for long-term continuous operation of the large-power high-load machinery equipment under a high temperature and high pressure. The high heat produced by the construction machinery equipment operation aggravates movement and energy transfer intensity of the oxide nanoparticles so that heat exchange efficiency is improved, the pump power of the cooling system underthe same heat exchange demand is reduced and a service life of the cooling liquid is prolonged.

Owner:NANTONG JIE GAO FURNITURE CO LTD

A decompression drying equipment suitable for the processing of medicinal materials and food materials

ActiveCN107860200BMaintain colorLow boiling pointDrying solid materials without heatDrying machines with progressive movementsBristleUltrasonic sensor

The invention provides decompression drying equipment suitable for processing of medicinal materials and food materials. The decompression drying equipment comprises a drying box, a feeding hopper, areceiving box and a vacuumizing device. A drying device, a collecting block and a lifting device are arranged in the drying box. The drying device comprises a first drying unit and a second drying unit which each comprise a material conveyor belt, an ultrasonic transducer located below the material conveyor belt, a driving motor and an infrared lamp pole located above the material conveyor belt. Amaterial dispersing device is arranged above the first drying unit. Baffles are arranged below the second drying unit, limiting grooves and brush bristles are arranged above the baffles, and the lifting device is located on one side of the drying device. According to the decompression drying equipment, original colors and flavor of the medicinal materials can be completely maintained, and the vacuumizing device is adopted to vacuumize the interior of the drying box so that the medicinal materials can be prevented from being wet again by water vapor while the drying efficiency is improved, andthe drying effect is good.

Owner:安平县森喆金属制品有限公司

A far-infrared seamless shapewear

ActiveCN109090720BImprove stabilityImprove spinnabilityElectroconductive/antistatic filament manufactureGirdlesFiberPolymer science

The invention relates to the technical field of corsets, in particular to a far infrared seamless corset. The far infrared seamless corset is formed by seamless weaving of far infrared fiber. The farinfrared fiber is obtained by far infrared master batches, and the far infrared master batches are a mixture formed by far infrared mixed powder, a composite polymer and auxiliaries with the weight ratio being 4-8:100:0.5-2. The far infrared seamless corset is prepared by weaving far infrared fiber, far infrared ray is released, the mixing ratio of the far infrared fiber far infrared mixed powder,the composite polymer and a polymerization inhibitor is strictly controlled, the released far infrared wavelength is matched with the wavelength range of the human body, the absorption function of the human body is good, the far infrared fiber achieves the antibacterial, heat preservation and healthcare effects, and the effects of eliminating fatigue, promoting blood circulation, dispelling coldness, improving immunity and beautifying the features and achieving skin protection are achieved.

Owner:HONGJI UNDERWEAR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com