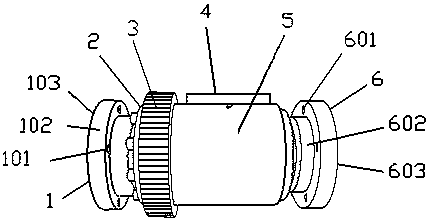

Vehicle automatic anti-skid differential mechanical device

An automatic anti-skid, mechanical device technology, applied in the direction of transmission parts, control devices, vehicle parts, etc., can solve the problems of slow heat dissipation, shortened equipment service life, parts aging, etc., to improve service life and work stability, reduce effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

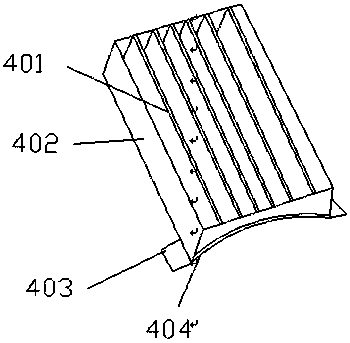

[0017] Heat sink thickness-mm 1 2 3 Heat dissipation efficiency-J / s 5000 4500 3500

[0018] It can be seen from the above table that when the thickness of the heat sink is 1mm, the heat dissipation efficiency is the highest, which is the optimal solution. By installing a heat sink, the heat generated during the operation of the device can be effectively dissipated, and the temperature of the device can be effectively reduced. The service life and working stability of the equipment are improved.

[0019] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. For those skilled in the art, it is obvious that the present invention is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com