A sealing ring processing method and a sealing ring processed by the method

A processing method and sealing ring technology, which are applied in engine sealing, metal processing equipment, machine tools suitable for grinding workpiece planes, etc., can solve problems such as large surface roughness, difficult processing, and low forming accuracy, and achieve processing The effect of high precision, strong convergence characteristics, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

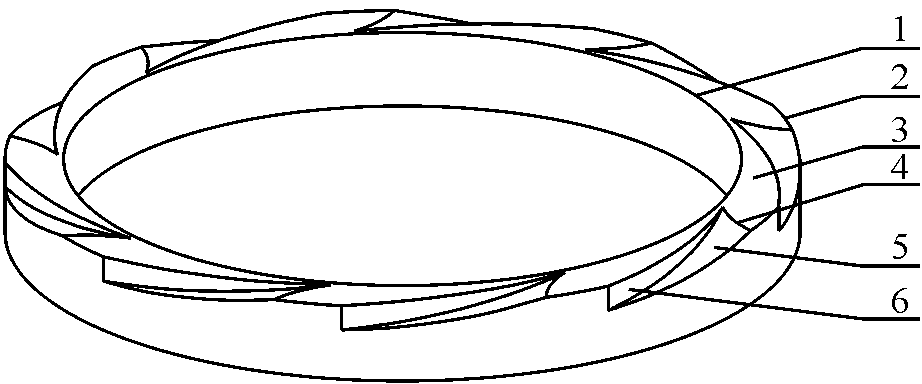

[0089] Example 1: Please refer to figure 1 , figure 2 and image 3 .

[0090] A method for processing a sealing ring, comprising the steps of grinding the sealing end surface of the sealing ring and the step of grinding the shallow groove on the sealing end surface, firstly using a cup-shaped grinding wheel to grind the sealing end surface of the sealing ring, and then using the cup-shaped grinding wheel to grind the shallow groove groove. In the step of grinding the sealing end face, the cup-shaped grinding wheel rotates around the axis of the grinding wheel, the sealing ring rotates around the axis of the sealing ring, and the cup-shaped grinding wheel makes a cutting movement relative to the workpiece surface to remove the machining allowance of the sealing end face. For the end face, it is divided into two stages: coarse grinding and fine grinding. In the step of grinding shallow grooves, the radius of the cup-shaped grinding wheel is 175 mm, the width of the end face...

Embodiment 2

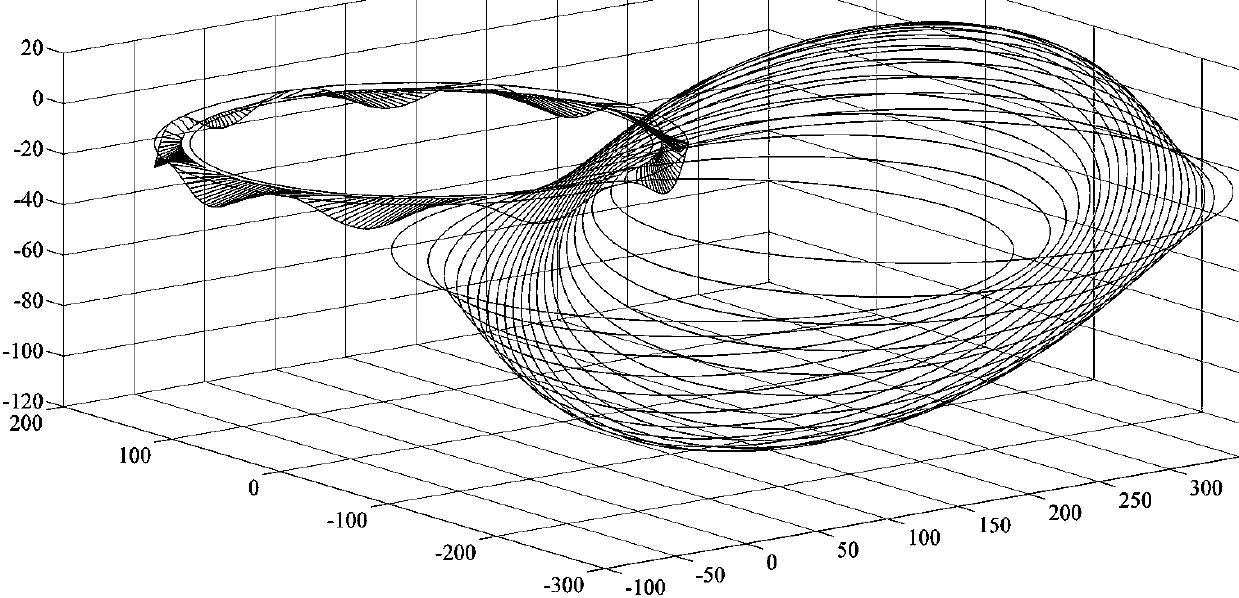

[0095] Example 2: Please refer to Figure 4 , Figure 5 , Figure 6 and Figure 7 .

[0096] A method for processing a sealing ring, comprising the steps of grinding the sealing end surface of the sealing ring and the step of grinding the shallow groove on the sealing end surface, firstly using a cup-shaped grinding wheel to grind the sealing end surface of the sealing ring, and then using the cup-shaped grinding wheel to grind the shallow groove groove. In the step of grinding the sealing end face, the cup-shaped grinding wheel rotates around the axis of the grinding wheel, the sealing ring rotates around the axis of the sealing ring, and the cup-shaped grinding wheel makes a cutting motion relative to the surface of the workpiece to remove the machining allowance of the sealing end face. In the step of grinding the shallow groove, the radius of the cup grinding wheel is 175mm, and the inclination angle between the cup grinding wheel and the sealing end face is 0.00081 ra...

Embodiment 3

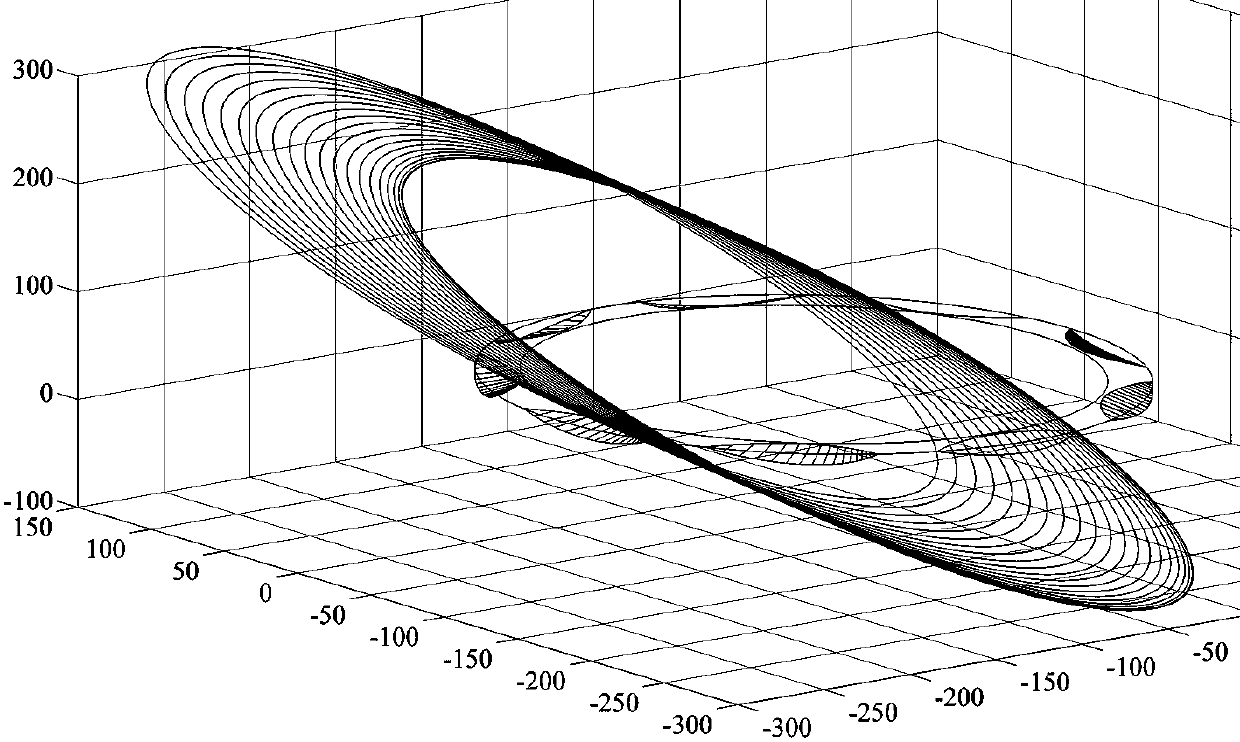

[0101] Example 3: Please refer to Figure 8 , Figure 9 and Figure 10 .

[0102] A method for processing a sealing ring, comprising the steps of grinding the sealing end surface of the sealing ring and the step of grinding the shallow groove on the sealing end surface, firstly using a cup-shaped grinding wheel to grind the sealing end surface of the sealing ring, and then using the cup-shaped grinding wheel to grind the shallow groove groove. In the step of grinding the sealing end face, the cup-shaped grinding wheel rotates around the axis of the grinding wheel, the sealing ring rotates around the axis of the sealing ring, and the cup-shaped grinding wheel makes a cutting motion relative to the surface of the workpiece to remove the machining allowance of the sealing end face. In the step of grinding the shallow groove, the radius of the cup wheel is 175 mm, and the distance from the center of the end face of the cup wheel to the axis of the seal ring is 263 mm, except fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com