Polymeric material for 3D printing and preparation method of polymeric material

A polymer material and 3D printing technology, applied in the field of polymer materials, can solve the problems of low elastic modulus and large molding shrinkage rate, and achieve the effect of high tensile modulus, high tensile strength and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

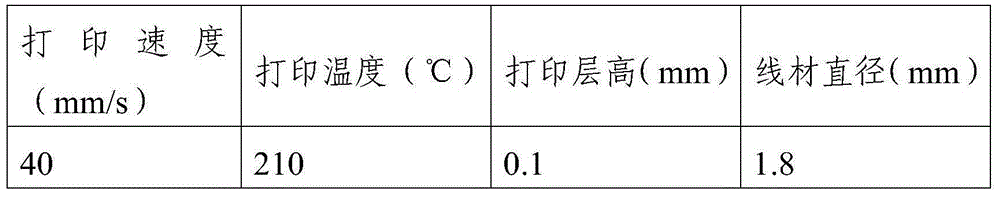

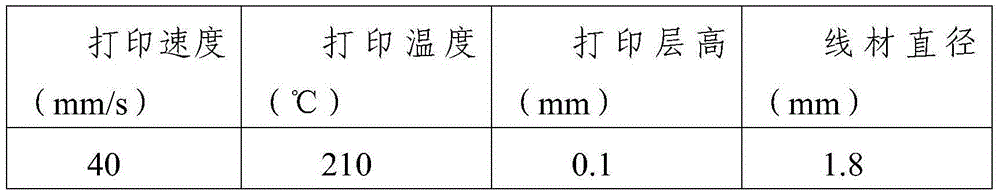

Examples

Embodiment 1

[0032] This embodiment relates to a polymer material for 3D printing, and its raw material composition is 60 parts by weight of polybutylene succinate, 40 parts by weight of polylactic acid and 1 part by weight of iron yellow.

Embodiment 2

[0034] This embodiment relates to a polymer material for 3D printing, and its raw material composition is 20 parts by weight of polybutylene succinate, 80 parts by weight of polylactic acid and 1 part by weight of iron yellow.

Embodiment 3

[0036] This embodiment relates to a polymer material for 3D printing, and its raw material composition is 100 parts by weight of polybutylene succinate, 5 parts by weight of attapulgite and 1 part by weight of phthalocyanine blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com