Movable anti-explosion vacuum dust collection device and anti-explosion control method thereof

A vacuum cleaning and control method technology, applied in the direction of vacuum cleaners, installation of electrical equipment, cleaning equipment, etc., can solve problems such as secondary explosions, unfavorable production safety, threats to the surrounding environment, etc., to eliminate potential safety hazards, avoid combustion explosions, The effect of eliminating the hazard of secondary explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

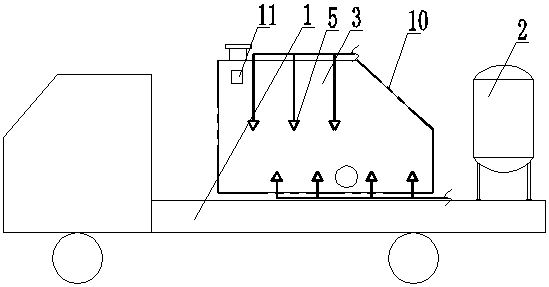

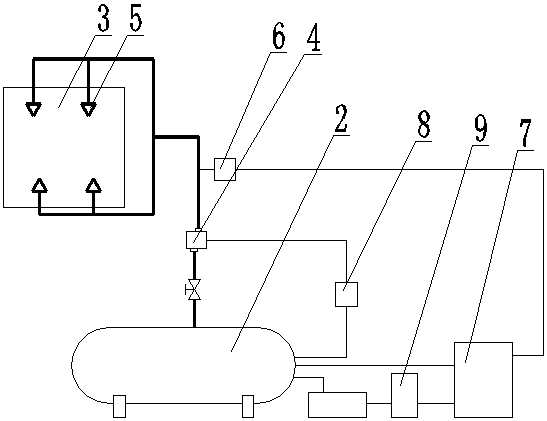

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] like figure 1 and figure 2 The mobile explosion-proof vacuum cleaner shown, the vacuum cleaner is located on the mobile platform 1, CO 2 The inerting protection system is connected to the mobile platform 1, CO 2 The inerting protection system consists of a CO connected to the mobile platform 1 2 Storage tank 2, CO 2 injection system, control system, and the CO 2 The refrigerating unit connected to the storage tank 2, the storage device controller 9; CO 2 Injection system includes through piping with CO 2 The main control valve 4 connected to the storage tank 2, several nozzles located inside the silo 3 of the vacuum cleaner and the inerting dust-proof nozzle 5 connected to the main control valve 4 through pipelines, the valve position signal feedback device of the main control valve 4 6; the control system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com