Continuous benzoxazine preparation device and method

A benzoxazine and microwave heating device technology, applied in the field of polymer chemistry, can solve the problems of limited production capacity, labor consumption, low production efficiency, etc., and achieves short reaction time, improved reaction speed, and improved productivity and production speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

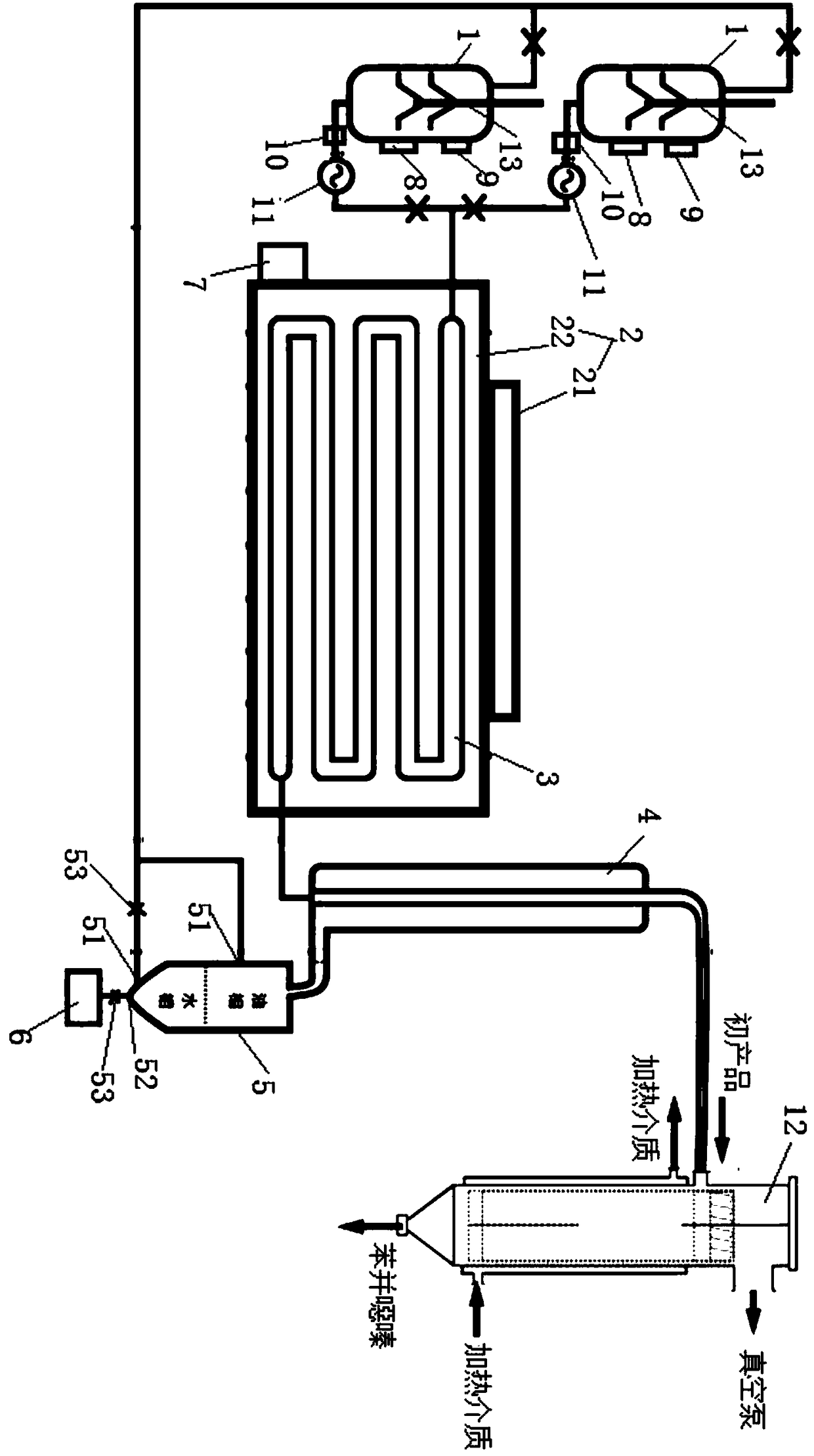

[0034] like figure 1As shown, the device for the continuous preparation of benzoxazine of the present invention has a structural composition comprising: at least two material mixing tanks 1, a microwave heating device 2, a tubular reactor 3, a ceramic membrane separator 4, and an oil-water separator 5 , waste water tank 6, controller 7 and scraper type thin film evaporator 12. Wherein, the liquid level gauge 8 and the buzzer 9 are set on the material mixing tank 1, the controller 7 is connected with the liquid level gauge 8 and the buzzer 9 respectively, and the controller controls the buzzer based on the liquid level information detected by the liquid level gauge. buzzer on or off. Each material mixing tank is provided with an agitator 13 . Each material mixing tank is connected to the feed port of the tubular reactor, and an infusion pump 10 and a flow meter 11 are provided on the connecting pipeline between each material reaction tank and the tubular reactor. The tubular...

Embodiment 2

[0038] The method for preparing benzoxazine by adopting the above-mentioned device for continuously preparing benzoxazine comprises the following steps:

[0039] Step S1, preparation of raw materials: add toluene as a solvent to two material mixing tanks (material mixing tank A and material mixing tank B); then add phenol, formaldehyde and aniline in sequence; the amount of toluene in the material mixing tank accounts for The total mass of all reaction materials is 30%, the mass ratio of phenol, formaldehyde and aniline is 94:60:93, the stirring is started, the raw materials are fully mixed and dissolved in toluene solvent.

[0040] Step S2, turn on the microwave heating device, control the temperature in the heating chamber at 70°C, adjust the flow rate of the material mixing tank A obtained in step S1, and then continuously inject the mixed reaction liquid into the tubular reactor through the infusion pump A; because in this At high temperature, phenol, aldehyde, and amine w...

Embodiment 3

[0047] The method for preparing benzoxazine by means of a device for continuously preparing benzoxazine comprises the steps of:

[0048] Step S1, prepare raw materials: add toluene respectively in two material mixing tanks (material mixing tank A and material mixing tank B) as a solvent; then add bisphenol A, paraformaldehyde and aniline in sequence; the toluene in the material mixing tank The dosage accounts for 30% of the total mass of all reaction materials in the tank, the mass ratio of bisphenol A, paraformaldehyde, and aniline is 228:120:186, start stirring, fully mix the raw materials and dissolve them in toluene solvent.

[0049] Step S2, turn on the microwave heating device, control the temperature in the heating chamber at 75°C, adjust the flow rate of the material mixing tank A obtained in step S1, and then continuously inject the mixed reaction liquid into the tubular reactor through the infusion pump A; because in this At high temperature, phenol, aldehyde, and am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com