Converter valve assembly and its igbt sub-module for flexible direct current transmission

A technology of flexible direct current transmission and converter valves, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as complex installation structures, achieve the effects of improving reliability, improving heat dissipation environment, and simplifying press-fitting and fixing structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

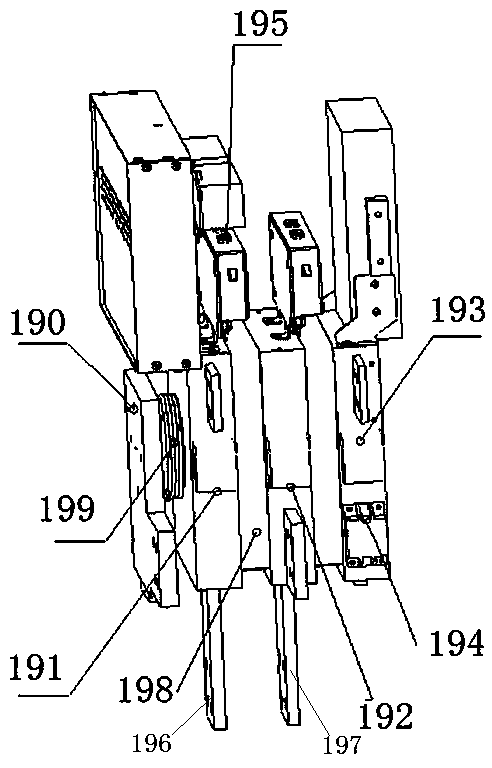

[0031] Such as figure 1 Shown, a kind of embodiment of IGBT submodule, the submodule in this embodiment includes 2 IGBT198, 3 radiators and 1 thyristor 199, and 3 radiators are right radiator 191, middle radiator 192 and The radiator 193 on the left side, 2 IGBTs and 3 radiators are arranged at intervals along the left and right directions, one thyristor 199 is arranged outside the radiator 191 on the right side, and the veneers corresponding to the 2 IGBTs are fixedly mounted on the radiator On the corresponding side of the radiator, the thyristor 199 is fixedly installed on the outer surface of the right radiator 191 with a corresponding veneer, and the right side of the thyristor 199 is provided with a conductive aluminum bar for cooperating with the right radiator 191 to clamp the thyristor 199. 190. Wherein, a resistor 194 is fixedly mounted on the left side radiator 193 . Moreover, sub-module control circuits 195 are also fixedly installed on the three radiators.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com