Unpowered magnetic suspension simulated ecological trash processing device

A garbage disposal equipment and suspension magnetic levitation technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as difficult control of the combustion process, secondary pollution, easy damage to incineration equipment, etc., to prevent harmful Gas generation, energy saving use, and energy reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better explain the present invention and facilitate understanding, the following describes the present invention in detail through specific embodiments in conjunction with the accompanying drawings.

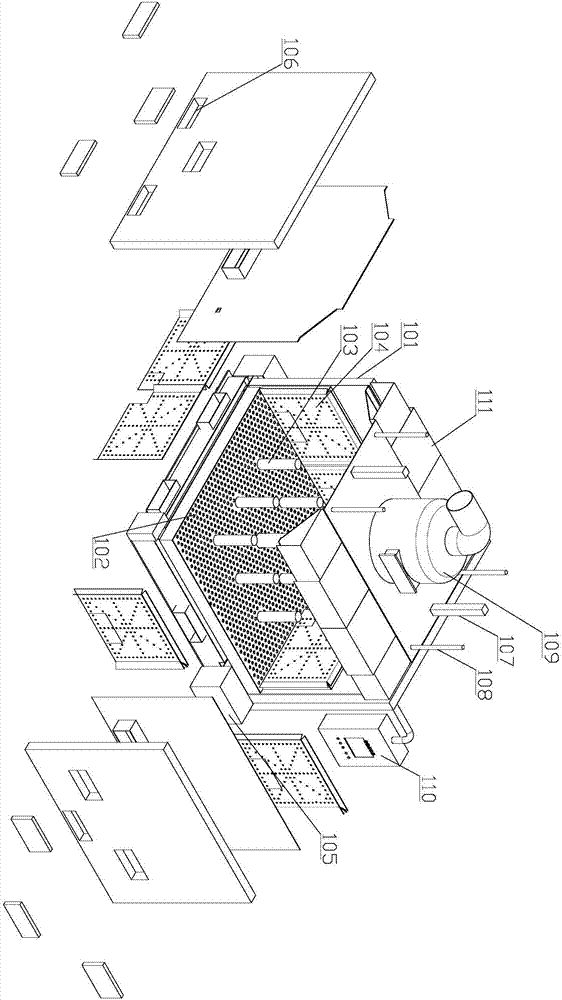

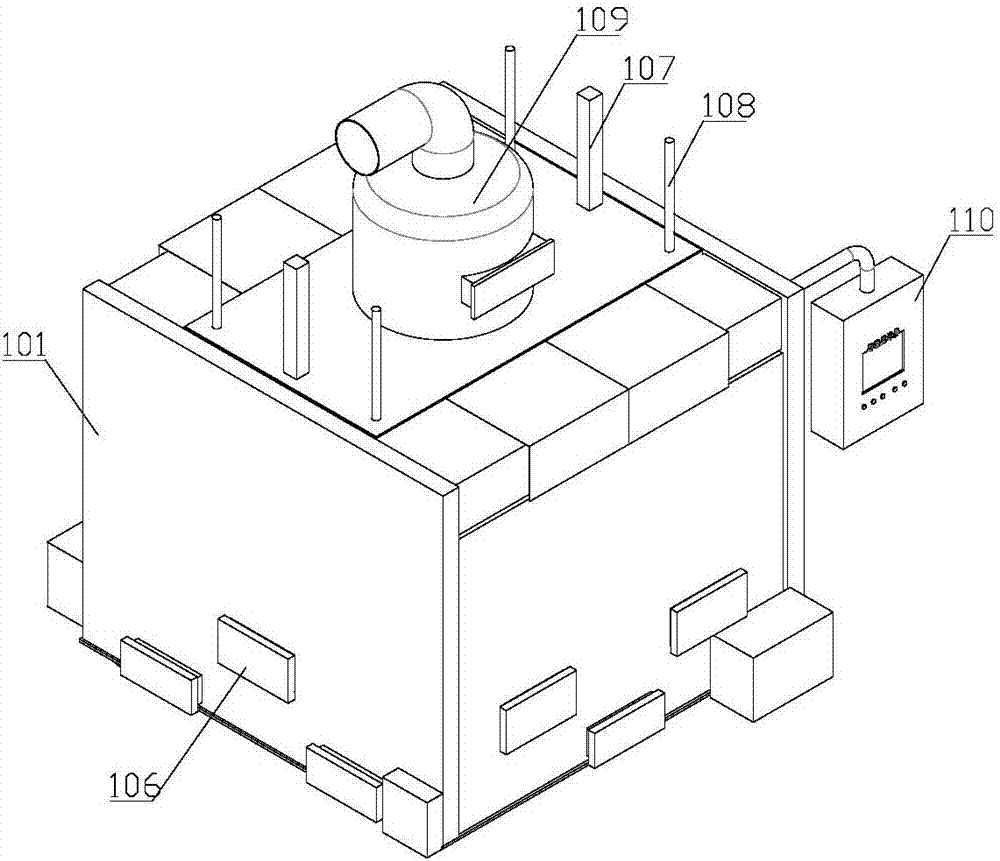

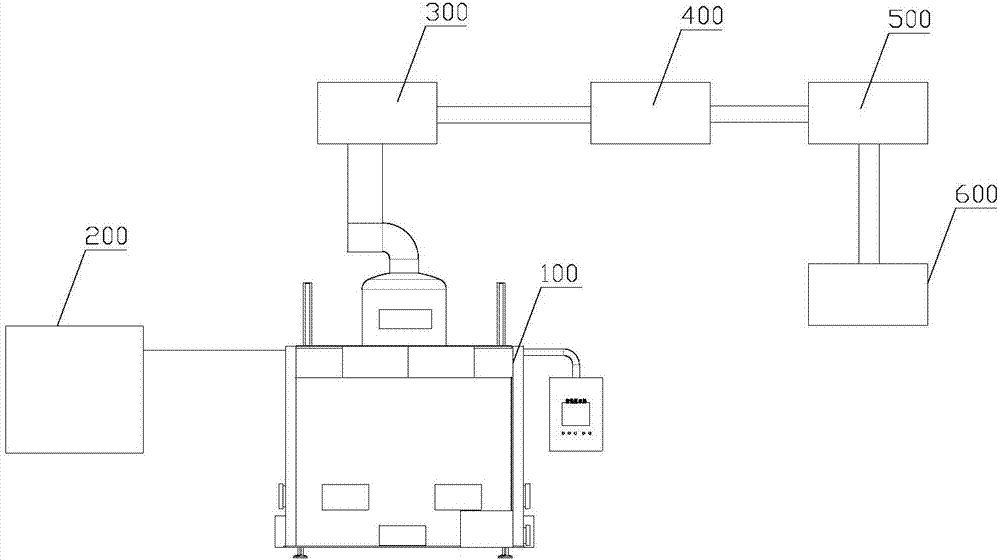

[0035] Such as Figure 1 to Figure 2 As shown, this embodiment provides a non-powered suspension magnetic levitation anti-ecological waste treatment equipment, which includes a box body 101 and a furnace cavity in the box body. The bottom of the furnace cavity is provided with a sieve plate 102, and the sieve plate 102 divides the furnace cavity into The garbage low-temperature treatment chamber at the upper part and the bottom ash chamber at the lower part.

[0036] A plurality of vertically arranged hollow cylinders 103 are arranged in the furnace cavity, and a suspension magnetic levitation generator is arranged in the hollow cylinder 103. A plurality of magnetic inner plates 104, a suspension maglev generator and a A magnetic field is formed between the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com