Preparation method of high-viscosity high-strength raw lacquer

A high-strength, high-viscosity technology, applied in coatings, natural resin coatings, etc., can solve the problems of poor wear resistance, slow curing rate of raw paint, poor viscosity, etc., to increase the contact probability, strengthen the adhesion performance, and improve the viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

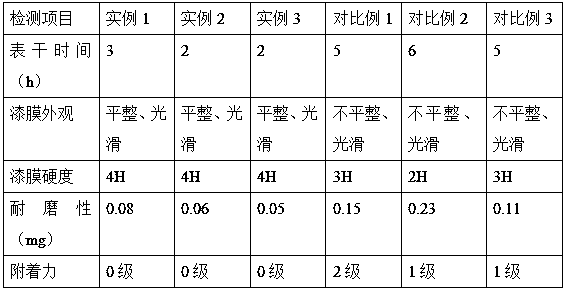

Examples

Embodiment 1

[0032] Preparation of mixed solution:

[0033] Put sawdust and crop straw into an oven at a mass ratio of 3:1, dry at a temperature of 70°C for 5 hours, and put them into a planetary ball mill after drying. Grind for 2 hours to obtain a grinding mixture, put the grinding mixture and hydrochloric acid with a mass fraction of 4% into a beaker at a mass ratio of 1:10, and mix and stir for 45 minutes with a stirring device at a speed of 300 r / min to obtain a mixed slurry;

[0034] Put the above mixed slurry into the reactor, fill the reactor with nitrogen until the pressure in the reactor rises to 1.6MPa, raise the temperature in the reactor to 160°C, and add a mass fraction of 3 ~6% sodium bicarbonate solution adjusts the pH value to neutral to obtain a reaction hydrolyzate, and puts the reaction hydrolyzate and biogas liquid into the fermenter at a mass ratio of 15:1;

[0035] Seal the above-mentioned fermentation tank, place it in a greenhouse with a room temperature of 32°C, ...

Embodiment 2

[0042] Preparation of mixed solution:

[0043] Put sawdust and crop straw into an oven at a mass ratio of 3:1, dry for 5.5 hours at a temperature of 75°C, and put them into a planetary ball mill after drying. Grind for 2.5 hours to obtain a grinding mixture, put the grinding mixture and hydrochloric acid with a mass fraction of 6% into a beaker at a mass ratio of 1:10, and mix and stir for 55 minutes with a stirring device at a speed of 350 r / min to obtain a mixed slurry;

[0044] Put the above mixed slurry into the reactor, fill the reactor with nitrogen until the pressure in the reactor rises to 1.8 MPa, raise the temperature in the reactor to 170°C, and react at constant temperature and pressure for 70 minutes to dropwise add a mass fraction of 5 % of sodium bicarbonate solution to adjust the pH value to neutral to prepare a reaction hydrolyzate, and put the reaction hydrolyzate and biogas liquid into the fermenter at a mass ratio of 15:1;

[0045] Seal the above-mentioned...

Embodiment 3

[0052] Preparation of mixed solution:

[0053] Put sawdust and crop straw into an oven at a mass ratio of 3:1, dry for 6 hours at a temperature of 80°C, and put them into a planetary ball mill after drying at a ball-to-material ratio of 10:1 and a rotational speed of 180r / min. Grind for 3 hours to obtain a grinding mixture, put the grinding mixture and hydrochloric acid with a mass fraction of 8% into a beaker at a mass ratio of 1:10, and mix and stir for 60 minutes with a stirring device at a speed of 400 r / min to obtain a mixed slurry;

[0054] Put the above mixed slurry into the reactor, fill the reactor with nitrogen until the pressure in the reactor rises to 2.0MPa, raise the temperature in the reactor to 180°C, and react at constant temperature and pressure for 80 minutes to dropwise add a mass fraction of 6 % of sodium bicarbonate solution to adjust the pH value to neutral to prepare a reaction hydrolyzate, and put the reaction hydrolyzate and biogas liquid into the fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com