Coking fly ash-doped coal co-gasification method

A technology for coking dust removal and co-gasification, applied in the field of coal gasification, can solve the problems of affecting the health of workers, the proportion of coking dust removal into anthracite is low, and the coking dust removal can not be completely reused, etc. Melting temperature and viscosity temperature characteristics, solving the effect of narrow utilization range and reduction of raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] 1) Collect coal samples and coking dedusting ash (hereinafter referred to as dedusting ash), and grind them separately until the particle size is below 0.2 mm.

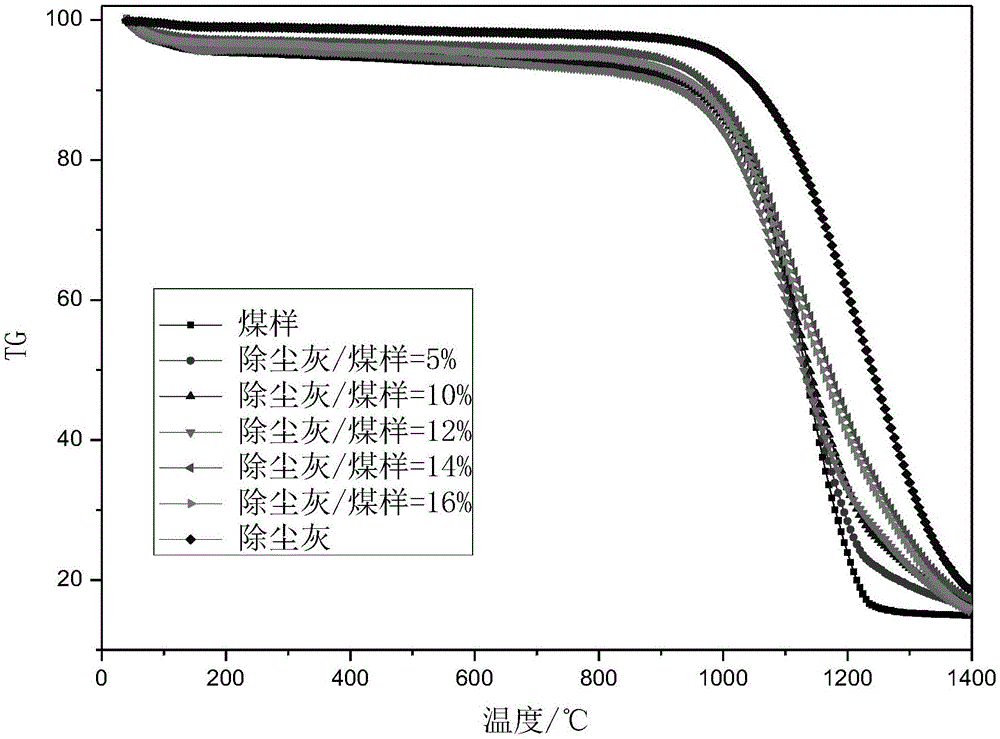

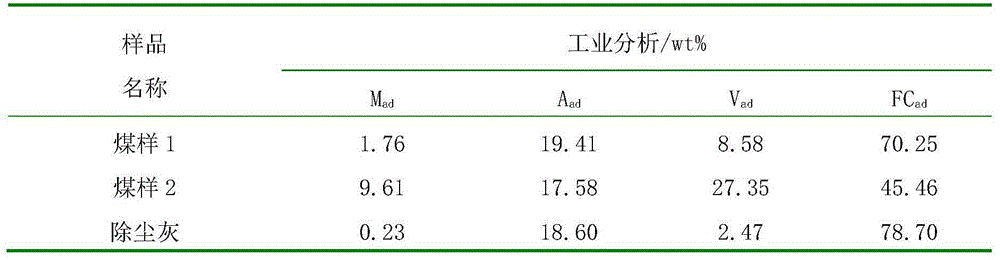

[0019] 2) The ground coal sample and the dedusted ash were analyzed for ash content, volatile matter, ash chemical composition, ash melting temperature and CO 2 Gasification reactivity measurement, see Table 1-4 for specific measurement results, wherein coal sample 1 is the sample coal sample, and coal sample 2 is the control coal sample;

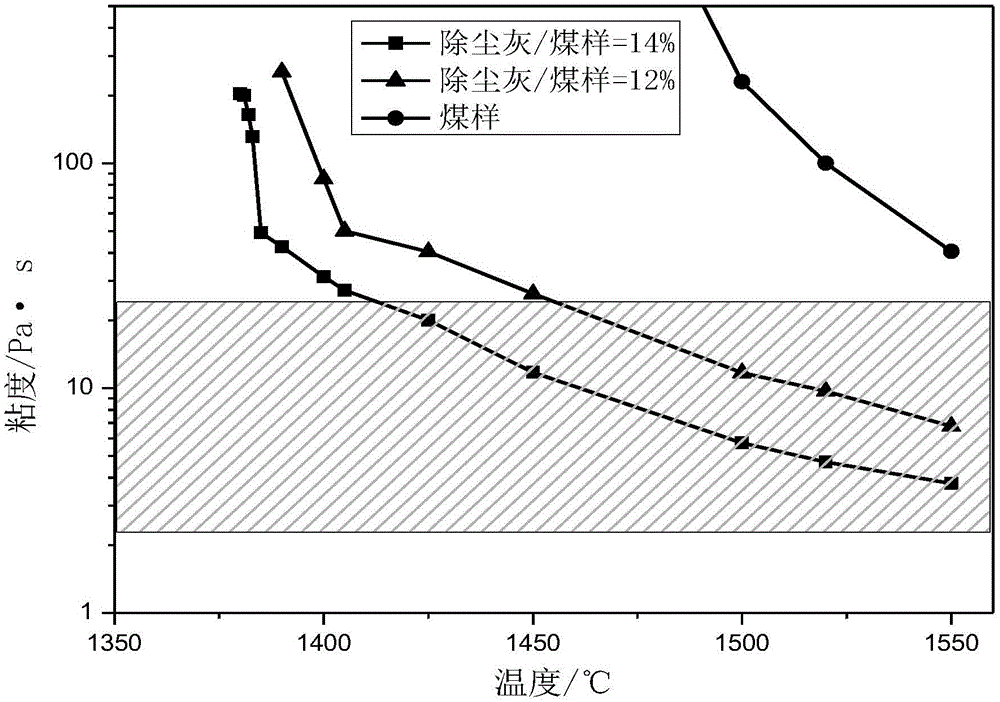

[0020] 3) According to the ash content, volatile matter, ash chemical composition, ash melting temperature and CO 2 For the gasification reactivity measurement, mix the dedusted ash and the coal sample at a mass ratio of (14-18):100 to obtain a mixed coal sample, so that the ash content of the mixed coal sample is 18%-20%, and the volatile content is 6%-8 %, the ratio of acidic oxides to basic oxides in the ash is 4.8-5.2, the ash flow temperature is 1340-1380°C, CO 2 Gasi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap