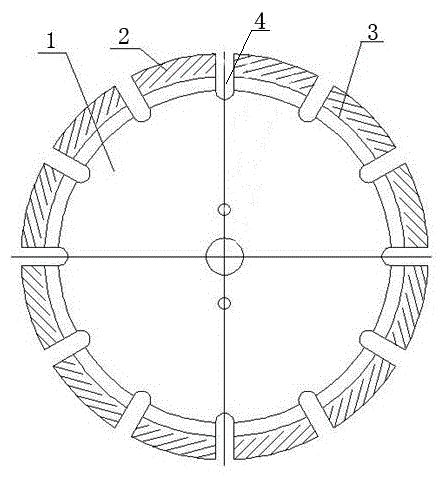

Three-dimensional distribution diamond cutter and preparing technology thereof

A diamond tool, three-dimensional distribution technology, applied in the direction of manufacturing tools, stone processing tools, stone processing equipment, etc., can solve the problems of increased cost, complexity, cumbersome welding process and steps, etc., and achieve the effect of prolonged service life and good sharpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The manufacturing process of the above-mentioned three-dimensional distribution diamond cutter comprises the following steps:

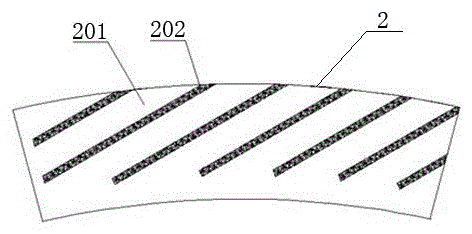

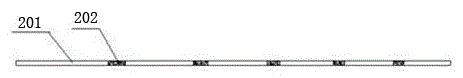

[0024] 1) Take the existing steel saw blade as the saw blade body 201, and process several parallel slits on its surface as the diamond slits 202. The distance between the diamond slits 202 is set according to the needs, and the width is 100% of the particle size of the diamond powder. 2-3 times, and the direction of the diamond kerf 202 is at an angle of 30° to the transverse centerline of the rectangular plane formed after the saw blade body 201 is deployed;

[0025] 2) Take commercially available BNi7 flux paste for brazing diamond, and mix it with 40-100 mesh diamond powder and external reinforcement particles to make composite solder paste, and then fill the composite solder paste into the diamond kerf 202 ,spare;

[0026] In the composite solder paste, the weights of diamond powder and additional reinforcing particles are respectively 10...

Embodiment 2

[0031] The manufacturing process of the above-mentioned three-dimensional distribution diamond cutter comprises the following steps:

[0032] 1) Take the existing steel saw blade as the saw blade body 201, and process several parallel slits on its surface as the diamond slits 202. The distance between the diamond slits 202 is set according to the needs, and the width is 100% of the particle size of the diamond powder. 2-3 times, and the direction of the diamond kerf 202 is at an angle of 60° to the transverse centerline of the rectangular plane formed after the saw blade body 201 is deployed;

[0033] 2) Take the commercially available BNi2 flux paste for brazing diamond, and mix it with 40-100 mesh diamond powder and additional reinforcement particles to make a composite solder paste, and then fill the composite solder paste into the diamond kerf 202 ,spare;

[0034] In the composite solder paste, the weights of diamond powder and additional reinforcement particles are 30% a...

Embodiment 3

[0039] The manufacturing process of the above-mentioned three-dimensional distribution diamond cutter comprises the following steps:

[0040] 1) Take the existing steel saw blade as the saw blade body 201, and process several parallel slits on its surface as the diamond slits 202. The distance between the diamond slits 202 is set according to the needs, and the width is 100% of the particle size of the diamond powder. 2-3 times, and the direction of the diamond kerf 202 is at an angle of 45° to the transverse centerline of the rectangular plane formed after the saw blade body 201 is deployed;

[0041] 2) Take commercially available CuSnTi brazing flux paste for diamond brazing, mix it with 40-100 mesh diamond powder and additional reinforcement particles to make composite brazing paste, and then fill the composite brazing paste into the diamond kerf 202 ,spare;

[0042] In the composite solder paste, the weights of the diamond powder and the added reinforcing particles are re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com