High power barreled

A high-power, chip technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of high chip junction temperature, discoloration of light-transmitting medium, accelerated light decay, etc., and achieve low chip junction temperature, high luminous efficiency, Good general effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

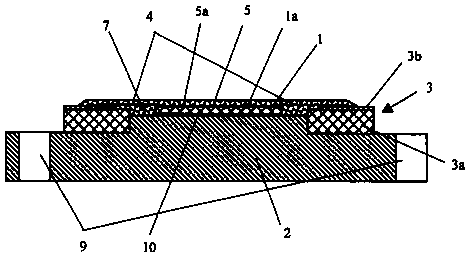

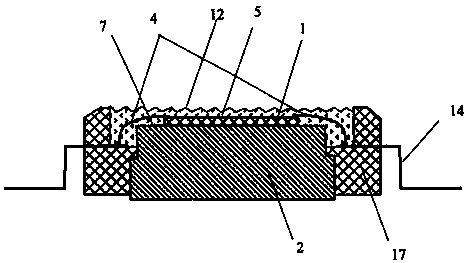

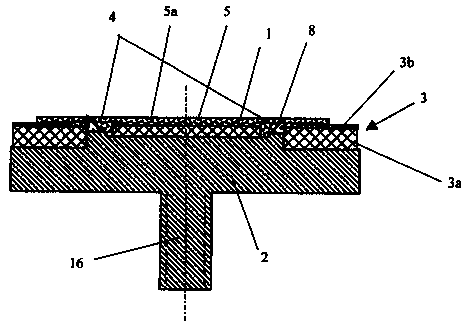

[0023] The indications in the attached drawings are:

[0024] 1-LED chip 2-Metal base 3-Electrical connection device

[0025] 3a-insulating layer 3b-conducting layer 4-lead

[0026] 5 - Light-transmitting protective layer or layer of luminescent material 5a - Luminescent material or light scattering material

[0027] 6-luminescent material layer 7-light reflection layer 8-light reflection bowl

[0028] 9-Screw hole 10-High thermal conductivity material 11-Flip chip

[0029] 12-Uneven surface 13-Light-emitting material layer 14-Metal lead wire

[0030] 15-Circuit board and metal lead wire 16-Screw 17-Insulation frame

[0031] 18-Conductive material 19-Fixing glue

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings: figure 1 Shown is a schematic structural diagram of an embodiment of the high-power light emitting diode of the present invention. It includes at least one light-emitting diode chip 1, at least one met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com