Improved system and method for transformer and reactor noise source positioning and vibration detection

A technology for vibration detection and transformers, which is applied in the field of reactor noise source location and vibration detection, and improved transformers. It can solve problems such as low precision, inability to measure transformers, reactor vibration signals, and limited array placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below based on specific embodiments and in conjunction with the accompanying drawings.

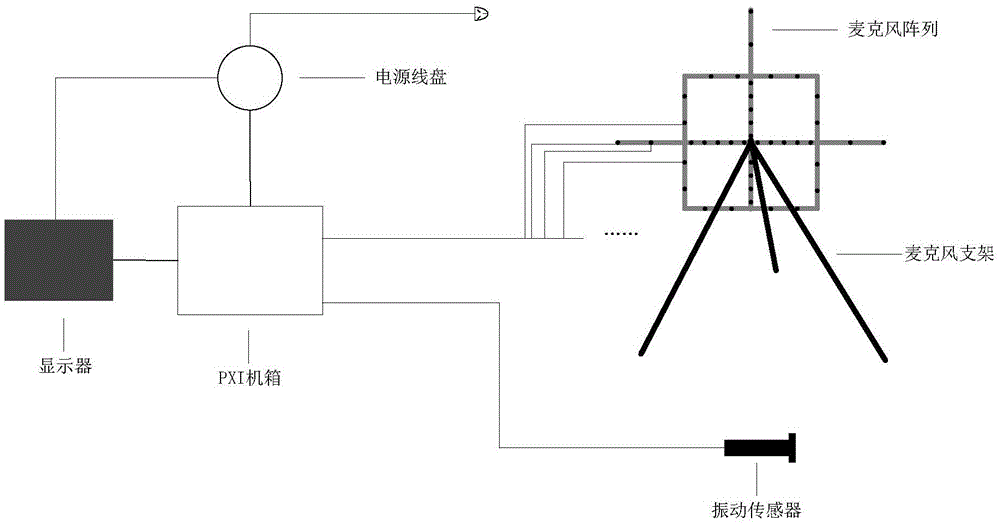

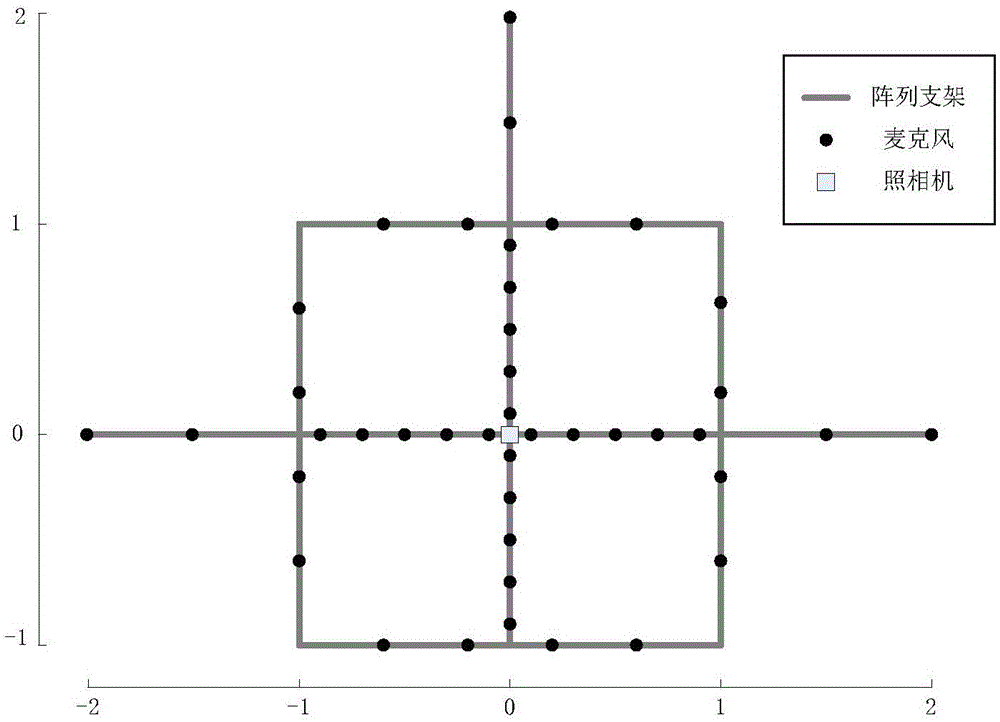

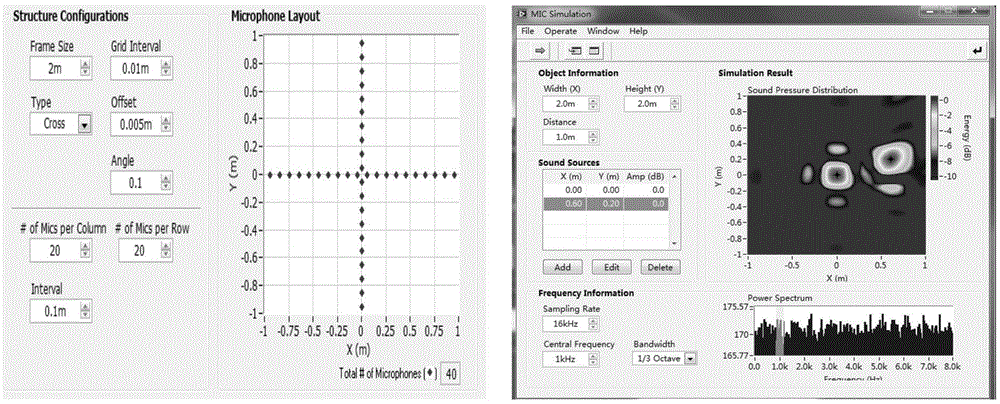

[0055] refer to Figure 1 ~ Figure 2 As shown, the improved transformer, reactor noise source location and vibration detection system of the present invention improves the layout of the microphones. On the basis of the original regular equidistant cross structure, it adopts a variable spacing design and adds horizontal and vertical microphones. The improved array aperture is expanded from the original 2m*2m to 4m*3m, which significantly improves the resolution of low-frequency sound. The distance between the microphones has been improved from the original 0.1m to 0.2, 0.4, 0.5m, etc. This irregularity has a significant effect on suppressing sidelobe ghosts and expanding the effective dynamic range of the array. The numerical simulation of the imaging results of the array is as follows: Figure 4 shown.

[0056] A specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com