Pigment red 112 dispersions and preparation method thereof

A dispersion and pigment red technology, applied in the field of pigments, can solve problems such as poor dispersion performance and unstable state, and achieve the effects of improving stability and overcoming poor water solubility and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

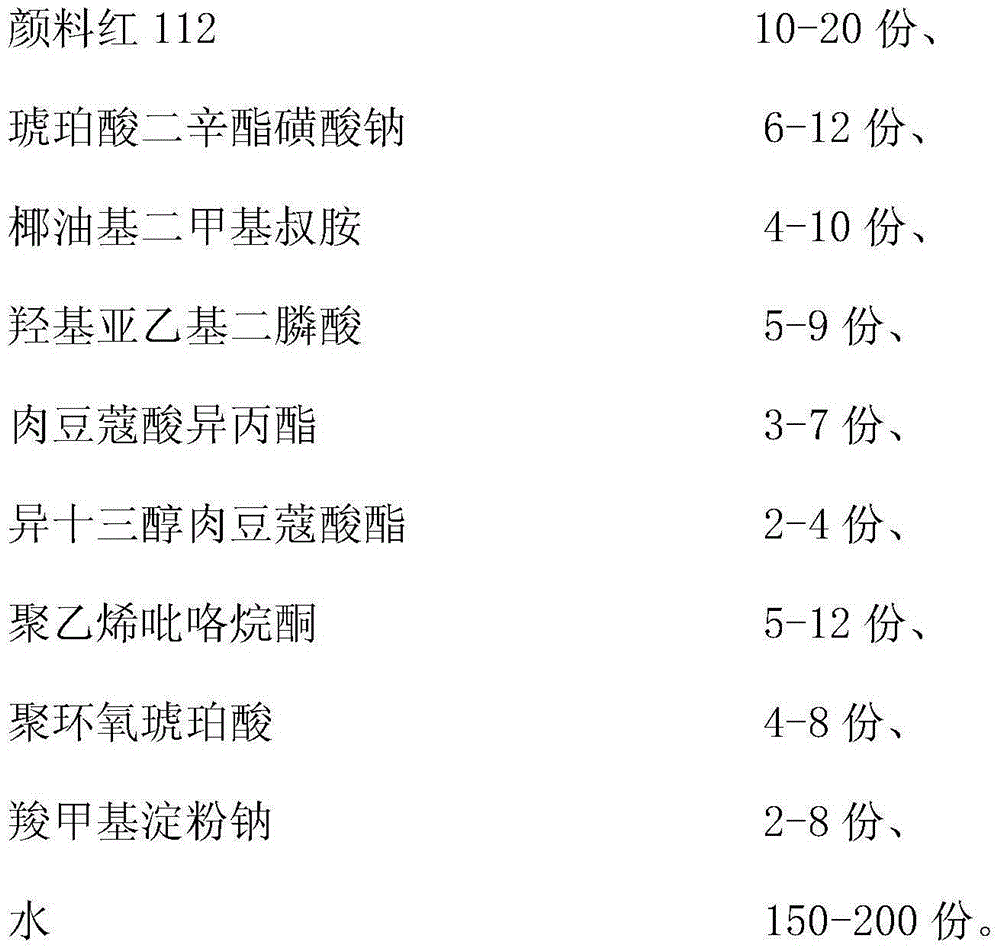

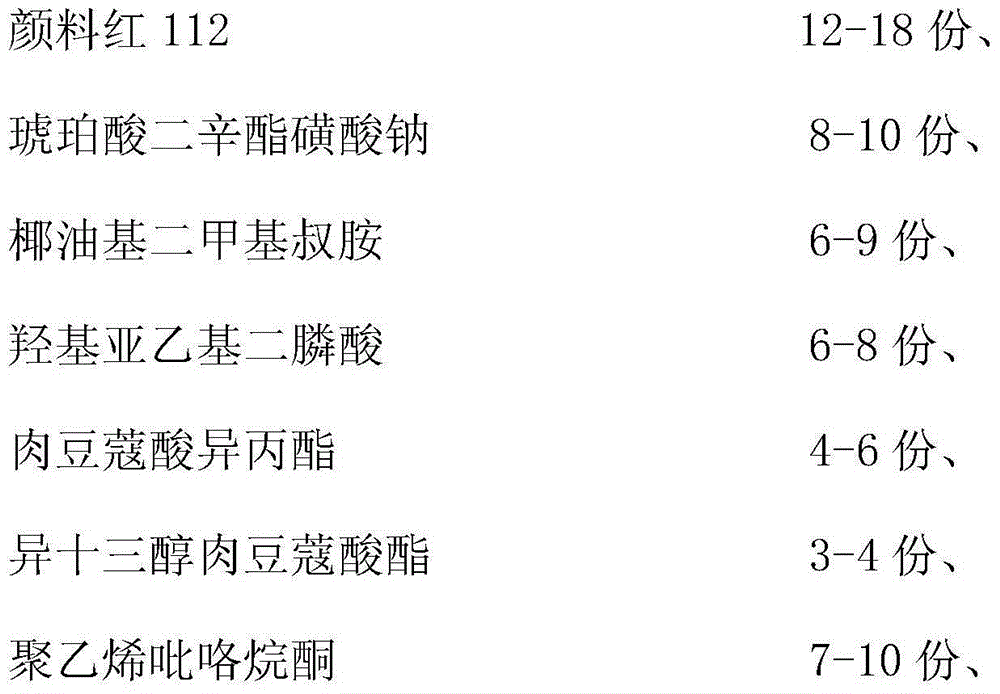

Method used

Image

Examples

Embodiment 1

[0020] (1) Take 20 parts of Pigment Red 112 by weight, 6 parts of dioctyl sodium succinate sulfonate, 10 parts of coco-based dimethyl tertiary amine, 9 parts of hydroxyethylene diphosphonic acid, and isomyristate. 7 parts of propyl ester, the above ingredients are mechanically mixed at a temperature of 70°C, and stirred until uniform; (2) 4 parts of isotridecanol myristate are added to the mixed ingredients of step (1) by weight, 12 parts of polyvinylpyrrolidone, 4 parts of polyepoxysuccinic acid, 8 parts of sodium carboxymethyl starch, 150 parts of water, and then adjust the temperature to 80°C, and then stir until it is uniform; (3) Step (2) After uniformly stirring, the mixed components are cooled to room temperature, and then the mixed dispersion is sheared. The shearing speed is 8000 rpm, the shearing time is 10 min, and the shearing ends, and it is a pigment red 112 dispersion.

[0021] The pigment red 112 dispersion of Example 1 was centrifuged at 5000 rpm for 30 minutes w...

Embodiment 2

[0023] (1) Take 10 parts of Pigment Red 112 by weight, 12 parts of dioctyl sodium succinate sulfonate, 4 parts of coco-based dimethyl tertiary amine, 5 parts of hydroxyethylene diphosphonic acid, and iso-myristate 3 parts of propyl ester, the above ingredients are mechanically mixed at a temperature of 40°C and stirred until uniform; (2) 2 parts of isotridecanol myristate are added to the mixed ingredients of step (1) by weight, 5 parts of polyvinylpyrrolidone, 8 parts of polyepoxysuccinic acid, 2 parts of sodium carboxymethyl starch, 200 parts of water, and then adjust the temperature to 50°C, and then stir until uniform; (3) Step (2) After uniformly stirring, the mixed components are cooled to room temperature, and then the mixed dispersion is sheared. The shearing speed is 4000rpm, the shearing time is 50min, and the shearing ends, and it is a pigment red 112 dispersion.

[0024] The pigment red 112 dispersion of Example 2 was centrifuged at 5000 rpm for 30 minutes without del...

Embodiment 3

[0026] (1) Take 12 parts of Pigment Red 112, 10 parts of dioctyl sodium succinate sulfonate, 9 parts of coco-based dimethyl tertiary amine, 6 parts of hydroxyethylene diphosphonic acid, and isomyristate by weight. 6 parts of propyl ester, the above ingredients are mechanically mixed at a temperature of 70°C and stirred until uniform; (2) 3 parts of isotridecanol myristate are added to the mixed ingredients of step (1) by weight, 7 parts of polyvinylpyrrolidone, 7 parts of polyepoxysuccinic acid, 4 parts of sodium carboxymethyl starch, 190 parts of water, and then adjust the temperature to 80°C, and then stir until it is uniform; (3) Step (2) After uniformly stirring, the mixed components are cooled to room temperature, and then the mixed dispersion is sheared. The shearing speed is 8000 rpm, the shearing time is 10 min, and the shearing ends, and it is a pigment red 112 dispersion.

[0027] The pigment red 112 dispersion of Example 3 was centrifuged at 6000 rpm for 30 minutes wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com