Vortex line scanning thermal imaging detection system and method

A detection system and detection method technology, which is applied in the fields of equipment non-destructive testing, structural health monitoring and product quality control, can solve the problems of low detection accuracy, poor imaging effect, low detection efficiency, etc., and achieve high detection efficiency and low detection cost , good imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

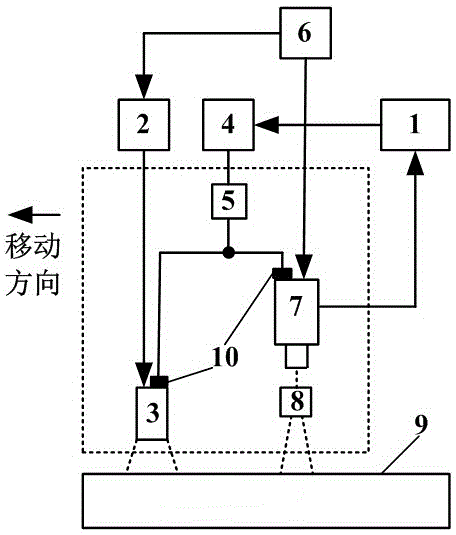

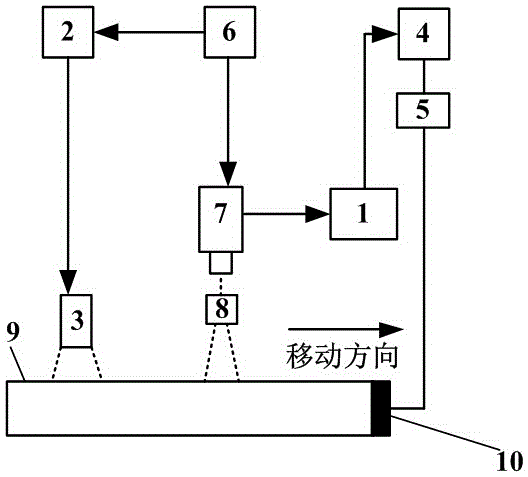

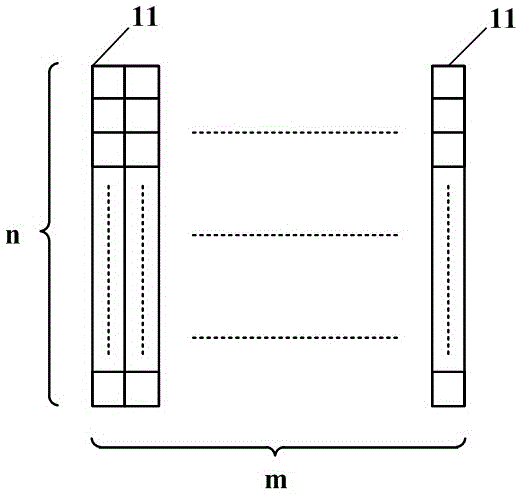

[0040] Such as figure 1 As shown, an embodiment of the detection system of the present invention includes a trigger 6 with two output ends, one output end of the trigger 6 is connected to the linear coil 3 through the eddy current heating module 2, and the other output of the trigger 6 End is connected with one-dimensional thermal imager 7, and described one-dimensional thermal imager 7 is configured in order to adjust the lens 8 of field of view size, and the output end of described one-dimensional thermal imager 7 is connected with computer 1, also includes computer 1 A scan control module 4 connected to the output end of the scan control module 4, the output end of the scan control module 4 is connected to the motion device 5, and the motion device 5 has a clamping device 10, and the clamping device 10 is respectively connected to the linear coil 3 and a The three-dimensional thermal imager 7 is fixedly connected, and the side of the linear coil 3 that performs linear heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com