A continuous heat treatment furnace for motorcycle hub

A technology for heat treatment furnaces and motorcycles, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of affecting processing, low space and temperature utilization, wheel heating, etc., to achieve less deformation, improve space utilization, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

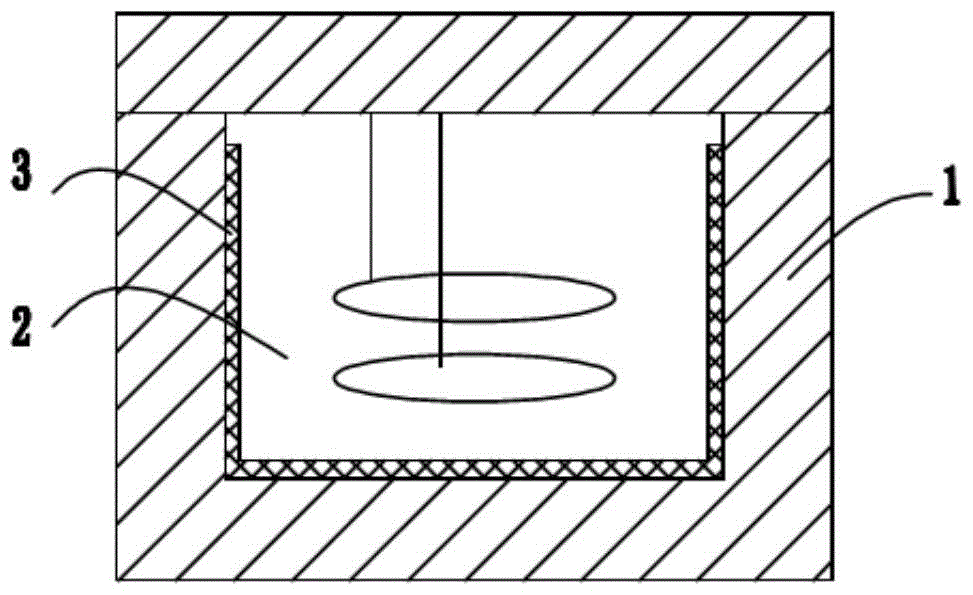

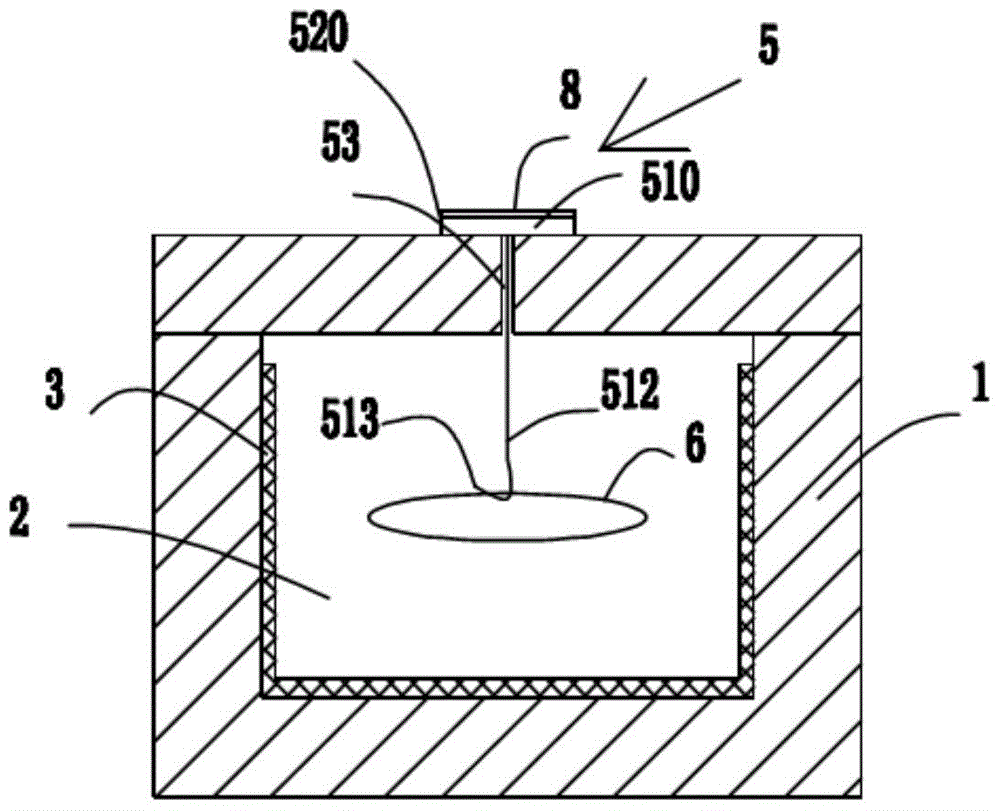

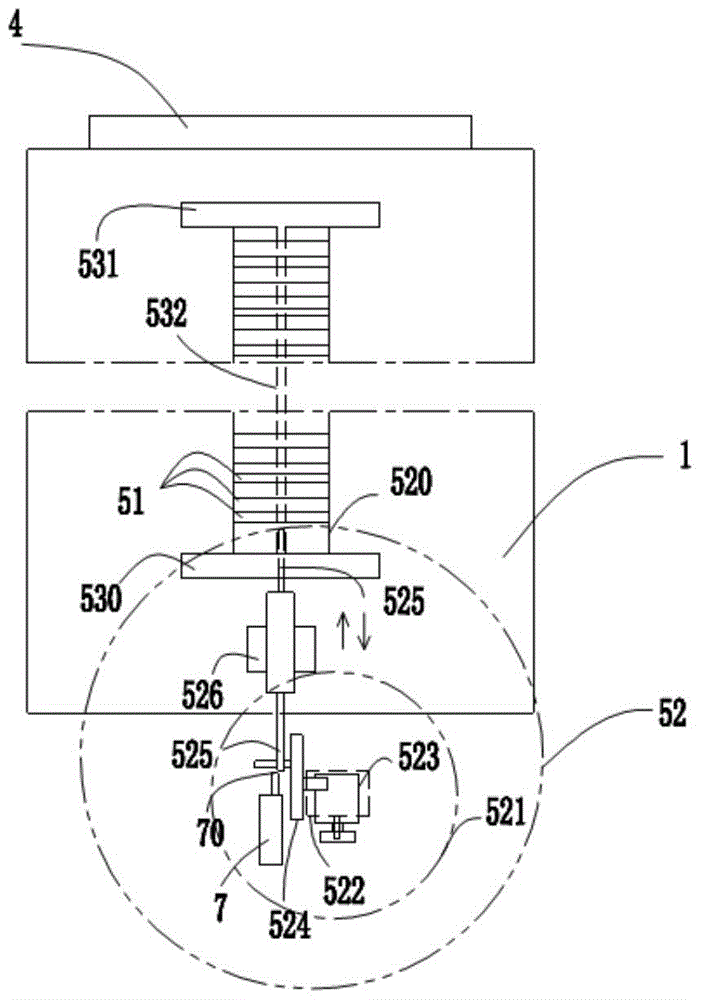

[0025] figure 2 It is a schematic sectional view of Embodiment 1 of the continuous motorcycle hub heat treatment furnace; image 3 It is a schematic top view of Embodiment 1; Figure 4 Schematic diagram of the structure of the hanger device. Such as figure 2 and image 3 As shown, the present invention provides a continuous heat treatment furnace for motorcycle wheels, a continuous heat treatment furnace for motorcycle wheels, which includes a furnace body 1, a heat treatment chamber 2, a heating body 3, and a furnace door 4, and the heating body 3 is located in the heat treatment chamber. It is heated in the chamber 2, and the furnace door 4 is arranged at one end of the furnace body 1, which can be opened or closed, and also includes a hanger moving system 5, which includes a plurality of hanger devices 51, The pushing mechanism 52 and the "I"-shaped opening 53 provided above the furnace body 1;

[0026] The hanger device 51, the hanger device 51 is in the shape of a ...

Embodiment 2

[0035] in, Figure 5 It is a schematic sectional view of embodiment two of the continuous motorcycle hub heat treatment furnace, as Figure 5 As shown, the heat treatment furnace of this embodiment includes two sets of hanger moving systems 5, and the systems are arranged side by side. This way can improve the space utilization rate in the furnace, so that the efficiency of heat treatment is higher.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com