Method for replacing ascending pipe base of coke oven

A replacement method and riser technology, applied in coke ovens, heating of coke ovens, petroleum industry, etc., can solve the problems of prolonging the use time of risers, long construction time, and high construction costs, so as to reduce the cost of repair projects and repair projects The effect of good quality and large safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A 2×55-hole 6-meter coke oven in a coking plant of a steel factory was completed and put into operation in 2008. In 2013, 24 riser bases were severely damaged, and partial repairs could no longer meet production needs. The top of the riser is 20 meters above the ground, and a 100-ton crane is needed to replace the bottom of the riser, which is costly and poses a great safety hazard.

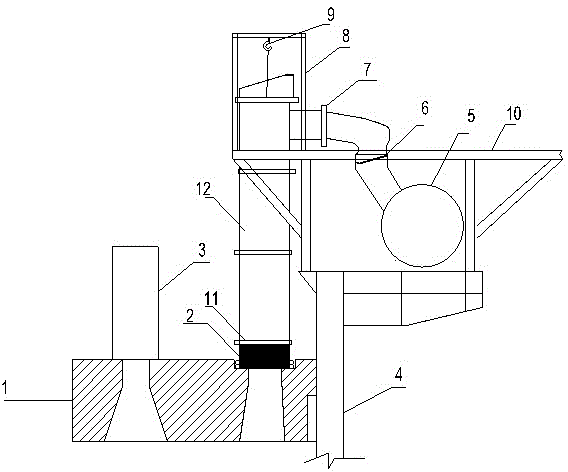

[0032] see now figure 1 , figure 1 It is a schematic diagram of the construction method for replacing the coke oven riser base of the embodiment of the present invention.

[0033] The coke oven riser base replacement method of the present invention is characterized in that it comprises the following steps:

[0034] 1. Install temporary chimney 3: Install a temporary steel pipe with a diameter of 710mm (slightly larger than the diameter of the coal charging hole) and a height of 1750mm on the top of the coke oven replacement furnace next to the coal charging hole of the ascending pipe. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com