Substrates for power modules, substrates for power modules with built-in heat sinks, and power modules

A power module and heat sink technology, which is applied in the direction of electric solid state devices, circuit heating devices, semiconductor devices, etc., can solve the problems of inability to promote heat dissipation, inability to form cooling capacity, insufficient heat sink strength, etc., and achieve excellent power cycle characteristics, Effects of suppressing cracks and effectively dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] A comparative experiment performed to confirm the effectiveness of the present invention will be described.

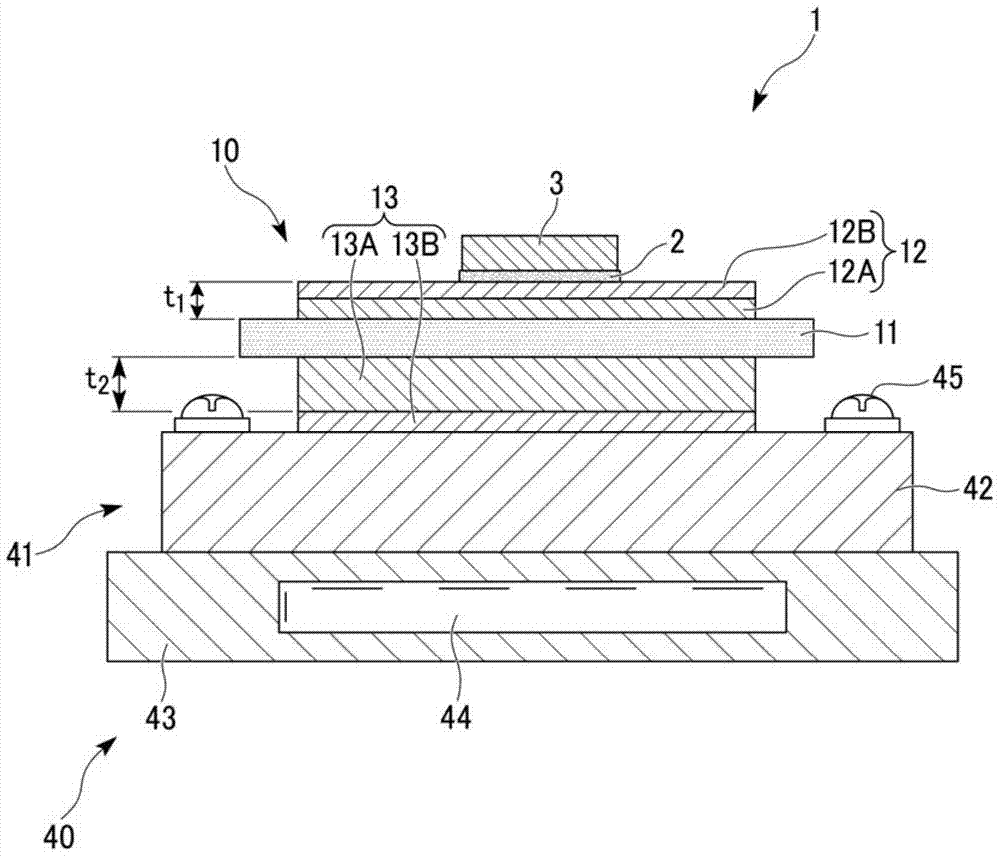

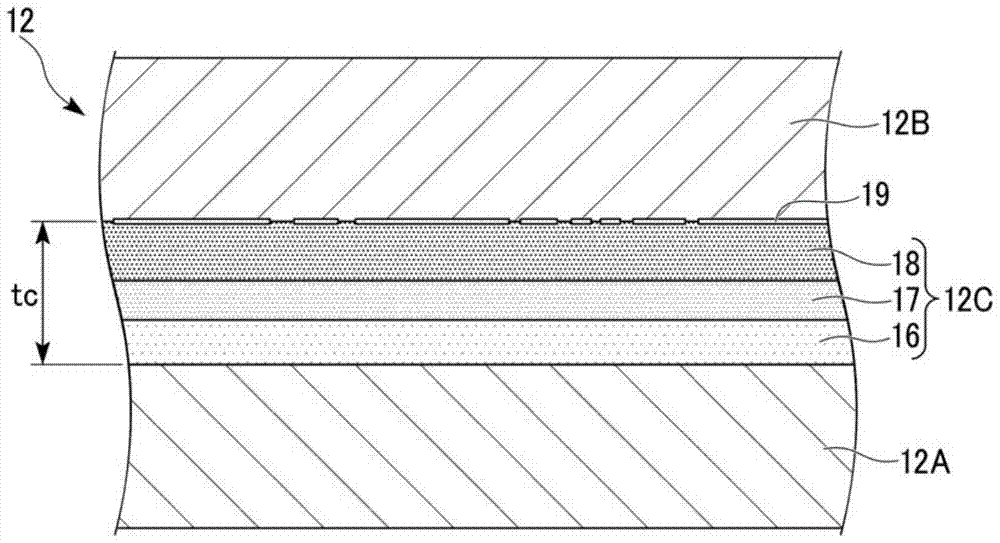

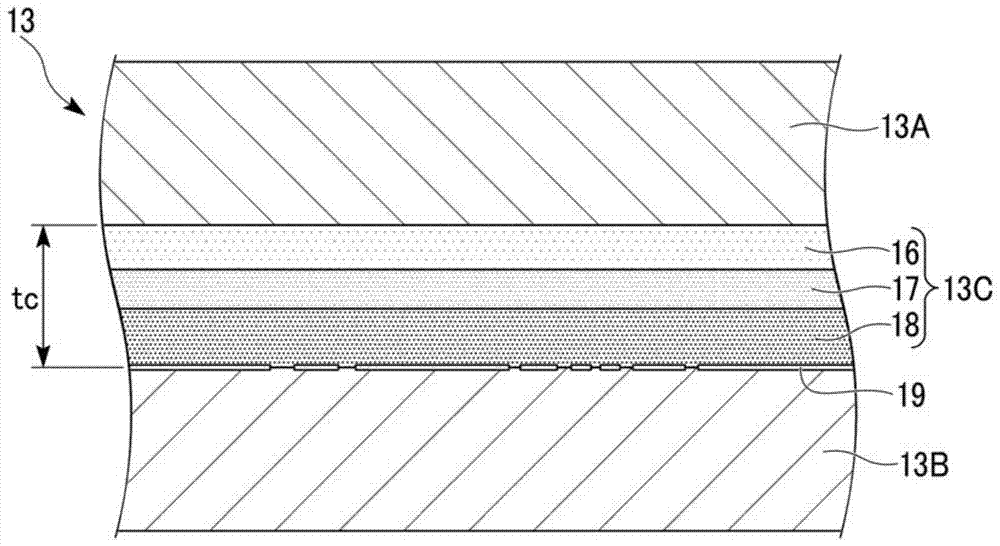

[0149] As shown in Table 1, bond the insulating substrate, the aluminum plate serving as the first aluminum layer of the circuit layer, the copper plate serving as the first copper layer, the aluminum plate serving as the second aluminum layer of the metal layer, and the copper plate serving as the second copper layer. To produce substrates for power modules.

[0150] The size of the circuit layer is 37mm×37mm, the size of the insulating substrate is 40mm×40mm, and the size of the metal layer is 37mm×37mm.

[0151] "TLP" shown in Table 2, by adding Cu to 1.0mg / cm 2 fixed on the surface of the insulating substrate, and on the stacking side with 5kgf / cm 2 In the pressurized state, at 10 -3 In a vacuum of Pa, the aluminum plate and the insulating substrate were bonded by heating at a temperature of 600° C. for 30 minutes.

[0152] "Al-Si brazing" shown in Table...

Embodiment 2

[0181] Next, as in the above-mentioned second embodiment and Figure 6 As shown in , the metal layer of the power module substrate and the heat sink were joined via the second solder layer, and the joining rate of the second solder layer was evaluated.

[0182] As shown in Table 3, an insulating substrate, an aluminum plate as the first aluminum layer of the circuit layer, a copper plate as the first copper layer, an aluminum plate as the second aluminum layer as the metal layer, and a copper plate as the second copper layer were fabricated to produce a power Module substrate.

[0183] The size of the circuit layer is 37mm×37mm, the size of the insulating substrate is 40mm×40mm, and the size of the metal layer is 37mm×37mm.

[0184] In addition, "TLP" and "Al-Si brazing" shown in Table 4 were made into the same joining method as Example 1 and Table 2 mentioned above.

[0185] In addition, a heat sink is bonded to the other side of the metal layer of the power module substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com