A kind of multi-functional layer nitride low radiation energy-saving glass

An energy-saving glass and low-radiation technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve poor weather resistance and corrosion resistance, reduce the life of glass products, increase production costs and film systems Complexity and other issues, to achieve good corrosion resistance, reduce the difficulty of production technology, and soft colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

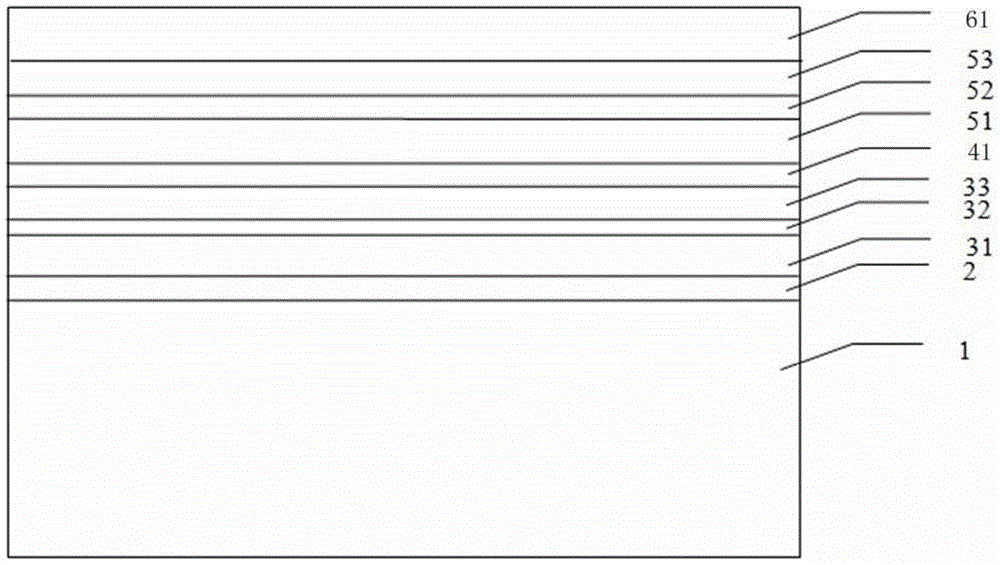

[0021] The invention provides a multi-functional layer nitride low-radiation energy-saving glass, the multi-functional layer nitride low-radiation energy-saving glass includes a coated glass substrate 1, and the coated glass substrate is sequentially provided with Na+ ion barriers from the inside to the outside. depositing a barrier layer, a first functional layer, a second functional layer, a third functional layer and a protective layer;

[0022] The deposition barrier layer is the first silicon nitride film layer 2; the first functional layer is composed of three continuous film layers, and the three continuous film layers include the first aluminum nitride film layer 31, the first nitride film layer Titanium film layer or metal titanium film layer 32, second aluminum nitride film layer 33; second functional layer is zirconium nitride film layer 41; third functional layer is third aluminum nitride film layer 51, second titanium nitride film layer The film layer 52 and the f...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that the present invention provides a low-emissivity energy-saving glass with a multifunctional nitride layer, and the thickness of the silicon nitride film layer is 15 nm.

[0035] The thickness of the first aluminum nitride film layer 31 is 30nm; the thickness of the first titanium nitride film layer or metal titanium film layer 32 is 9nm, which is a low emissivity layer; the thickness of the second aluminum nitride film layer 33 is 20nm.

[0036] The thickness of the zirconium nitride film layer 41 is 18nm.

[0037] The thickness of the third aluminum nitride film layer 51 is 28nm; the thickness of the second titanium nitride film layer 52 is 17nm; the thickness of the fourth aluminum nitride film layer 53 is 20nm; the second silicon nitride film layer 61 has a thickness of 30 nm.

Embodiment 3

[0039] The difference between embodiment 3 and embodiment 1 is that the thickness of the first silicon nitride film layer 2 in the present invention is 20 nm. The thickness of the first aluminum nitride film layer 31 is 35nm; the thickness of the first titanium nitride film layer or metal titanium film layer 32 is 15nm; the thickness of the second aluminum nitride film layer 33 is 28nm. The thickness of the zirconium nitride film layer 41 is 20nm. The thickness of the third aluminum nitride film layer 51 is 38nm; the thickness of the second titanium nitride film layer 52 is 25nm; the thickness of the fourth aluminum nitride film layer 53 is 25nm; the second silicon nitride film layer 61 has a thickness of 42 nm.

[0040]Although the coated glass substrate 1, the first silicon nitride film layer 2, the first aluminum nitride film layer 31, the second titanium nitride film layer or metal titanium film layer 32, and the second aluminum nitride film layer are used more frequently...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com