Numerical simulation method for cutting process of bar cutter

A numerical simulation and cutting machine technology, which is applied in the field of brick manufacturing, can solve the problems of wasting electric energy consumed by motor idling and reducing the working efficiency of the cutting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with the description of the accompanying drawings, the numerical simulation method of the cutting process of the strip cutter of the present invention is further described:

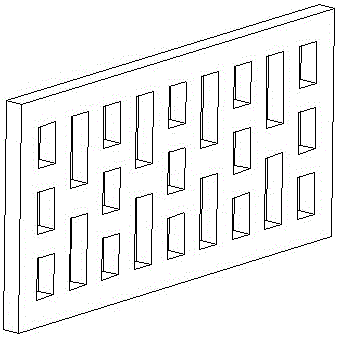

[0023] The first step is to establish and import the model: use Pro / E software to establish the 3D solid model of steel wire and mud strip, save the model as a file in IGES format, and then import it into LS-DYNA respectively, in which the 3D solid model of steel wire and mud strip is cut Models are based on drawings.

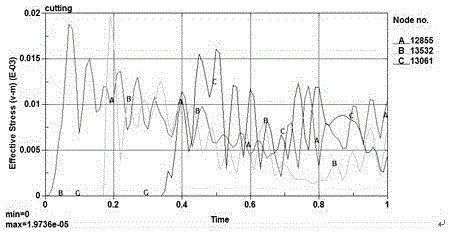

[0024] The second step is to set the material properties: a reasonable material model is the fundamental guarantee for the success of the numerical simulation. The mud strip cutting tool is carbon spring steel wire, and its base material is C36D2. In order to reduce the simulation time, and consider the expected simulation The data are cutting force and cutting power consumption. The rigid body material model Rigid Material is selected, and the material paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com