Anti-creep rare earth magnesium alloy and preparation method thereof

A rare-earth magnesium and anti-creep technology, which is applied in the field of preparation of creep-resistant rare-earth magnesium alloys and creep-resistant rare-earth magnesium alloys, and can solve problems such as not being able to meet the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

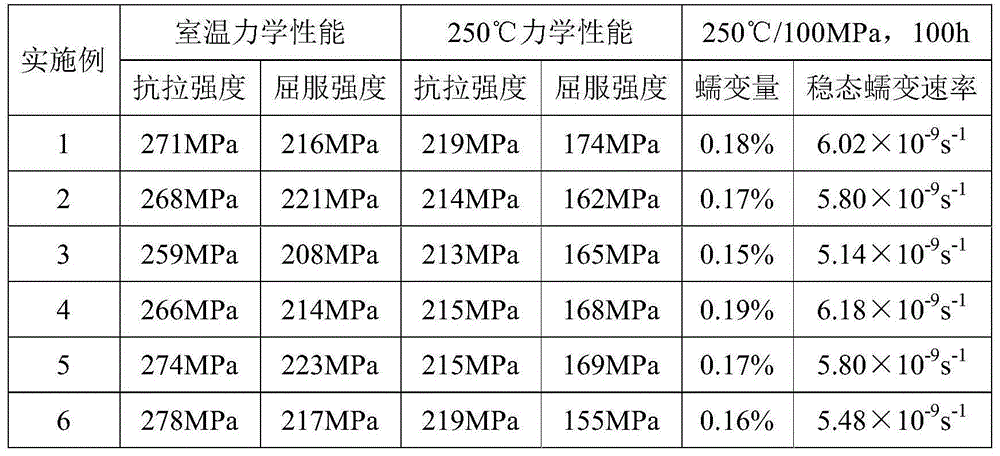

Examples

Embodiment 1

[0029] The creep-resistant rare earth magnesium alloy of this embodiment consists of the following components in mass percentage: 2.5% Sm, 1.8% Nd, 2.7% Gd, 1.5% Zr, 0.9% Ca, 1.2% Ag, 0.5% Sb, 0.4% Er, the balance is Mg and unavoidable impurities.

[0030] The preparation method of the creep-resistant rare earth magnesium alloy of the present embodiment comprises the following steps:

[0031] 1) Put raw materials pure magnesium, pure silver, pure antimony and master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca Dry and preheat in a drying oven at 200°C, and the preheating time is 2 hours;

[0032] 2) Put the preheated pure magnesium, pure silver and pure antimony in CO 2 +SF 6 Melt under the protection of mixed gas, add master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca when heated to 740°C, keep warm for 10min After the alloy is completely ...

Embodiment 2

[0036] The creep-resistant rare earth magnesium alloy of this embodiment consists of the following components in mass percentage: 3.6% Sm, 1.1% Nd, 1.3% Gd, 1.7% Zr, 1.1% Ca, 0.7% Ag, 0.7% Sb, 0.9% Er, the balance is Mg and unavoidable impurities.

[0037] The preparation method of the creep-resistant rare earth magnesium alloy of the present embodiment comprises the following steps:

[0038] 1) Put raw materials pure magnesium, pure silver, pure antimony and master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca Dry and preheat in a drying oven at 220°C, and the preheating time is 1.5h;

[0039] 2) Put the preheated pure magnesium, pure silver and pure antimony in CO 2 +SF 6 Melt under the protection of mixed gas, add master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca when heated to 730°C, keep warm for 10min After the alloy is completely mel...

Embodiment 3

[0043] The creep-resistant rare earth magnesium alloy of this embodiment consists of the following components in mass percentage: 4.2% Sm, 0.3% Nd, 3.1% Gd, 2.1% Zr, 0.2% Ca, 0.3% Ag, 0.9% Sb, 0.3% Er, the balance is Mg and unavoidable impurities.

[0044] The preparation method of the creep-resistant rare earth magnesium alloy of the present embodiment comprises the following steps:

[0045] 1) Put raw materials pure magnesium, pure silver, pure antimony and master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca Dry and preheat in a drying oven at 210°C, and the preheating time is 2 hours;

[0046] 2) Put the preheated pure magnesium, pure silver and pure antimony in CO 2 +SF 6 Melt under the protection of mixed gas, add master alloy Mg-Nd, master alloy Mg-Gd, master alloy Mg-Sm, master alloy Mg-Er, master alloy Mg-Zr, master alloy Mg-Ca when heated to 735°C, keep warm for 10min After the alloy is completely ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com