Particle micro-vibration type filter layer based on PP material

A technology of micro-vibration and filter layer, which is applied in the field of PP cotton material, can solve problems such as failure to achieve filter effect, clogging of condensed particles, environmental damage, etc., and achieve the effect of improving aggregation fluidity, improving filter effect, and expanding filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

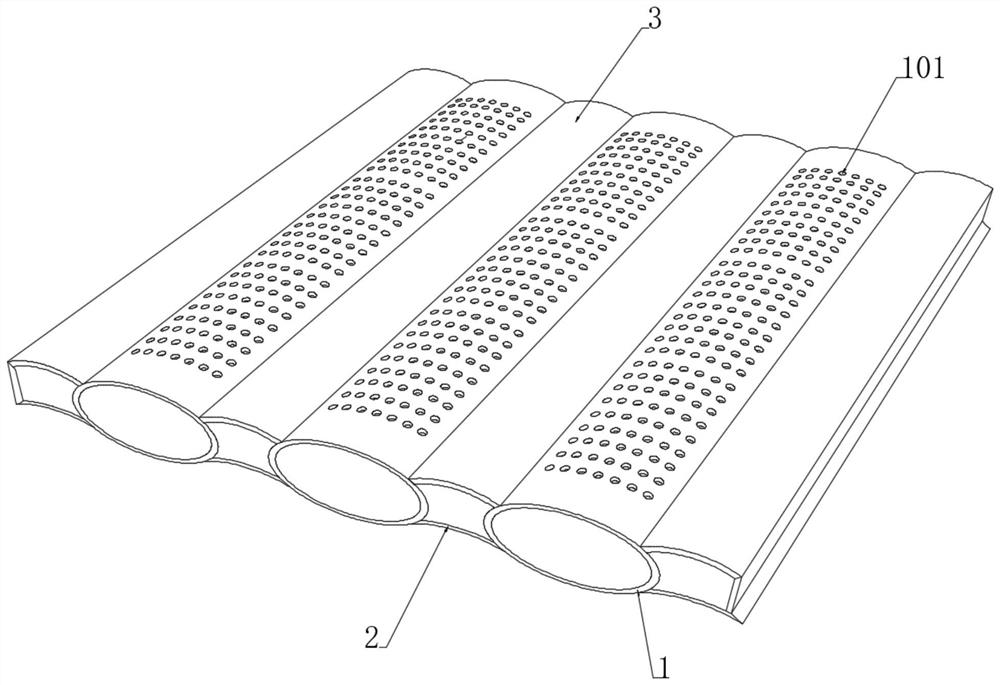

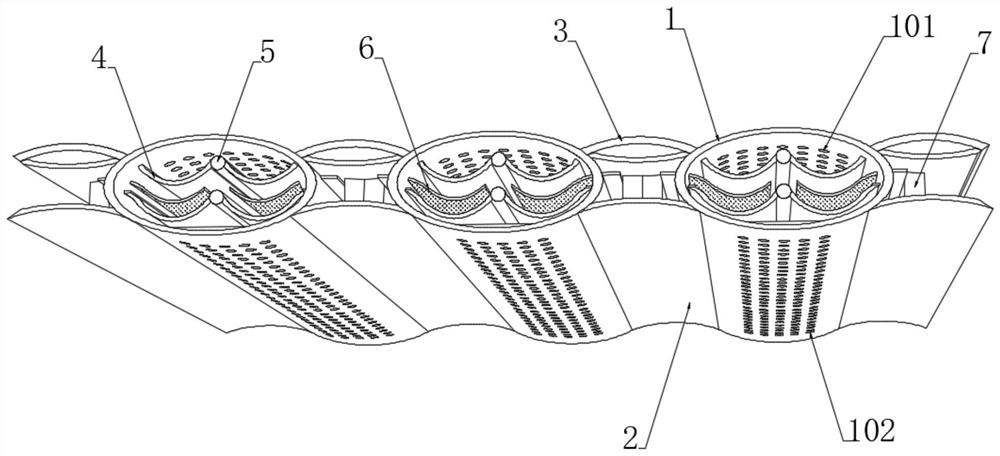

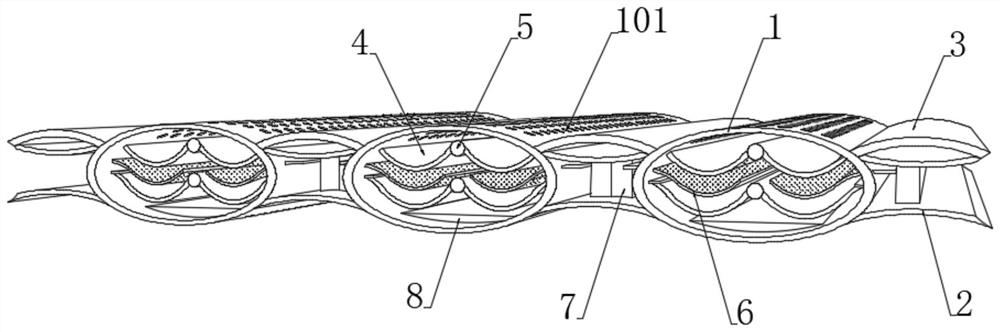

[0041] see Figure 1-2 , a particle micro-vibration filter layer based on PP material, including a plurality of PP filter tubes 1 arranged horizontally, two adjacent PP filter tubes 1 are connected by an arc-shaped connecting frame 2 distributed up and down, and are located at the edge The outer ends of the PP filter tubes 1 on both sides are also equipped with arc-shaped connecting frames 2 distributed up and down. The power drive chamber is formed between the upper and lower two arc-shaped connecting frames 2, and the tops of multiple PP filter tubes 1 are provided with liquid inlet holes. 101, the bottom ends of multiple PP filter tubes 1 are provided with drain holes 102, the front and rear ends of the PP filter tubes 1 and the front and rear ends of the power drive cavity are all embedded with anti-leakage layers, and the particle vibrating plate 6 is connected with the PP filter A sealing gasket is embedded at the junction of the pipe 1, so that the waste water is introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com