Multi-angle drilling device for vehicle pipe fitting

A drilling device, multi-angle technology, applied in the direction of driving device, boring/drilling, drilling/drilling equipment, etc., can solve the problems of slow speed, unstable quality, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

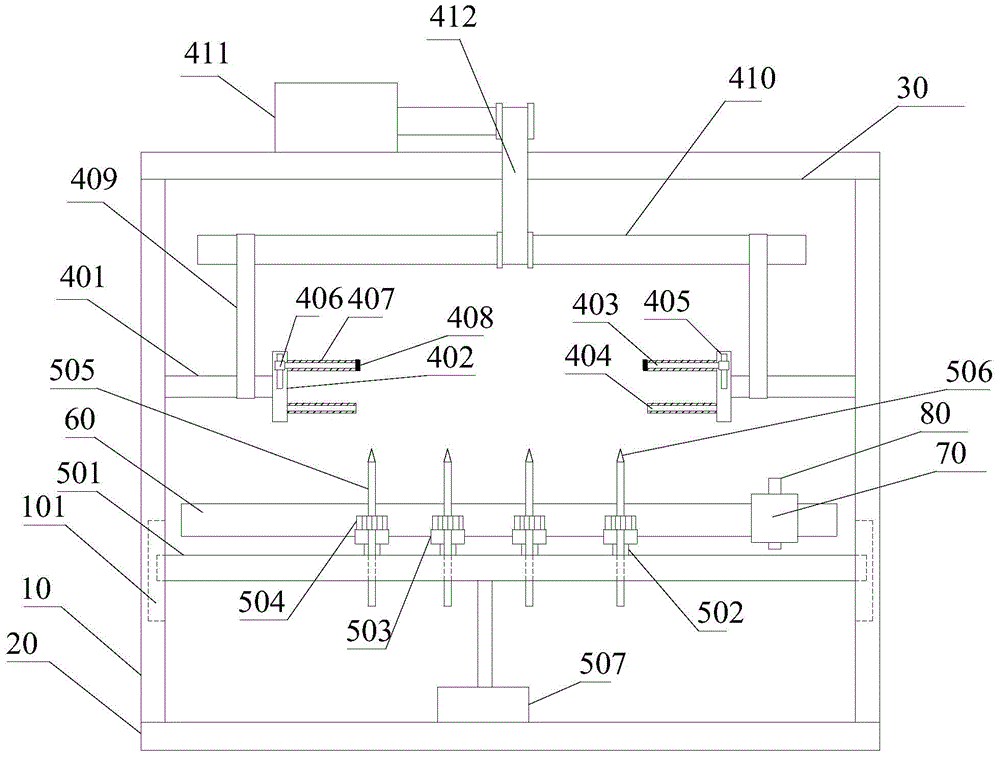

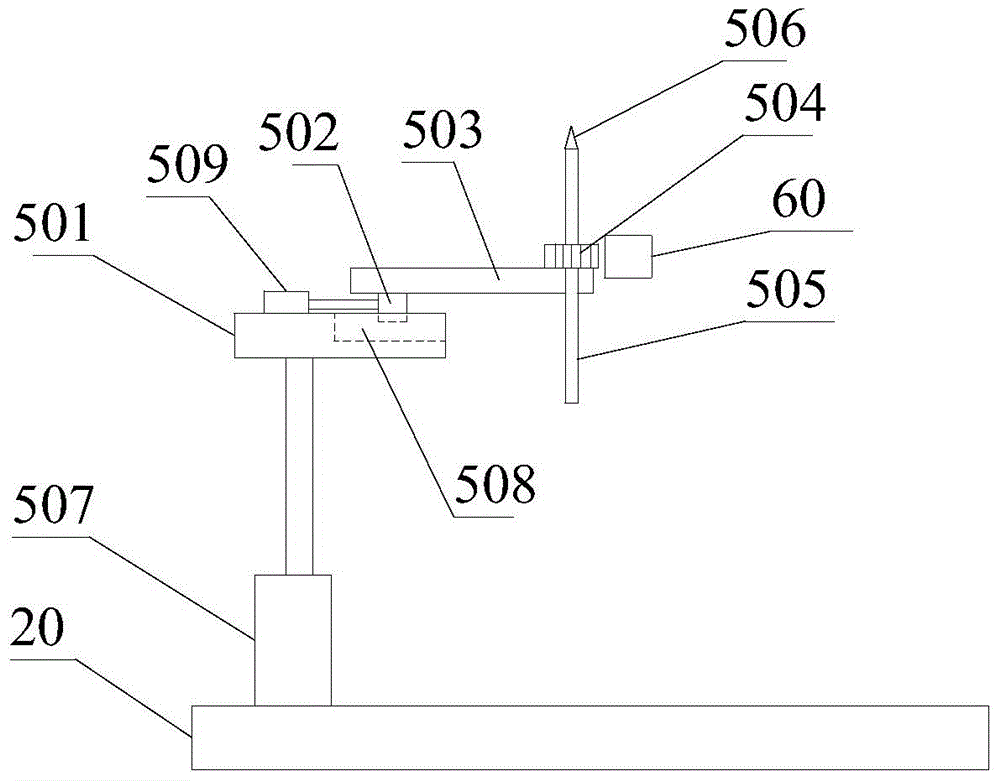

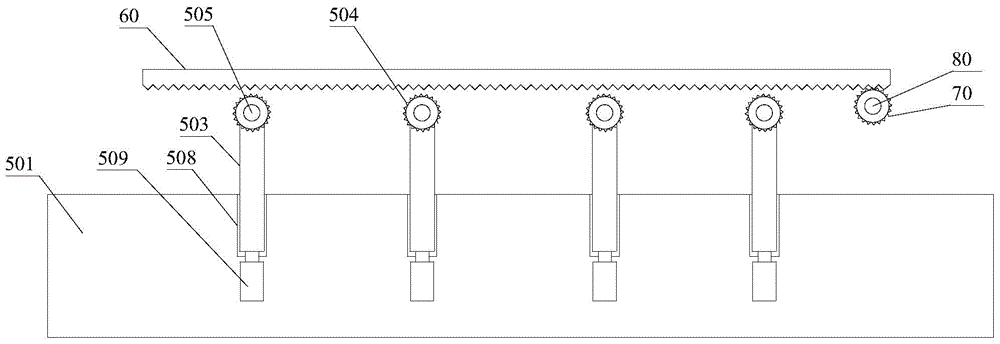

[0021] The present invention proposes a multi-angle drilling device for automobile pipe fittings, including a frame 10, a first bracket 30, a second bracket 20, a clamping mechanism, a drilling mechanism, a controller, a rack 60, a first gear 70, and a drive shaft 80.

[0022] Such as figure 1 As shown, the first bracket 30 and the second bracket 20 are installed on the frame 10 respectively, and a working area is formed between the first bracket 30 and the second bracket 20, and the clamping mechanism and the drilling mechanism are located in the working area.

[0023] Such as figure 1 As shown, the clamping mechanism includes a third driving device 411 installed on the first bracket 30, a transmission mechanism, and two symmetrically arranged clamping devices; each clamping device includes a first rotating shaft 401, and is installed on the first rotating shaft. The pole 402 on the pole 401 and the first support plate 403 and the second support plate 404 that are symmetric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com