Gas permeation testing method in low-permeability rock time-dependent deformation under action of thermal-gas-mecha-nical coupling

A thermal-mechanical coupling, gas permeation technology, applied in permeability/surface area analysis, measurement device, suspension and porous material analysis, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

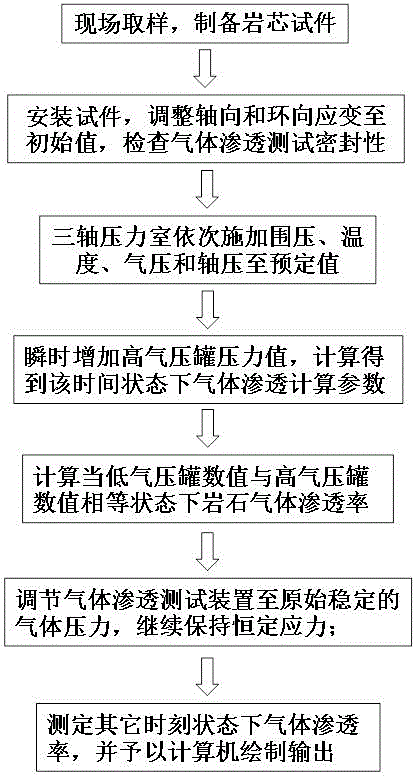

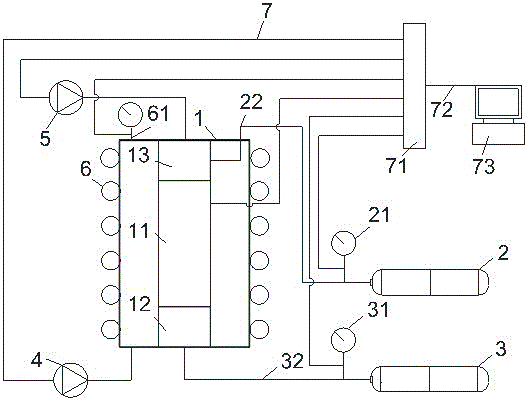

[0033] As shown in Figure 1, a test method for gas permeability in low-permeability rock aging deformation under gas-thermal-mechanical coupling includes the following steps in sequence:

[0034] Step S1: On-site survey and sampling of rock engineering, making core specimens; the core specimens are cylindrical, and the size meets the recommended standards of the International Society of Rock Mechanics. A cylindrical rock specimen with a diameter ratio of 2:1.

[0035] Step S2: Install the sample into the holder, adjust the axial and lateral strains to the initial values, and check the tightness of the gas permeation test;

[0036] Step S3: sequentially apply confining pressure, temperature, air pressure and axial pressure to a predetermined value on the triaxial pressure chamber; the specific method is: apply confining pressure to a predetermined value on the triaxial pressure chamber through a confining pressure loader; when the confining pressure is stable, Gradually apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com