a water pump

A technology of water pump and pump body, applied in the direction of pump, pump control, pump device, etc., can solve the problems of affecting the use of staff, the lift of the conveying liquid is not up to standard, affecting the normal operation of the pump, etc., and achieves the effect of instant response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

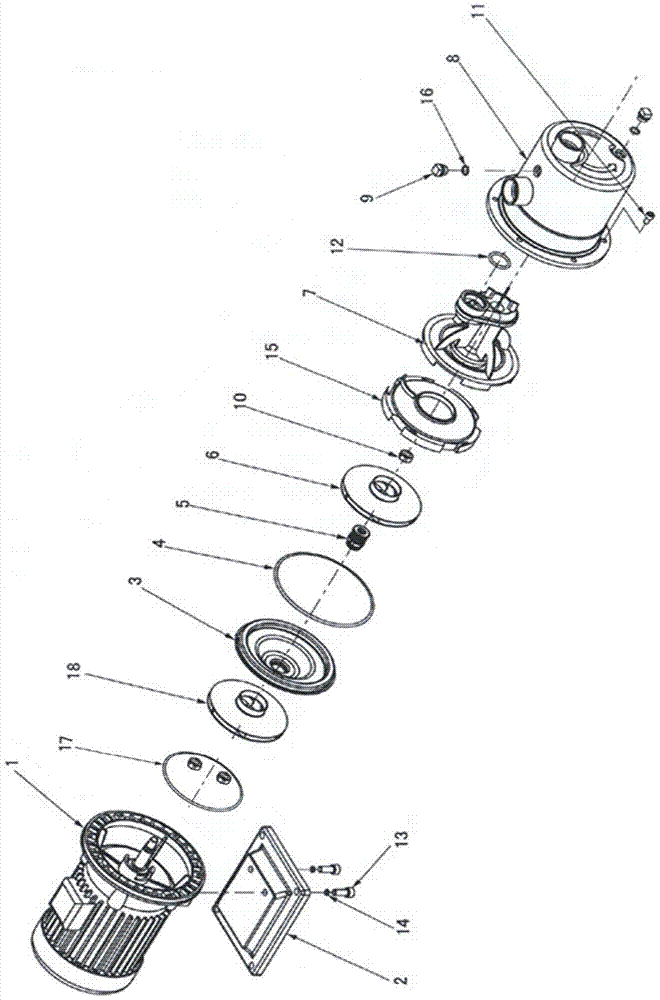

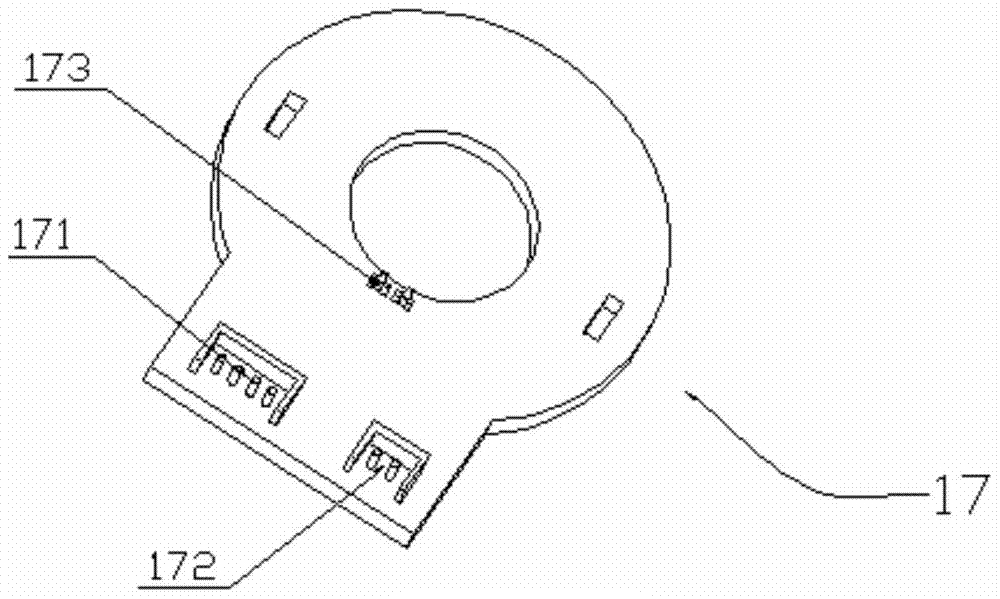

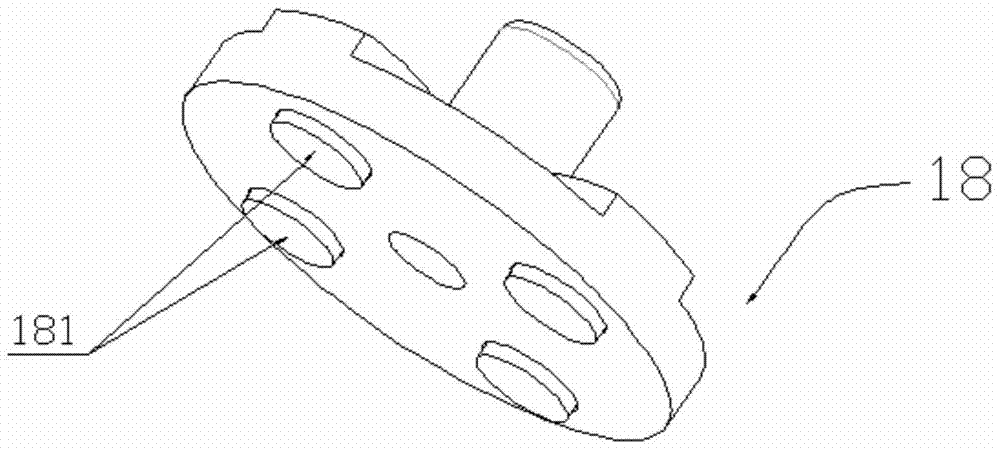

[0026] see figure 1 , figure 2 , image 3 and Figure 4 , a water pump, comprising a motor 1 and a pump body 8, and an impeller 6 sequentially connected between the motor 1 and the pump body 8, a guide vane 15 and a jet 7, the impeller 6 is sealed and fixedly connected with the output shaft of the motor 1, and the motor There is also a pump head liner 3 between 1 and the impeller 6, the pump head liner 3 is sealed and connected with the outer edge of the motor 1, and the edge joint is sealed with the first O-ring 4, and the output shaft of the motor 1 and the impeller 6 are mechanically connected. The sealing member 5 is sealed and connected, the output shaft of the motor 1 passes through the impeller 6, the guide vane 15, and its end is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com